Preparation method of pigment yellow 138

A pigment yellow and crude product technology, applied in the field of preparation of pigment yellow 138, can solve the problems of difficult recycling and incompleteness, and achieve the effects of low environmental pollution, high raw material utilization rate, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

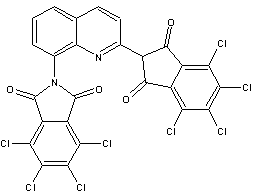

Image

Examples

Embodiment 1

[0020] The preparation method of Pigment Yellow 138 comprises synthesis steps and pigmentation steps:

[0021] The synthesis steps are as follows: add 480g of benzoic acid into a reactor with heating and stirring, heat up to 125°C to melt it, start stirring, add 87g of tetrachlorophthalic anhydride and 16g of 8-aminoquinaldine in sequence, and react at 160°C for 3 hours , then heated up to 220°C for 2 hours, cooled the reactant to 130°C, poured it into 840g of 20% sodium hydroxide solution within 0.5h, reacted for 20min, filtered, washed, and dried to obtain 63.8g of crude pigment yellow 138 , The filtrate recovered 478.3 g of benzoic acid and unreacted tetrachlorophthalic anhydride after acid analysis.

[0022] The pigmentation step is: add 300 g of DMF to a reactor with heating and stirring and a reflux condenser, start stirring, add 20 g of the crude product of Pigment Yellow 138 and 1 g of sodium dodecylbenzene sulfonate, and after dispersing evenly, in 0.5 Add 10g of 30%...

Embodiment 2

[0025] The preparation method of Pigment Yellow 138 comprises synthesis steps and pigmentation steps:

[0026] The synthesis steps are as follows: add 320g of benzoic acid into a reactor with heating and stirring, heat up to 127°C to melt, start stirring, add 60g of tetrachlorophthalic anhydride and 16g of 8-aminoquinaldine in sequence, and react at 140°C for 2 hours , then raised the temperature to 180°C for 3 hours, cooled the reactant to 130°C, poured it into 960g of 10% sodium hydroxide solution within 40min, reacted for 10min, filtered, washed and dried to obtain 65.7g of crude pigment yellow 138, The filtrate recovered 303.4 g of benzoic acid and unreacted tetrachlorophthalic anhydride after acid analysis.

[0027] The pigmentation step is as follows: add 600 g of o-dichlorobenzene into a reactor with heating and stirring and a reflux condenser, start stirring, add 20 g of the above-mentioned crude product of Pigment Yellow 138, and after the dispersion is uniform, add 6...

Embodiment 3

[0030] The preparation method of Pigment Yellow 138 comprises synthesis steps and pigmentation steps:

[0031] The synthesis steps are as follows: add 160g of benzoic acid to a reactor with heating and stirring, heat up to 130°C to melt it, start stirring, add 70g of tetrachlorophthalic anhydride and 16g of 8-aminoquinaldine in sequence, and react at 180°C for 1 hour , then heated up to 200°C to react for 4h, cooled the reactant to 130°C, poured it into 1200g 5% sodium hydroxide solution within 1h, reacted for 1h, filtered, washed and dried to obtain 66.9g of crude pigment yellow 138, The filtrate recovered 154.8 g of benzoic acid and unreacted tetrachlorophthalic anhydride after acid analysis.

[0032] The pigmentation step is as follows: add 100 g of N-methylpyrrolidone into a reactor with heating and stirring and a reflux condenser, start stirring, add 20 g of the above-mentioned crude product of Pigment Yellow 138, and after dispersing evenly, add 30% sodium methoxide with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com