Embedded bolt cleading

A technology of pre-embedded bolts and sets of plates, which is applied in construction, building construction, etc., can solve the problems of waste of raw materials, easy shaking, loose bolts, etc., and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

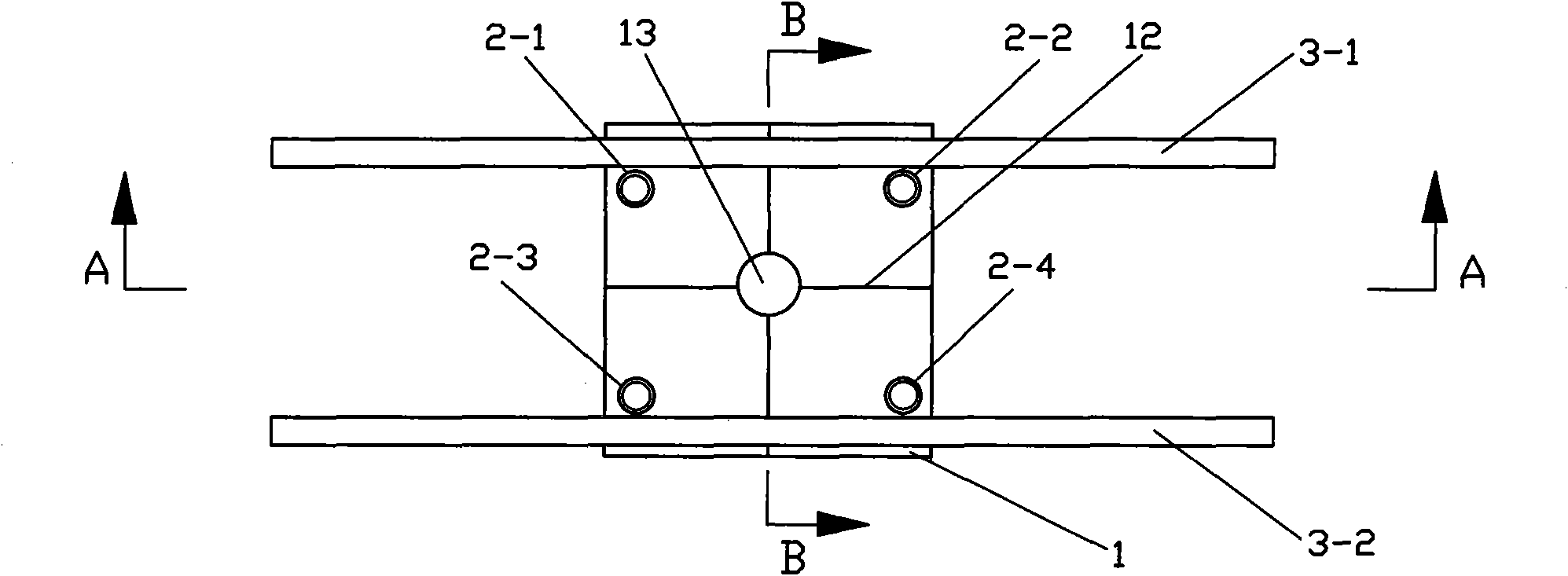

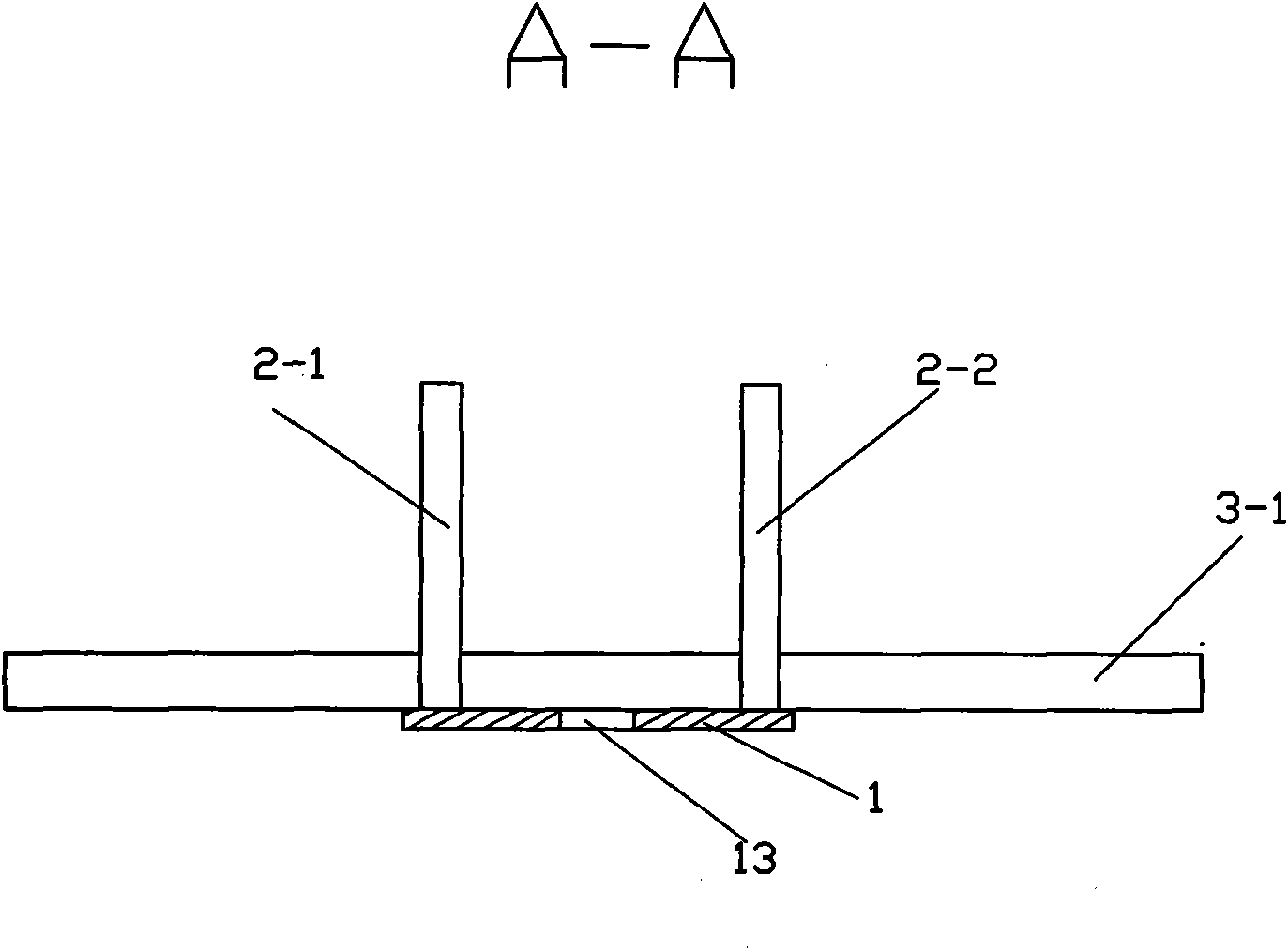

[0016] See Figure 1 to Figure 4 , The pre-embedded bolt sleeve plate of this embodiment includes a square steel plate 1, a galvanized pipe 2 and a connecting steel pipe 3. The steel plate 1 is drilled with four centrally symmetrical positioning holes 11-1, 11-2, 11-3, 11-4. A cross axis 12 is engraved on the steel plate 1 .

[0017] The thickness of the steel plate 1 is 10 mm. In order to ensure the construction quality, it should be confirmed that the steel plate has no deformation, warpage, etc.

[0018] The number of positioning holes 11 of the steel plate 1 is the same as the number of embedded bolts, so the steel plate 1 of this embodiment is suitable for pouring of foundation concrete columns with 4 embedded bolts. The center spacing of the four positioning holes 11-1, 11-2, 11-3, and 11-4 should meet the design requirements, that is, meet the design requirements for the position and spacing of the embedded bolts.

[0019] The steel plate 1 is also provided with a vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com