Triaxial cell for the testing of geomaterials in compression and in tension

A geotechnical material, test room technology, applied in the direction of using stable tension/pressure to test material strength, material inspection items, analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

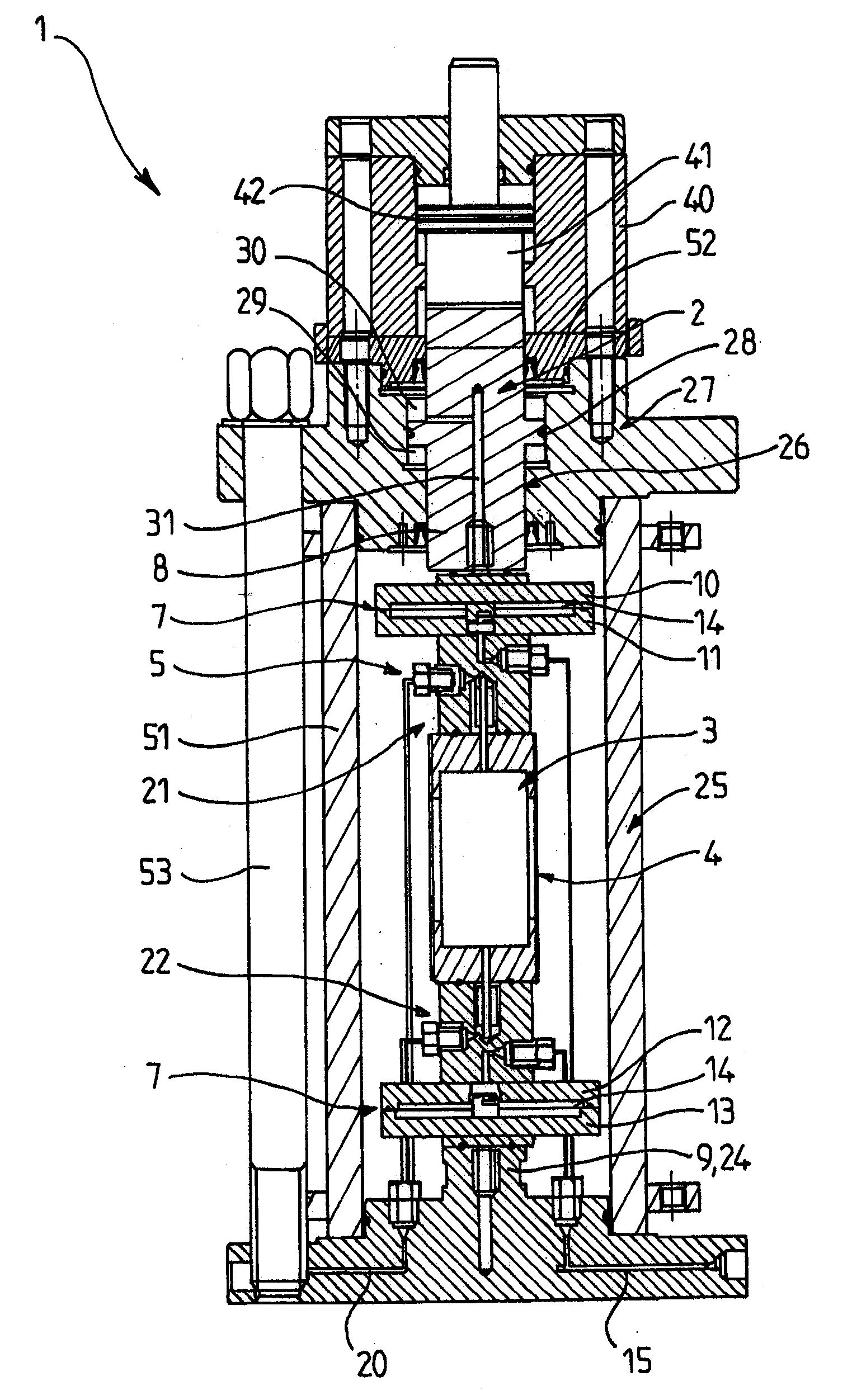

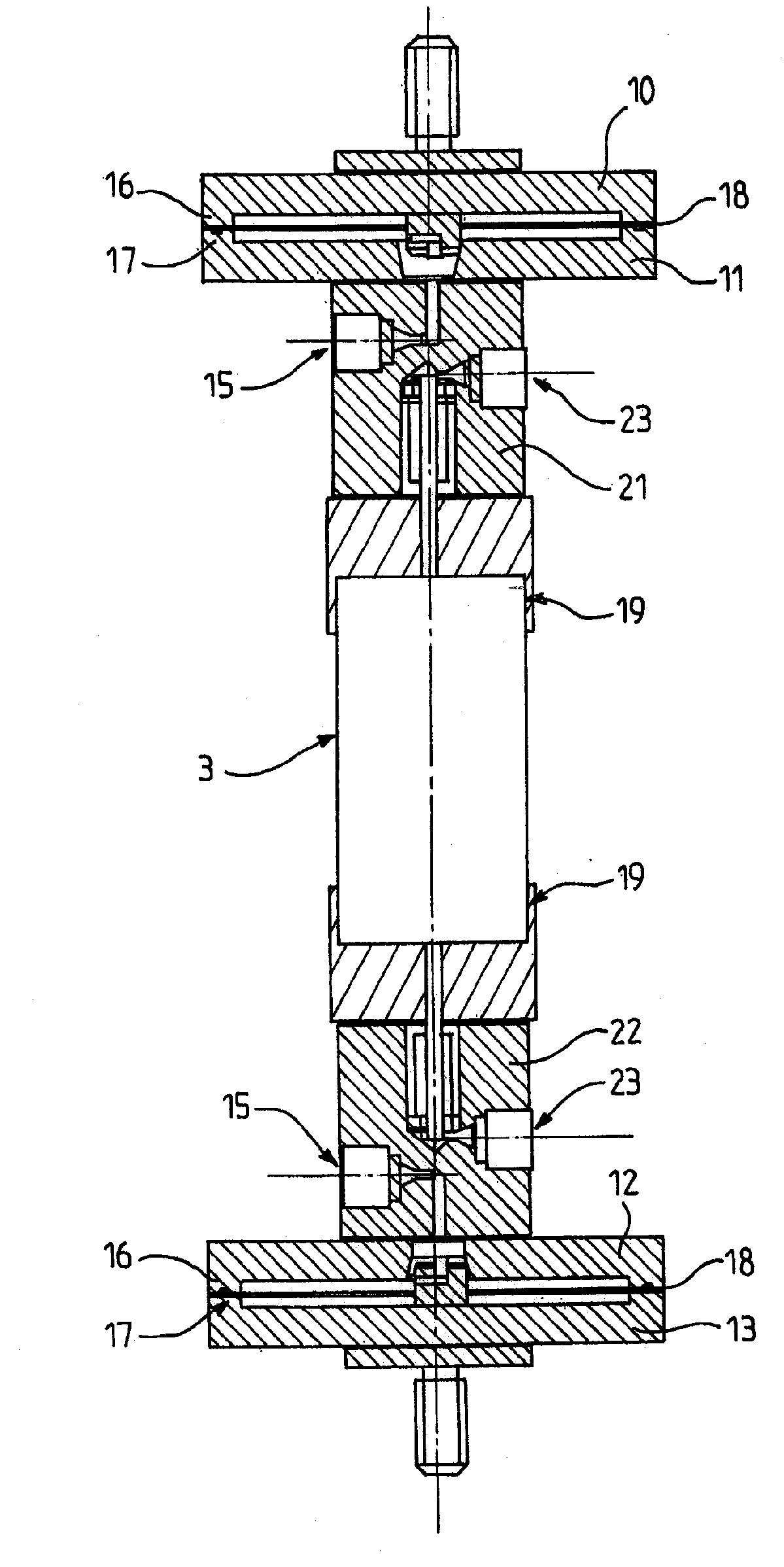

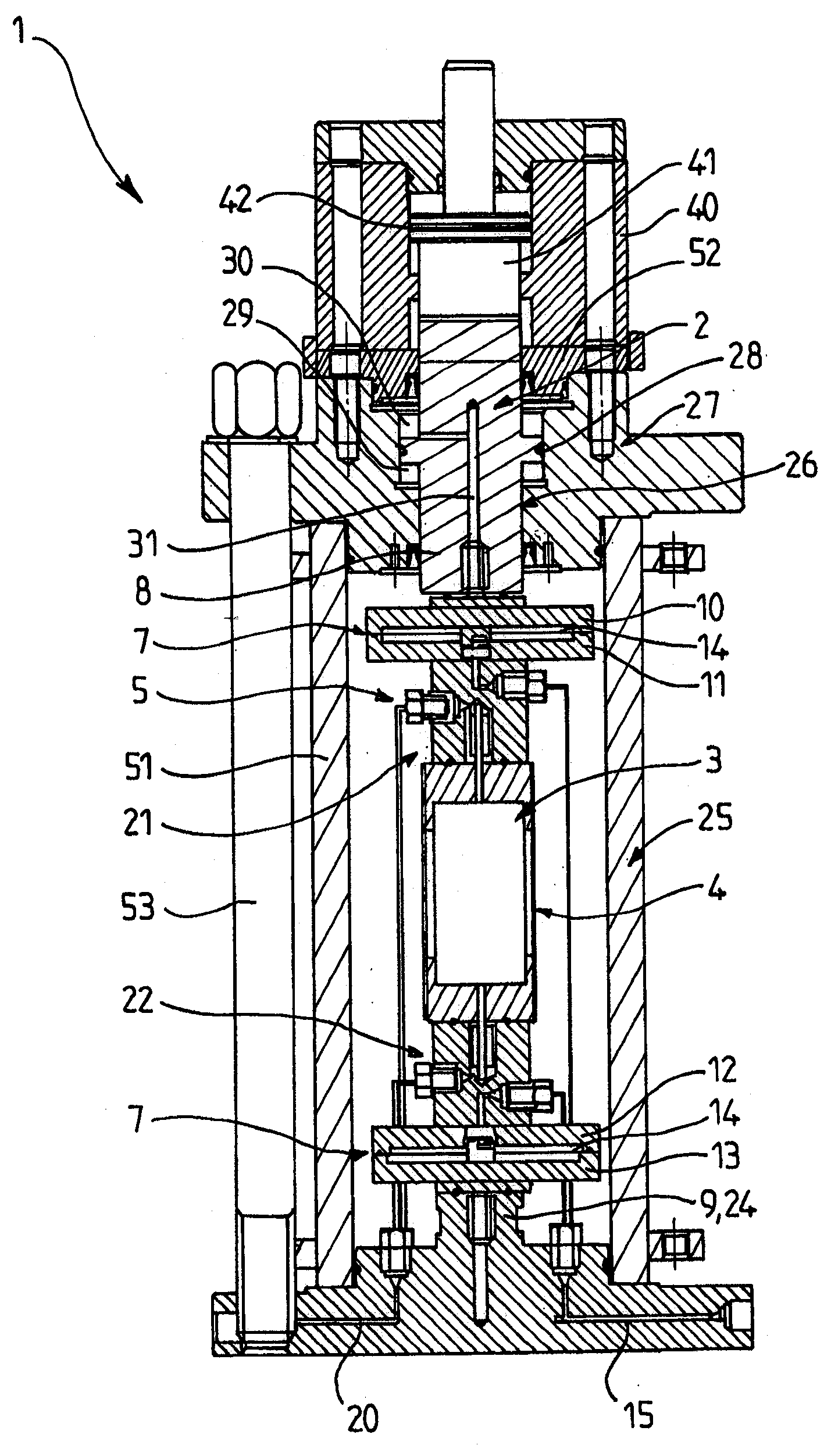

[0036] The present invention relates to a triaxial unit for conducting geotechnical material tests on samples such as rock, soil or manufacturing materials, which includes:

[0037] At least one piston 2 for subjecting the specimen 3 to stress directed along the longitudinal axis of the specimen;

[0038] Hydraulic device, used to make the side wall of the sample 3 under fluid pressure, if necessary, through the elastic shell 4 that wraps the side wall of the sample 3 subject to particularly radial stress;

[0039] The hydraulic device includes: at least one sealed test chamber 5 into which a sample is introduced; and a circuit for pressurizing and controlled discharge of the test chamber with a so-called pressurized fluid.

[0040] According to the present invention, the unit includes a device 7 for constraining the specimen in tension, the device 7 being configured to detachably fix the specimen between two attachments 8, 9 which 8 and 9 are used to move away from or close to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com