Special processed cheese for astronauts and production method thereof

A technology of processed cheese and production method, applied in the food field, can solve the problems of inconvenience of carrying, low nutrient content, unbalanced and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

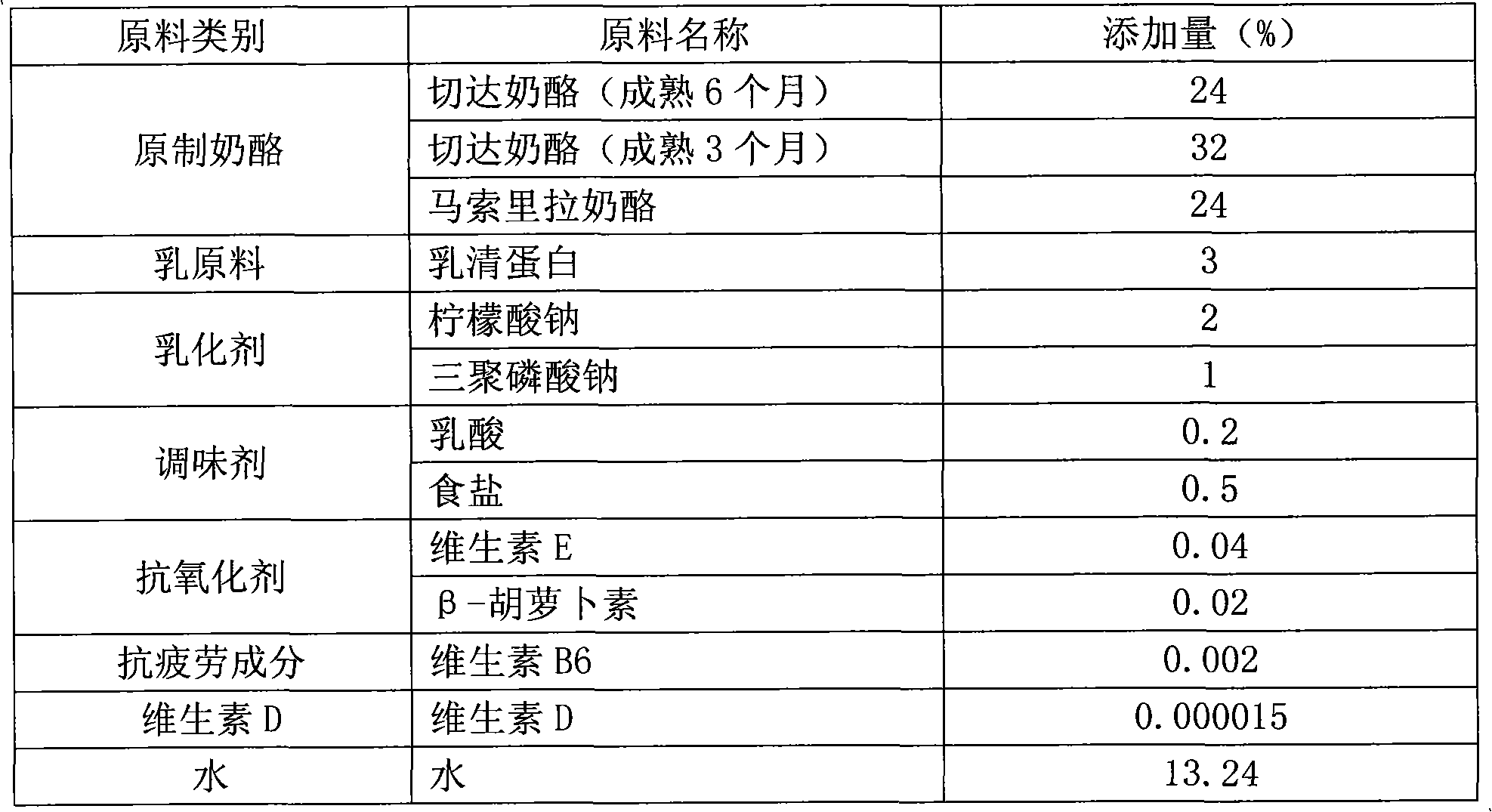

[0042] formula:

[0043]

[0044]

[0045] production method:

[0046] (1) Ingredients: Weigh all raw materials according to the formula (except antioxidant and anti-fatigue ingredients), wherein the original cheese and butter are cut into cubes with a side length of 5cm.

[0047] (2) Heating: Add the prepared raw materials into the melting pot, stir and mix for 2 minutes, and then directly heat to 85°C with steam.

[0048] (3) Sterilization: Sterilize by UHT, the sterilization temperature is 135°C, and the time is 9s;

[0049] (4) Cooling: Use flash evaporation or scraped surface heat exchanger to quickly cool down the product, and cool it to 90°C in 5 minutes;

[0050] (5) Emulsification: Stir in an emulsification tank at a low speed of 50 rpm for 8 minutes to increase the viscosity of the product and improve the texture of the product. In this operation link, the product temperature is about 85°C;

[0051] (6) Addition: Add sterilized antioxidants and anti-fatigue...

Embodiment 2

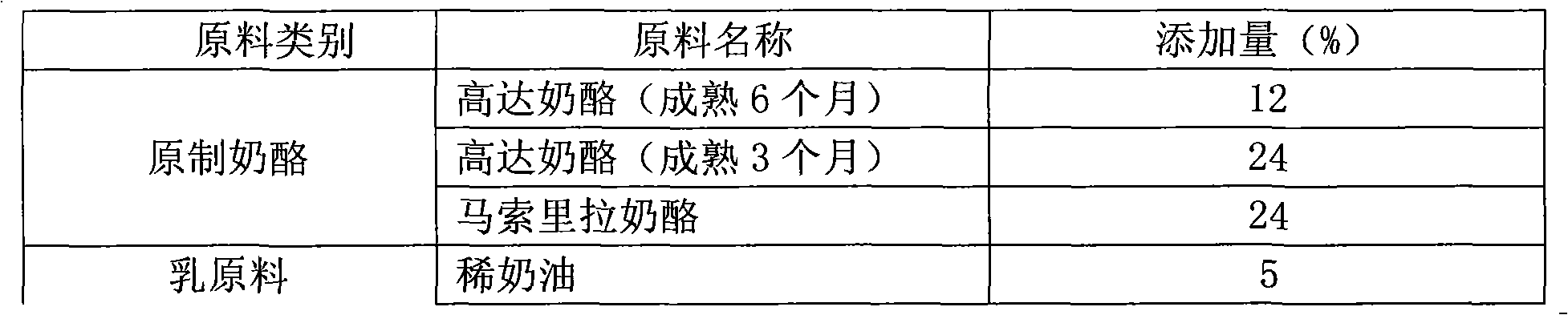

[0056] formula:

[0057]

[0058]

[0059] production method:

[0060] (1) Ingredients: Weigh all raw materials (except antioxidants and anti-fatigue ingredients) according to the formula, wherein the original cheese and butter are cut into cubes with a side length of 7cm.

[0061] (2) Heating: Add the prepared raw materials into the melting pot, stir and mix for 1.5 minutes, and then directly heat to 80°C with steam.

[0062] (3) Sterilization: Sterilize by UHT, the sterilization temperature is 140°C, and the time is 4s;

[0063] (4) Cooling: use flash or scraped surface heat exchanger to quickly cool down the product, and cool it to 93°C in 4 minutes;

[0064] (5) Emulsification: Stir in an emulsification tank at a low speed of 60 rpm for 3 minutes to increase the viscosity of the product and improve the texture of the product. In this operation link, the product temperature is about 85°C;

[0065] (6) Addition: Add sterilized antioxidants and anti-fatigue ingredie...

Embodiment 3

[0071] formula:

[0072]

[0073] production method:

[0074] (1) Ingredients: Weigh all raw materials (except antioxidants and anti-fatigue ingredients) according to the formula, wherein the original cheese and butter are cut into cubes with a side length of 10cm.

[0075] (2) Heating: Add the prepared raw materials into the melting pot, stir and mix for 2 minutes, and then directly heat to 95°C with steam.

[0076] (3) Sterilization: Sterilize by UHT, the sterilization temperature is 137°C, and the time is 6s;

[0077] (4) Cooling: Use flash evaporation or scraped surface heat exchanger to quickly cool down the product, and cool it to 92°C in 3 minutes;

[0078](5) Emulsification: Stir in an emulsification tank at a low speed of 40 rpm for 9 minutes to increase the viscosity of the product and improve the texture of the product. In this operation link, the product temperature is about 85°C;

[0079] (6) Addition: Add sterilized antioxidants and anti-fatigue ingredient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com