Four-joint visual robot

A robot, four-joint technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited application scope, high manufacturing cost, poor versatility, etc., to simplify the layout of the vision system, reduce construction costs, and facilitate placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

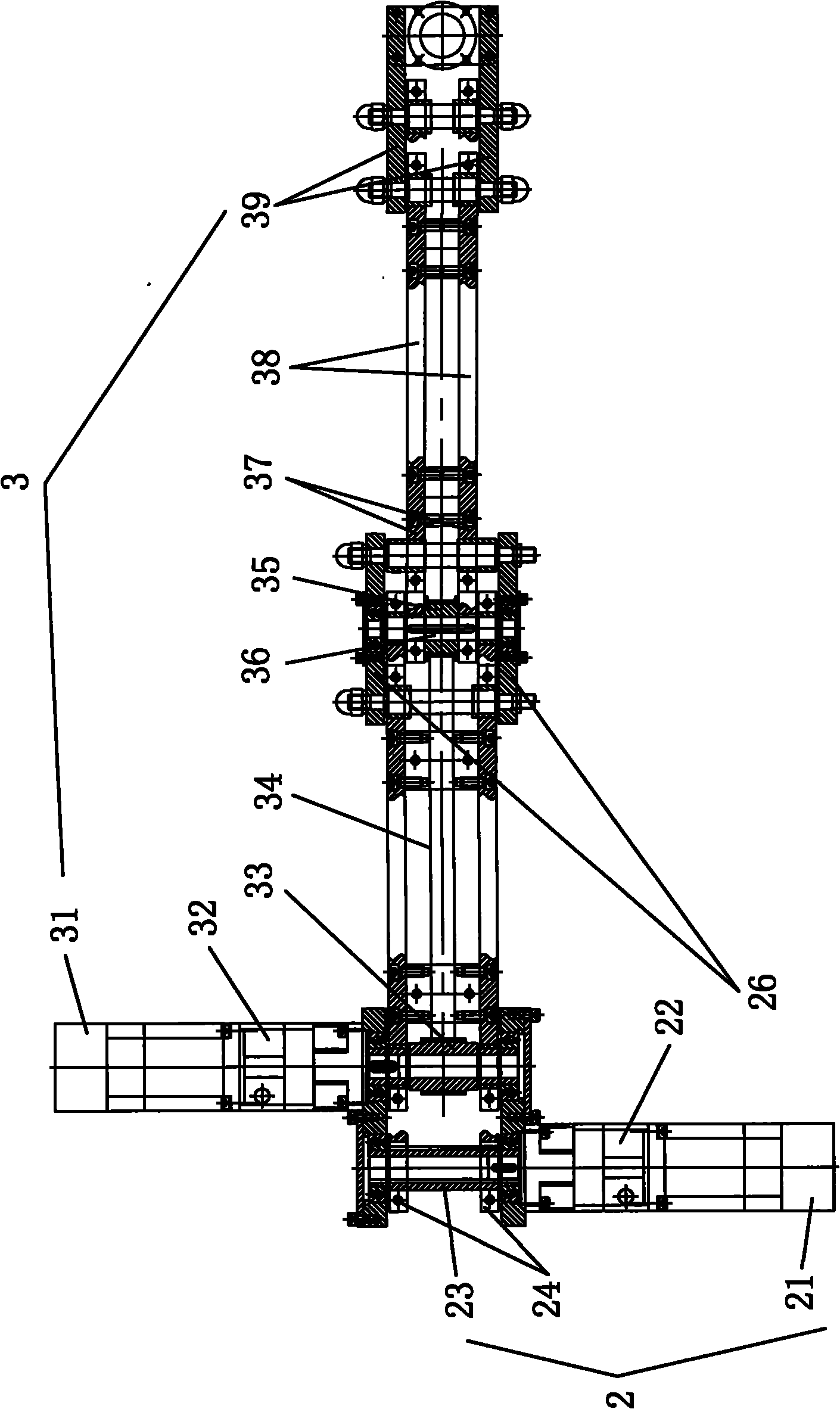

[0052] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0053] Such as Figure 1-Figure 4 The illustrated embodiment of the present invention is a four-joint vision robot. The robot includes: a waist-type base structure 1 including: a base 11; a motor 12: installed on the base 11, and the motor is controlled by a control system; Gear reducer 13: installed on the machine base in cooperation with motor 12, and its output shaft protrudes upwards out of the machine base; turntable 14: set above the machine base, and cooperates with the output shaft of the planetary gear reducer; base 15: set on the turntable The top is affixed to it; two bearing seats 16: are arranged on the top of the base 15 and are affixed to it; wherein, the motor 12 drives the planetary reducer 13 to transfer, and then drives the turntable 14, the base 15, and the bearing seat 16 to rotate 360 degrees.

[0054] Boom mechanism assembly 2 includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com