Dual clutch

A dual-clutch, clutch housing technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve problems such as hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

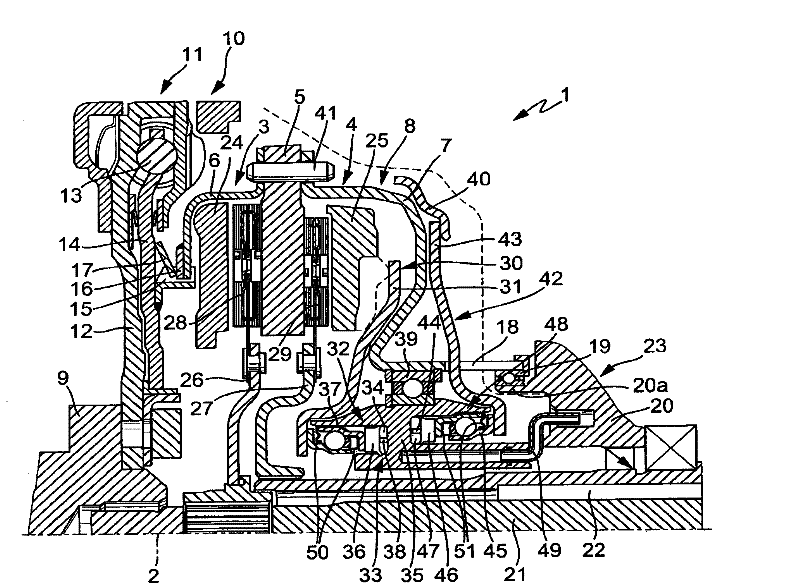

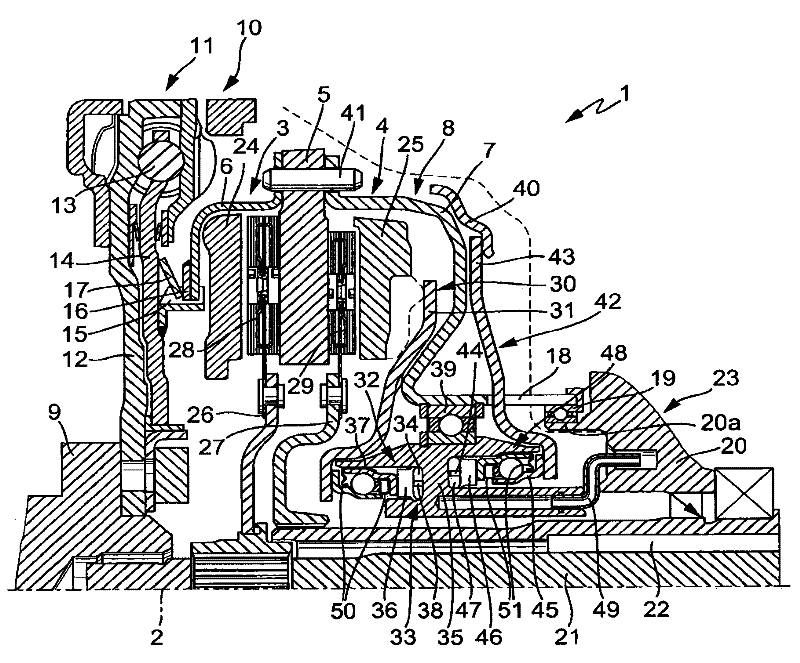

[0030] figure 1 A dual clutch 1 is shown in partial section above its axis of rotation 2 . The dual clutch 1 comprises two friction clutches 3 , 4 which have a common central pressure plate 5 which is fixedly connected to the housing parts 6 , 7 of the clutch housing 8 . The clutch housing 8 is driven by a crankshaft 9 of a not shown internal combustion engine. To this end, in the exemplary embodiment shown, a torsional vibration damper 10 —here in the form of a dual-mass flywheel 11 —is connected with its input part 12 to the crankshaft 9 . The output part 14, which can be twisted to a limited extent relative to the input part 2 against the action of the energy store 13, has a forwardly protruding tooth profile 15 in which a complementary tooth profile 16, such as that of the housing part 6 shown, engages. An internal tooth section. In the exemplary embodiment shown here, the dual clutch 1 is held relative to the crankshaft 9 and relative to the torsional vibration damper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com