Film adhering method and device of wafer

A film sticking device and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inability to adjust wafer support force, difficulty in adjusting roller pressure, affecting wafer quality, etc., to reduce damage The risk of the wafer front side, the reduction of the risk of re-filming, and the effect of high film bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] like figure 1 As shown, the wafer attaching device includes a base 1 . Four seat legs (two seat legs 121 , 122 are shown in the figure) are installed on the lower surface of the base 1 for supporting the base 1 . The upper surface 11 of the base 1 is provided with a first groove (not shown in the figure) for accommodating the first platform 2 .

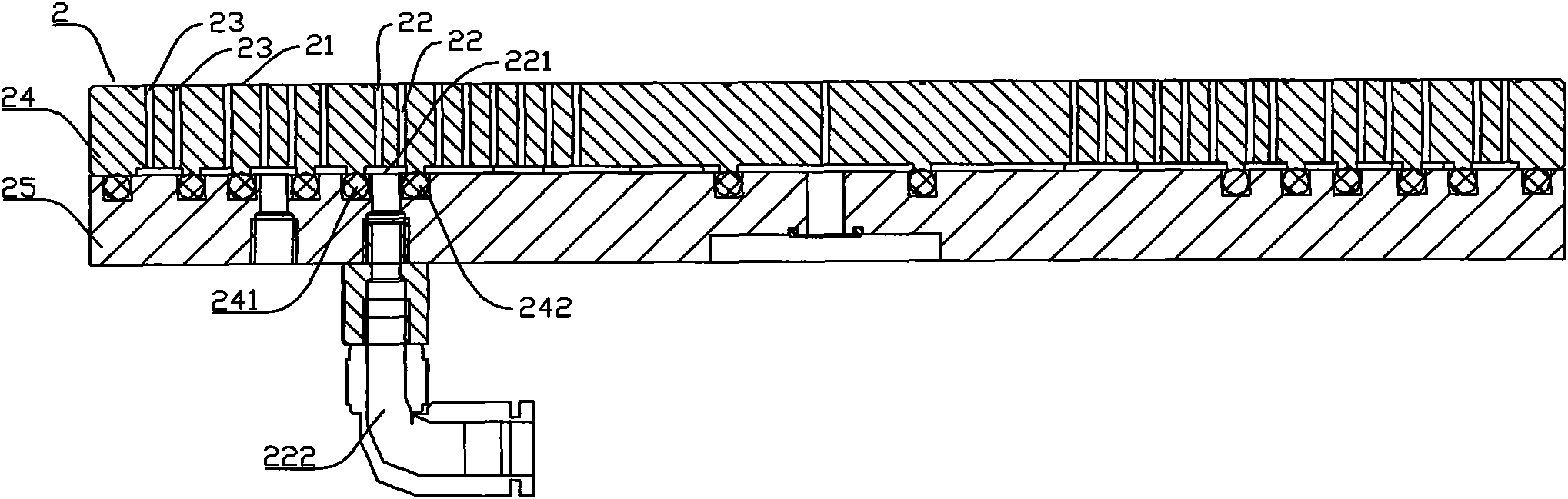

[0051] like figure 1 As shown, the first disc 2 is circular. The upper surface 21 of the first table 2 is provided with multiple turns of first air holes 22 , and the number of turns can be determined according to the diameter of the first table 2 . The number of first air holes 22 in each circle is more than two, which are evenly distributed along the circumferential direction, and the specific number can be determined according to the circumference. The first air hole 22 extends from the upper surface of the first platform 2 to the lower surface. The first air holes 22 are all communicated with an air compressor (not sho...

Embodiment 2

[0055] Figure 4 It is a structural schematic diagram of Embodiment 2 of the present invention. like Figure 4 As shown, the wafer attaching device includes a base 1 , and four legs are installed on the lower surface of the base 1 for supporting the base 1 . Figure 4 Only two seat legs (121, 122) are shown in .

[0056] The upper surface 11 of the base 1 is provided with a first groove (not shown in the figure). The first groove is used for accommodating the first disc 2 . The structure and usage of the first platform 2 are the same as those in Embodiment 1. The size of the first disk 2 is equivalent to that of a 12-inch wafer. The edge of the 12-inch wafer can be adsorbed and fixed on the first platform 2 through the second air hole 23 . Compressed air can be blown between the 12-inch wafer and the first platform 2 through the first air hole 22 to provide support for the 12-inch wafer.

[0057] The upper surface 21 of the first platform 2 is provided with a second gro...

Embodiment 3

[0069] The difference between this embodiment and Embodiment 2 is that the first platen 2 and the air cylinder are not provided. The second table 3 is arranged in the first groove of the base 1 , and the size of the first groove is adapted to the diameter of the second table 3 . All the other structures are identical with embodiment 2.

[0070] This embodiment is only suitable for attaching films to wafers of one size, but both non-contact and contact film attachments can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com