Method for checking welding quality of stator winding joint of large power generator

A technology for generator stator and welding quality, which is applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the problems of welding joint resistance beyond the accurate measurement range, damage to the insulation layer of the wire rod, and narrow space for the wire rod, etc. Achieve the effect of improving accuracy, ensuring accuracy, and high current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

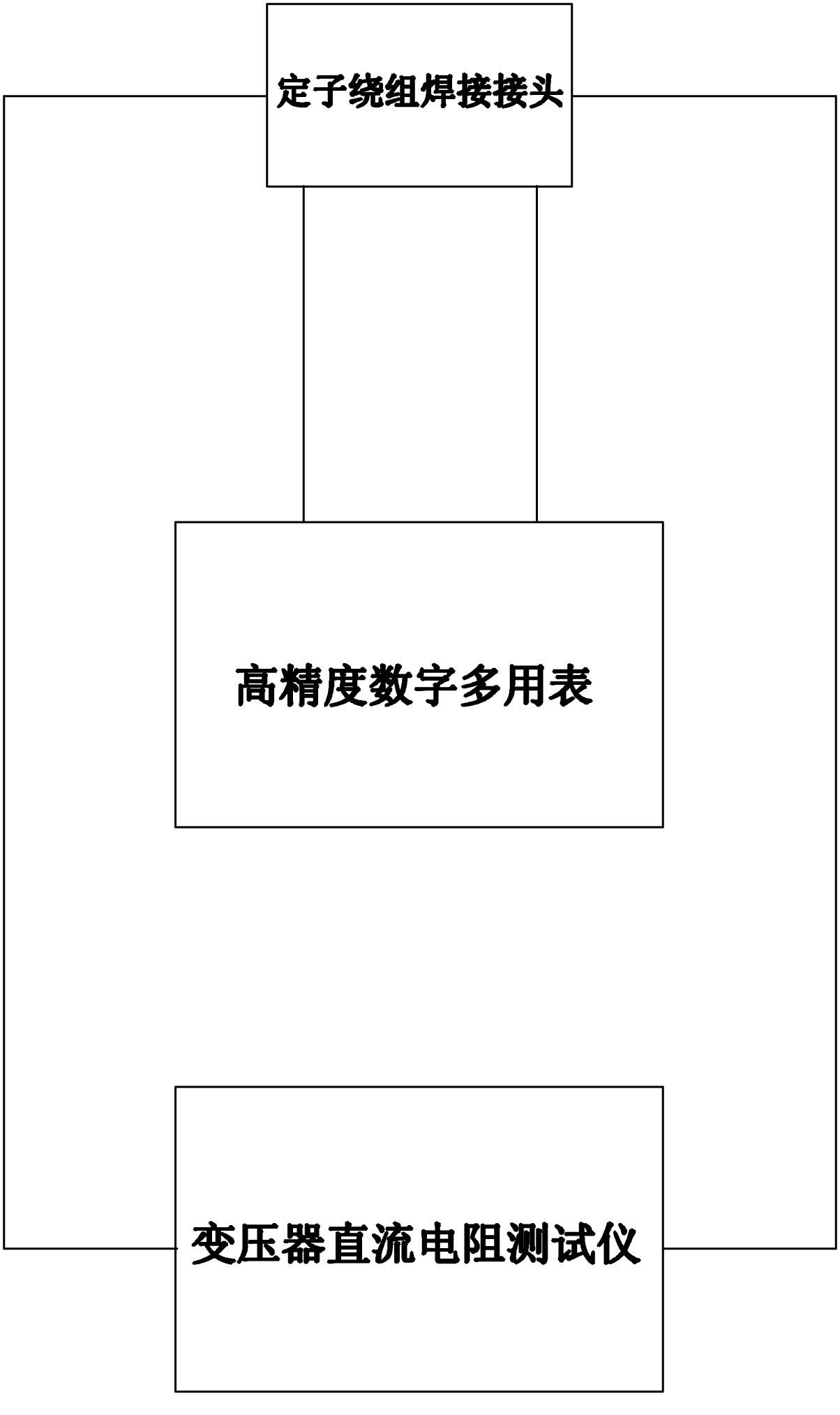

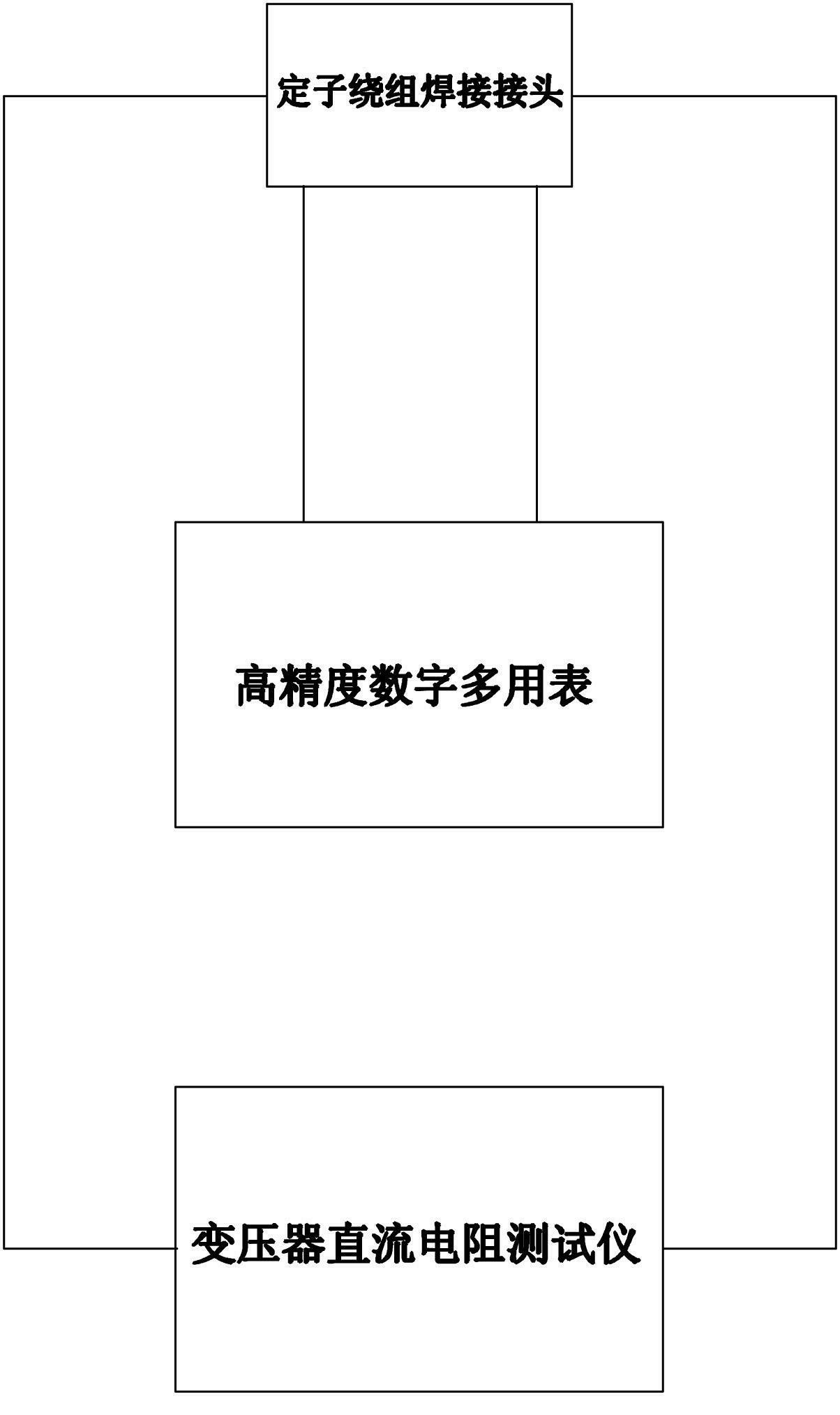

[0017] A method for checking the welding quality of large generator stator winding joints, comprising the following steps:

[0018] 1) Output a constant 50A DC current through a 50A transformer DC resistance tester and connect it to both ends of the stator winding connector;

[0019] 2) To measure the current, use a 0.2A class shunt and a DC voltmeter to monitor the DC current value;

[0020] 3) Use a high-precision digital multimeter to measure the voltage at both ends of the joint resistance, and convert it into a resistance value;

[0021] Through the above method, the measurement accuracy of the stator winding joint resistance can reach 0.2μΩ.

[0022] The output current of the 50A transformer DC resistance tester is 5A, 10A, 20A and 50A.

[0023] The accuracy of the 50A transformer DC resistance tester is 0.2%.

[0024] The measuring range of the high-precision digital multimeter is 0-90mV.

[0025] The resolution of the high-precision digital multimeter is 10 μV.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com