Rotary plate-type fluidization coating equipment

A turntable, coating technology, applied in the direction of powder suspension granulation, etc., can solve the problem that the coating quality cannot be guaranteed, reduce the probability of spray sticking to the nozzle of the spray gun and the wall of the coating warehouse, and improve the utilization rate. rate, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

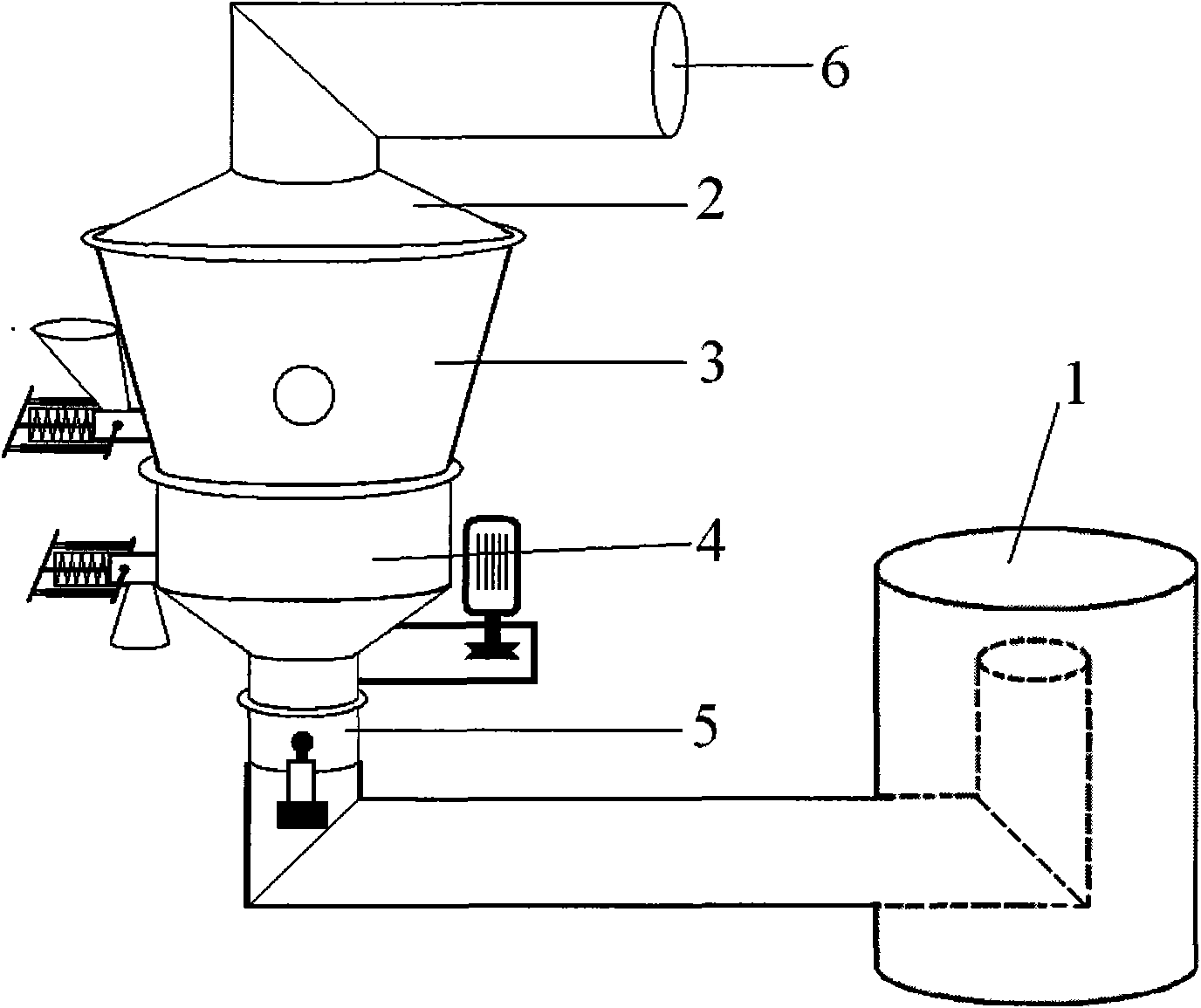

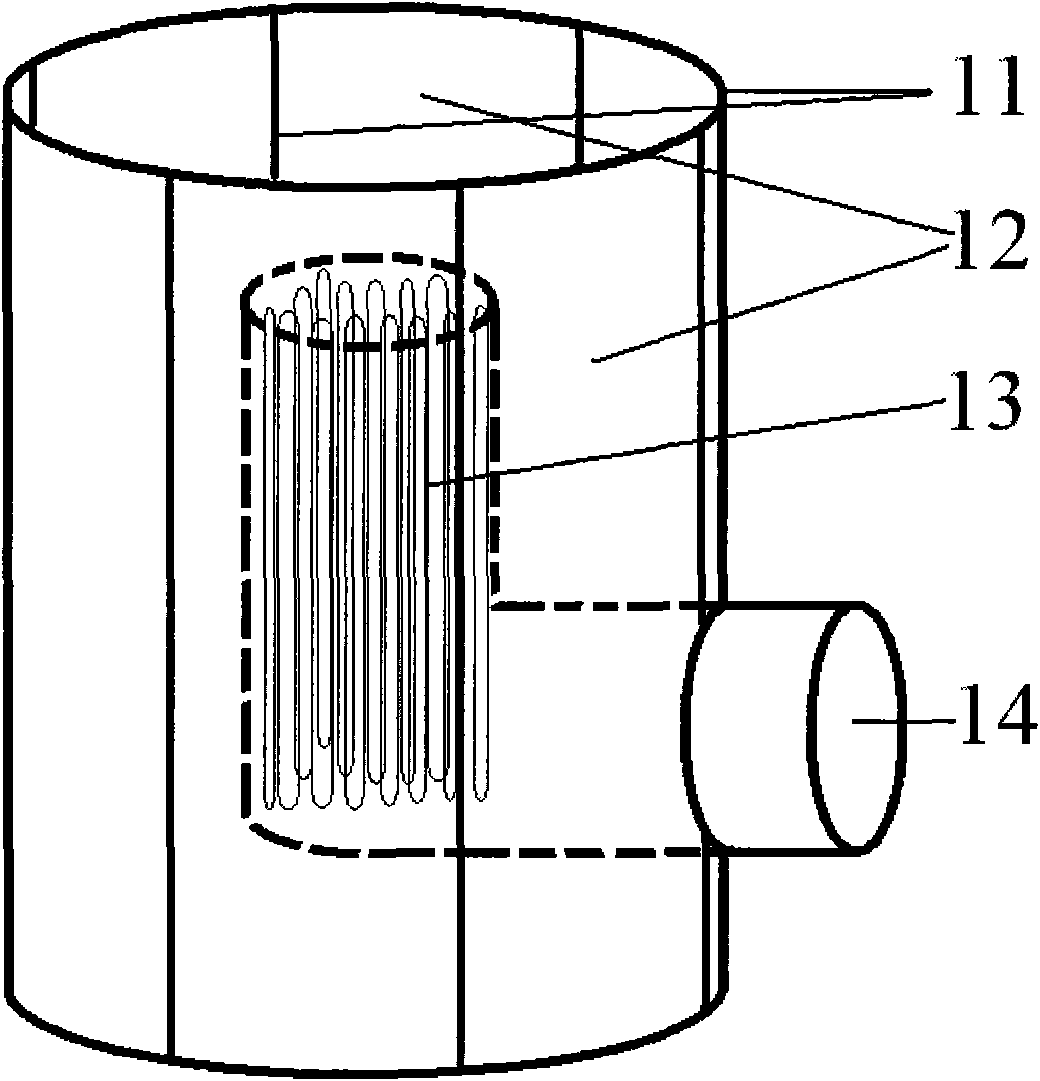

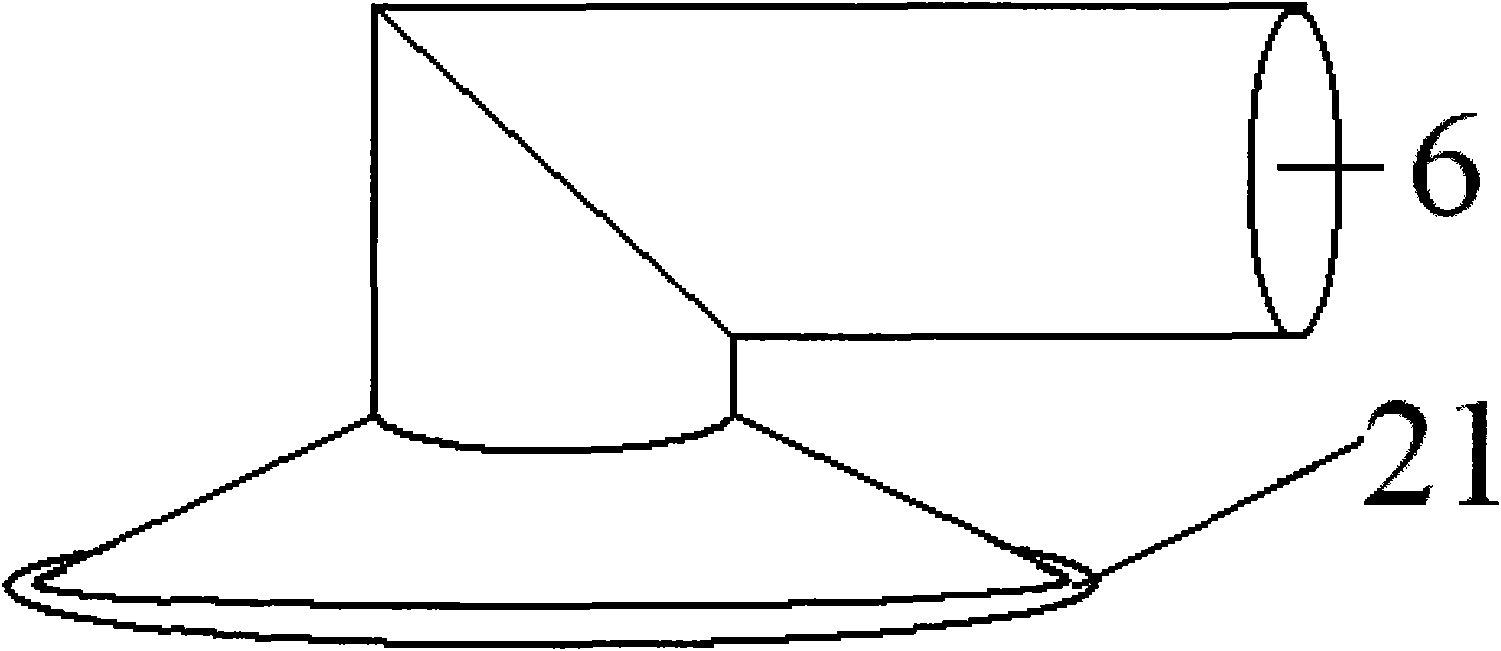

[0035]The present invention starts from ensuring the smooth flow of the pipeline of the whole set of equipment and increasing the fluidizing wind power, increasing the effective air inlet area of the air inlet of the heating equipment, increasing the aperture of the filter in the fluidized bed, and making the fluidizing effect of the particles in the fluidized state more obvious. Secondly, add axial strips on the wall of the fluidized bed to increase the impact on the fluidized particles and open the cohesive particles, and then add radial strips on the surface of the turntable to increase the driving force of the turntable on the particles, so that Particles rotate more fully. The intersection angle between the nozzle and the wall of the coating chamber is also optimized, so that the coating liquid is not easy to stick to the wall of the cylinder, and the waste of the coating liquid is reduced. Sharpens the structure at the spray gun tip, thereby reducing the chance of part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com