High-speed spindle on-line automatic balancing experiment system

A high-speed motorized spindle and experimental system technology, applied in static/dynamic balance testing, measuring devices, instruments, etc., can solve the problems of complex data acquisition process, low spindle speed, and reduced calculation accuracy, and achieve high system experimental accuracy, The effect of high degree of automation and high balancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

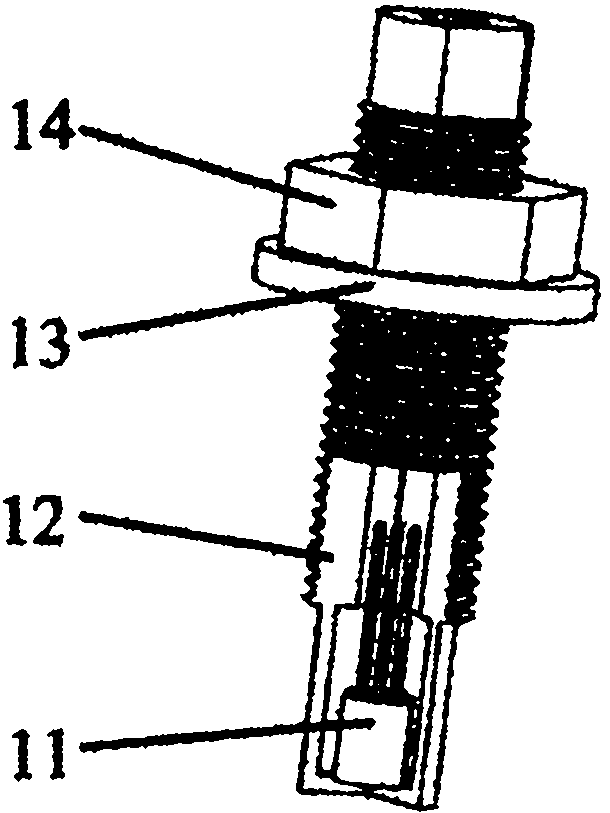

[0041] see Figure 1-4 , the present invention includes a mechanical part and an electrical control part. The high-speed electric spindle 1 of the mechanical part is installed on the shock-absorbing workbench 15 through the base 2, and the high-speed electric spindle 1 spindle rotor adopts two pairs of centripetal angular contact rolling ball bearings. Support, the high-speed electric spindle 1 spindle motor is installed between two pairs of bearings, the high-speed electric spindle 1 is equipped with a temperature sensing device 10, and the protruding ends on both sides of the high-speed electric spindle 1 are installed with eddy current displacement sensors 8 from inside to outside And the online dynamic balance device, the phase of the installation of the eddy current displacement sensor 8 can be adjusted according to the needs of the algorithm, and the ends of the two ends of the high-speed electric spindle 1 are provided with tapered holes for installing the imbalance simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com