Injection molding manufacturing method for plastic worm wheel and injection molding die assembly

A technology of injection molding manufacturing and worm gear, which is applied to the injection molding manufacturing method of plastic worm gear and the field of injection mold components thereof, can solve the problems of unsuitable machining of hob, high processing cost, small size of hob, etc., and achieves improved meshing contact and injection molding. The effect of easy demolding and increased meshing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

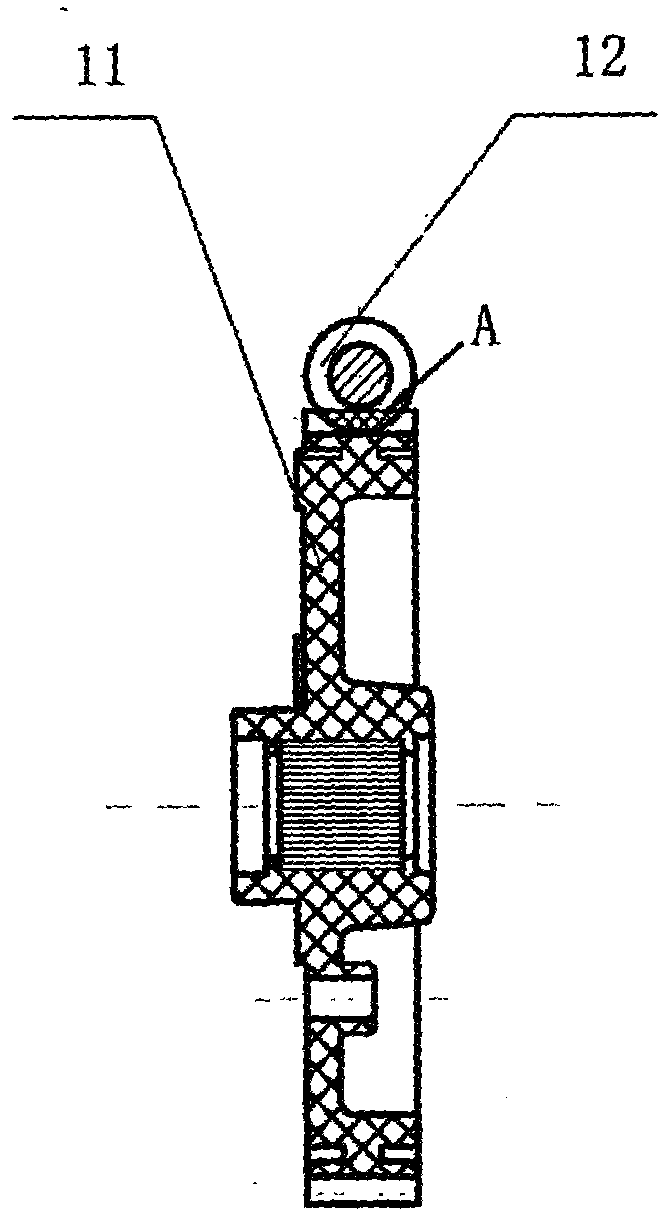

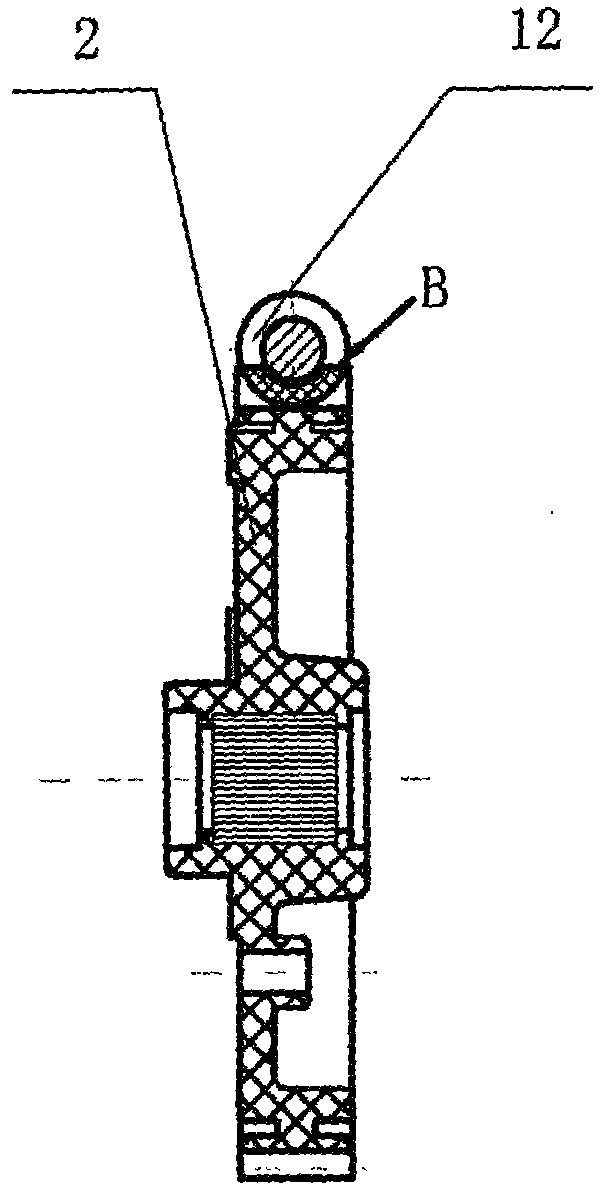

[0018] With reference to the accompanying drawings, the injection molding manufacturing method of the plastic worm gear of the present invention is: first, the left and right mold body components of the plastic worm gear mold body are subjected to a mold clamping process, and a number of worm gear fan-shaped tooth mold pieces 3 are inserted in the left mold body component 7 (this worm gear fan-shaped tooth mold piece also will be installed with right mold body assembly 9), the fan-shaped tooth-shaped end of this worm gear fan-shaped tooth-shaped mold piece can be combined into the profile of a plastic worm wheel (i.e. a piece of worm gear fan-shaped tooth-shaped mold piece Several tooth shapes of plastic worm gears are formed, and the combination of several worm gear fan-shaped tooth-shaped mold pieces forms all the tooth shapes of plastic worm gears and their synthesized ring gears), and each of the worm gear fan-shaped tooth-shaped mold pieces is powered by a corresponding mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com