Environment-friendly backfire clean coking and gas making and electricity generating polygeneration device

An environmentally friendly, polygeneration technology, applied in coke ovens, combustible gas production, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

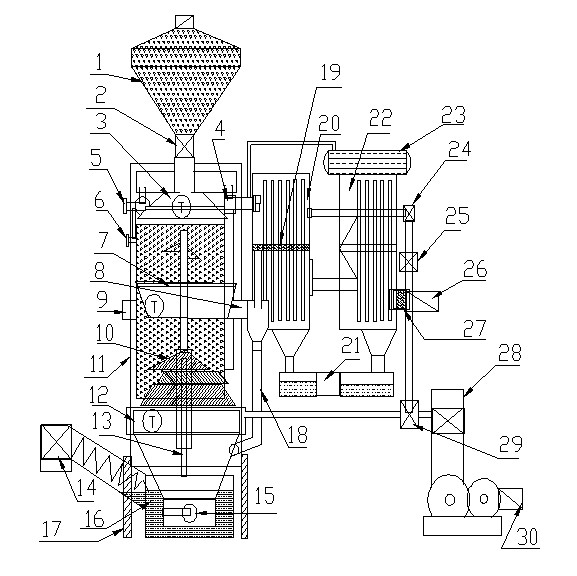

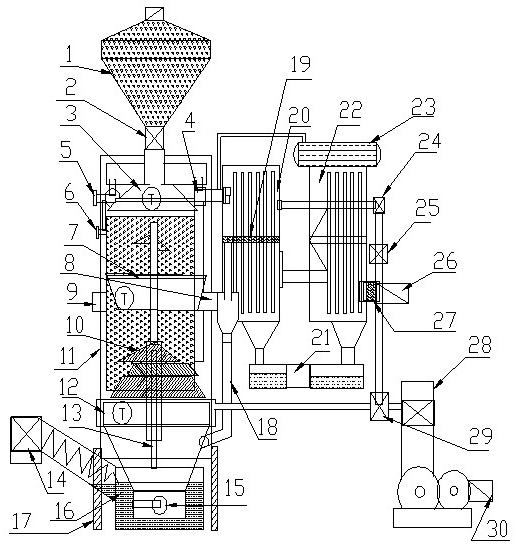

[0017] Such as figure 1 As shown, the environment-friendly anti-fire pressurized clean coking and gas generation polygeneration device includes a storage bin 1, a controller 2 for the amount of material entering the furnace, a first gasification steam input component 3, and a second primary gasification steam input assembly. Gasification steam input assembly 4, first high temperature air gasification agent inlet 5, second high temperature air gasification agent inlet 6, first gas output assembly 7, second gas output assembly 8, safety explosion vent 9, special high temperature steel The charcoal discharge grate 10, the water wall 11, the secondary gasification hot air inlet 12, the first charcoal discharge control system 13 that can control the amount of charcoal discharge, the second charcoal discharge detection and control mechanism 14, and the central microprocessor Temperature transmitter 15, furnace shell with water cooling jacket 16, base bracket 17, cyclone dust collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com