Suspending device for bridge detection working vehicle

A suspension device and bridge detection technology, which is applied in the direction of suspension, vehicle maintenance, elastic suspension, etc., can solve the problems of ineffective blockade, high center of gravity of the whole machine, and difficulty in carrying the load, so as to improve operation stability and safety , reduce the height of the center of gravity, and avoid the effect of self-falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

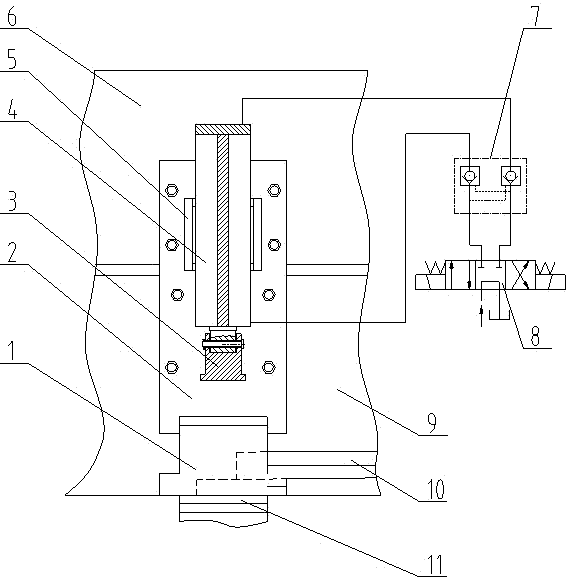

[0010] Such as figure 1 Shown, the present invention mainly is made up of rear axle leaf spring suspension device, bearing leveling seat 1, oil suspension device and frame assembly. The rear axle leaf spring suspension device is composed of two sets of leaf springs 10, and each set of leaf springs 10 is formed by overlapping and fixing multiple steel plates with different lengths. For a single rear axle, the two ends of each set of leaf springs 10 are connected to the chassis frame. 9 are connected, and the middle part is fixed on the vehicle axle 11; For double rear axles, the two ends of each group of leaf springs are then fixed on the two rear axles, and the middle part is fixed on the chassis frame 9. There are 2 or 4 load-bearing leveling seats 1, and each load-bearing leveling seat 1 is welded into a frame structure by multiple steel plates, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com