Ion beam figuring processing method for aspheric surface processing

A processing method and ion beam technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass cutting devices, etc., can solve the problems of complex operation, high preparation cost, processing efficiency and processing effect to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

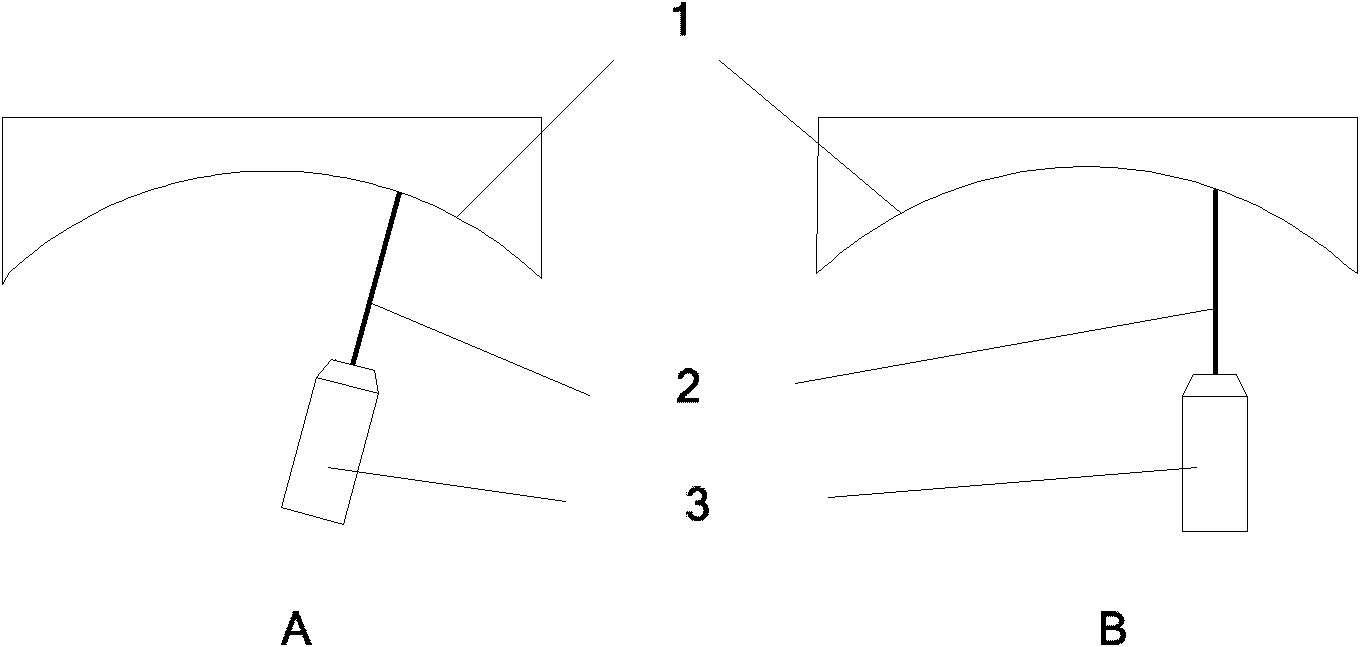

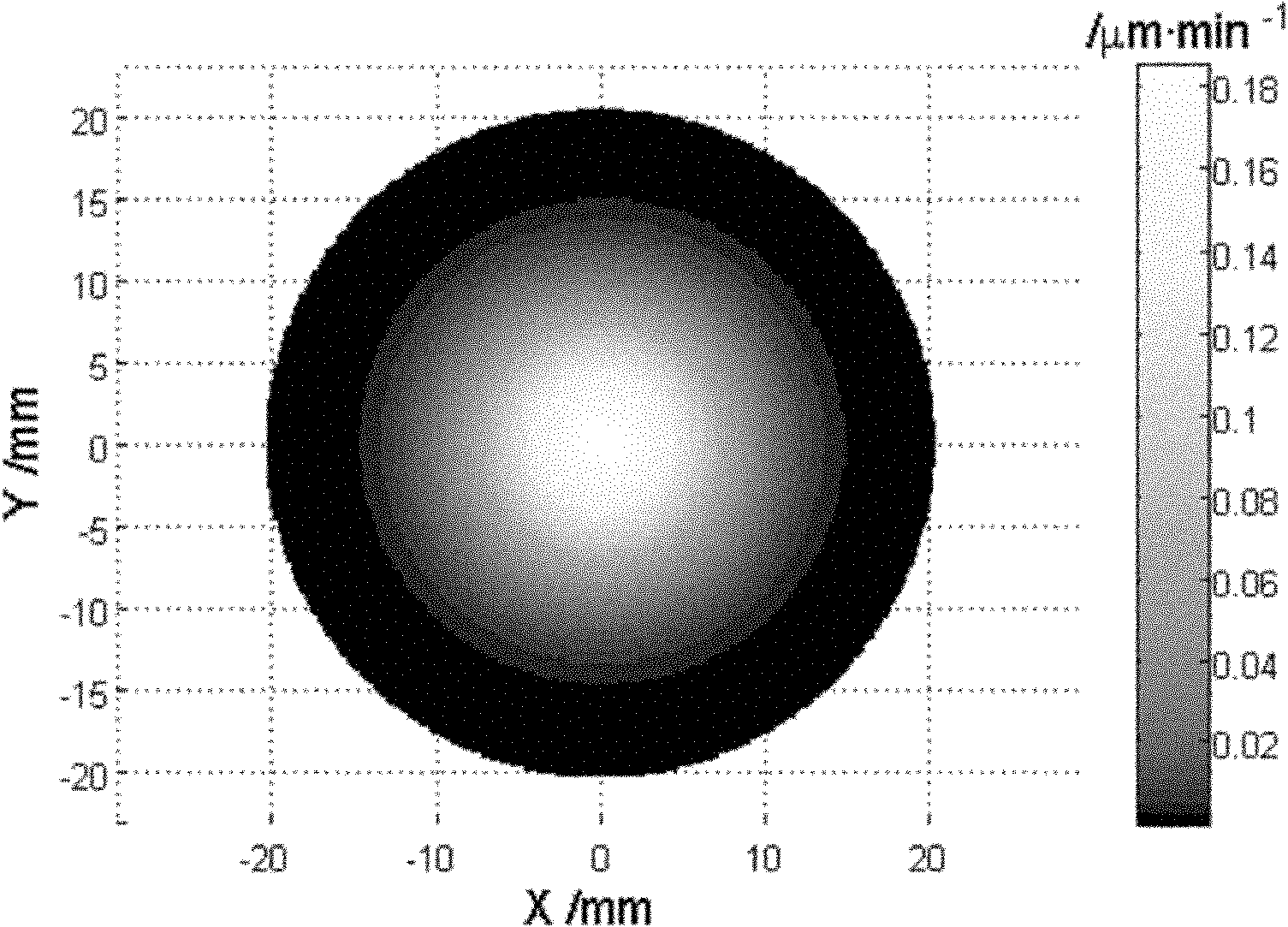

[0057] The ion beam polishing process of this embodiment is carried out on an ordinary ion beam polishing equipment, and its process parameters are: the working gas is argon, and the working vacuum is 0.8×10 -2 Pa, ion energy 800eV, beam current 25mA. The optical element to be processed is an off-axis aspheric mirror with a size of 250mm×90mm, and the material is ordinary glass ceramics; the off-axis distance of the mirror surface is 16mm, the curvature radius of the vertex is 285mm, and the eccentricity is 0.93. The mirror surface has undergone traditional optical polishing, but the surface shape error is still large, which cannot meet the requirements. The following uses the ion beam modification processing method of the present invention to carry out ion beam modification processing to the aspheric mirror, and the specific operation steps are as follows:

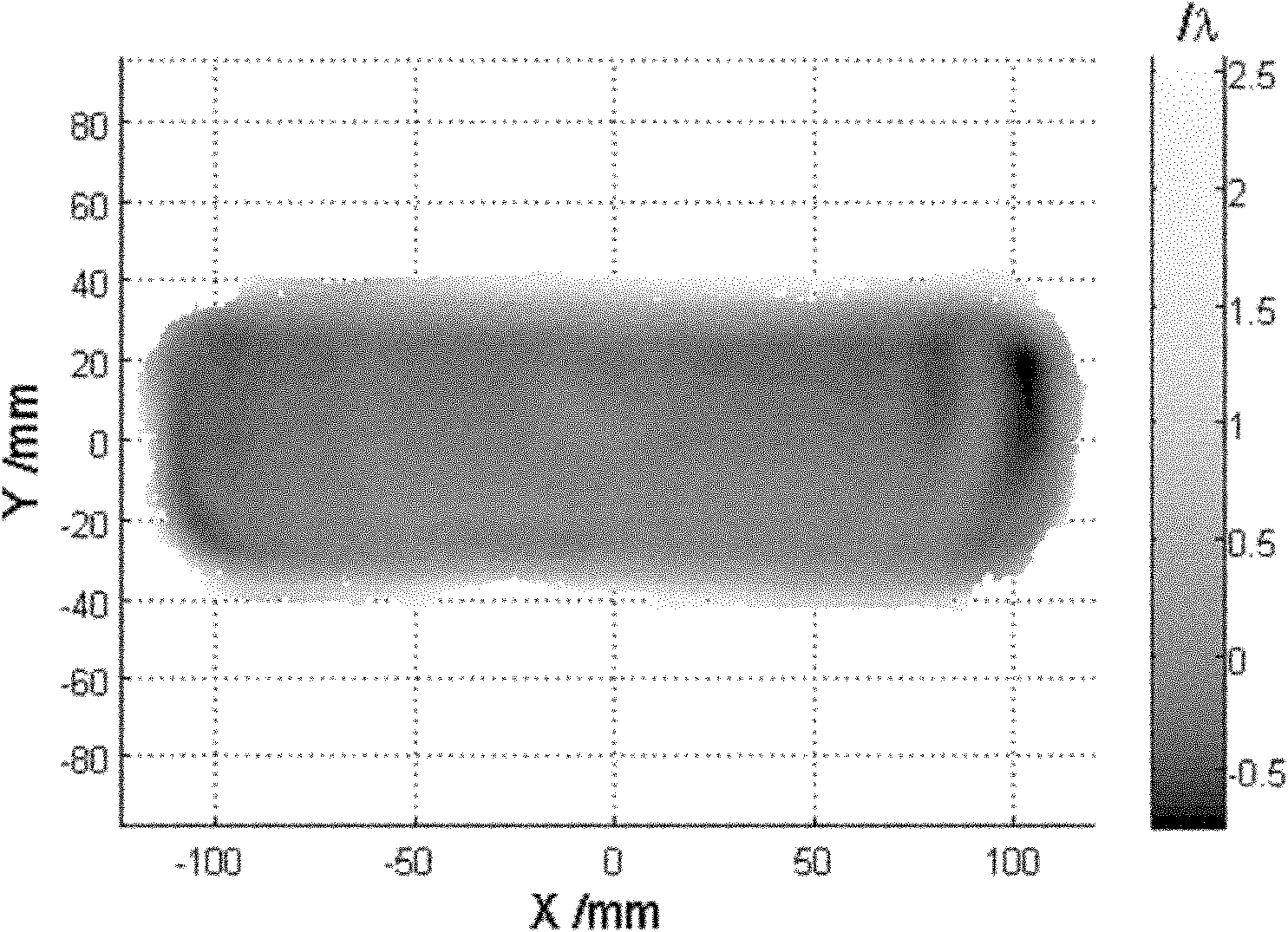

[0058] 1. Detection of surface error: Use laser interferometer to detect the surface error of the mirror surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com