Servo automatic sequence bottle unscrambler

A technology of automatic sequence and bottle unscrambler, which is applied in the direction of packaging bottles, packaging, and packaging item types. The effect of the bottle phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

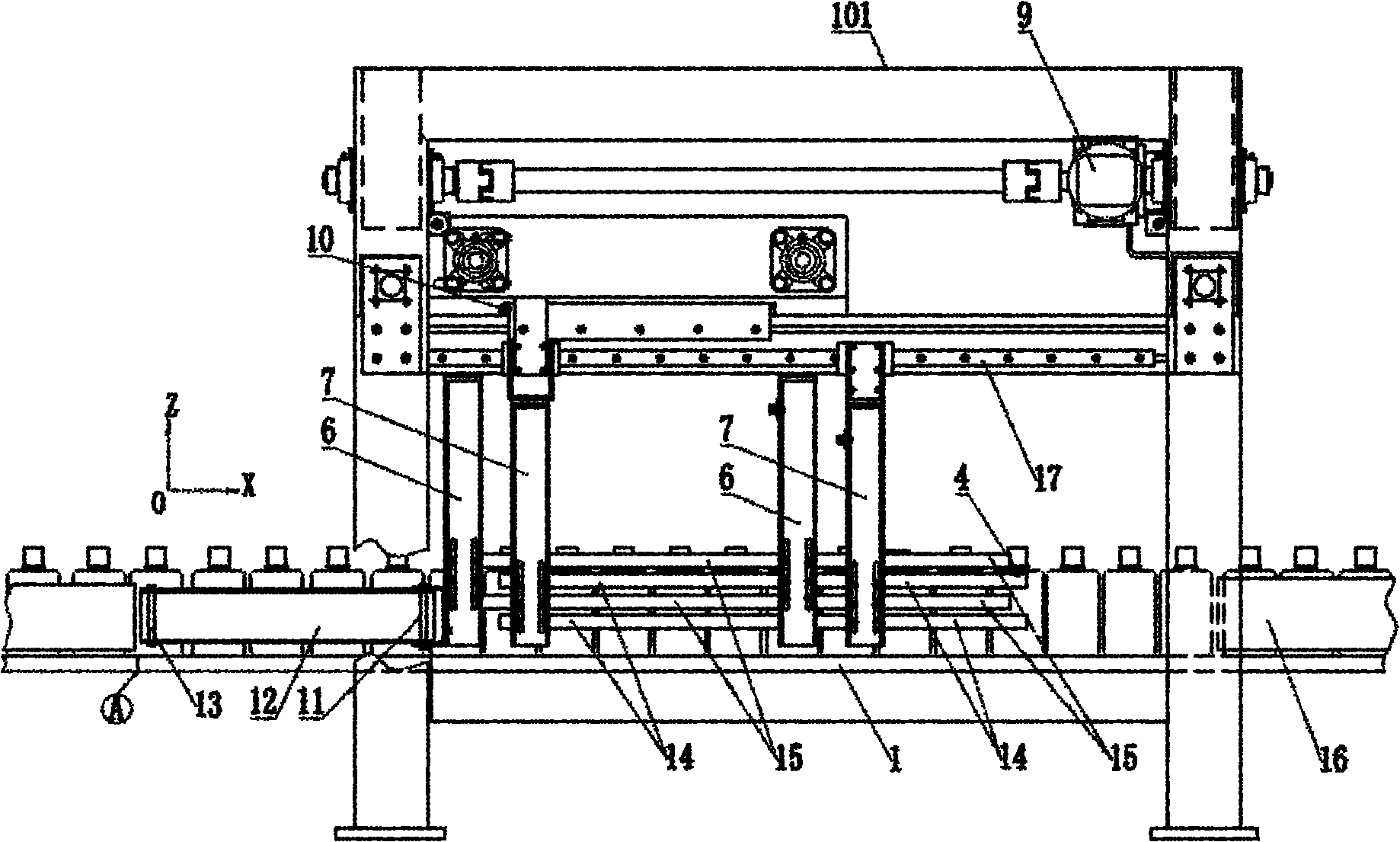

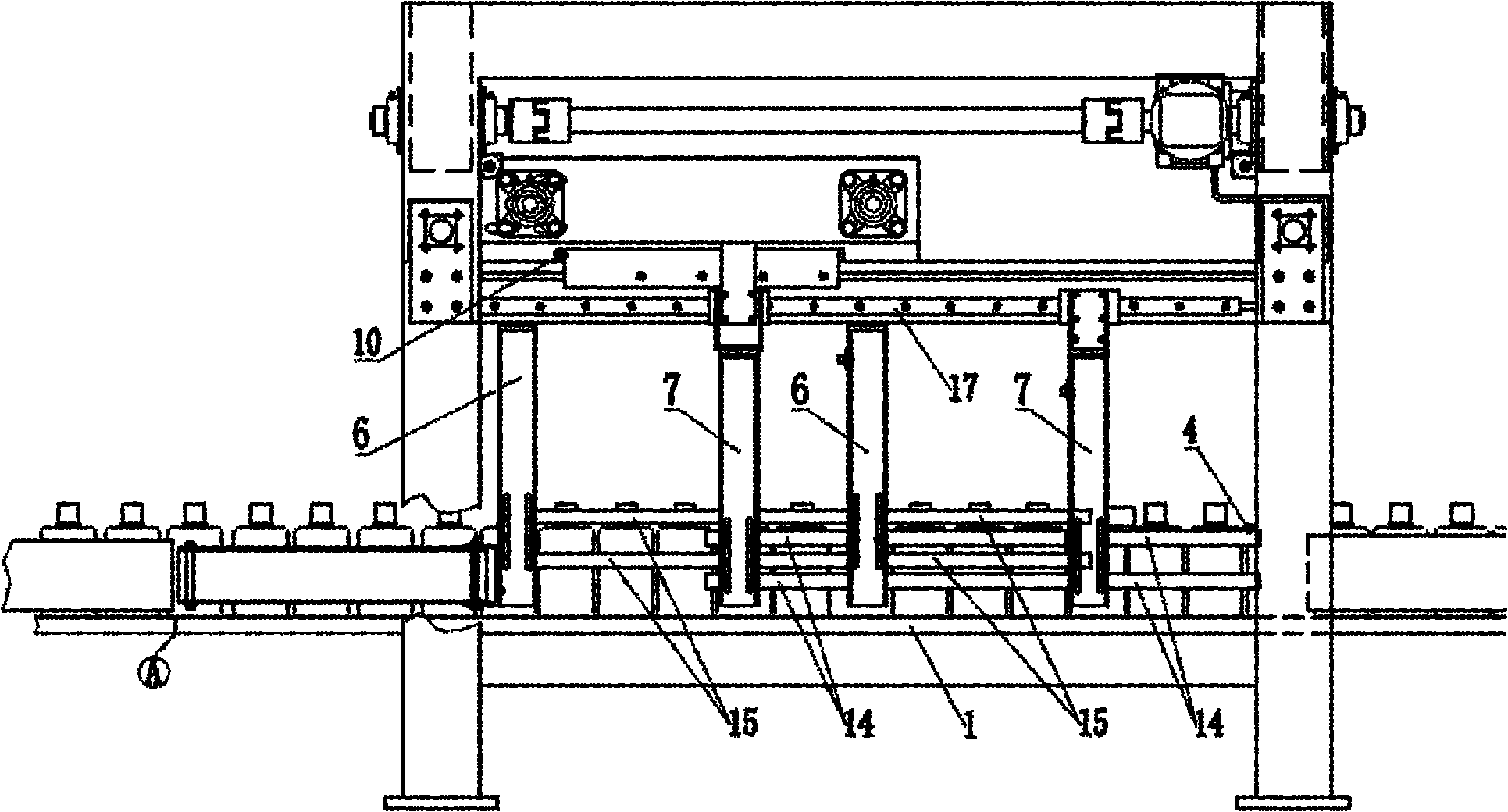

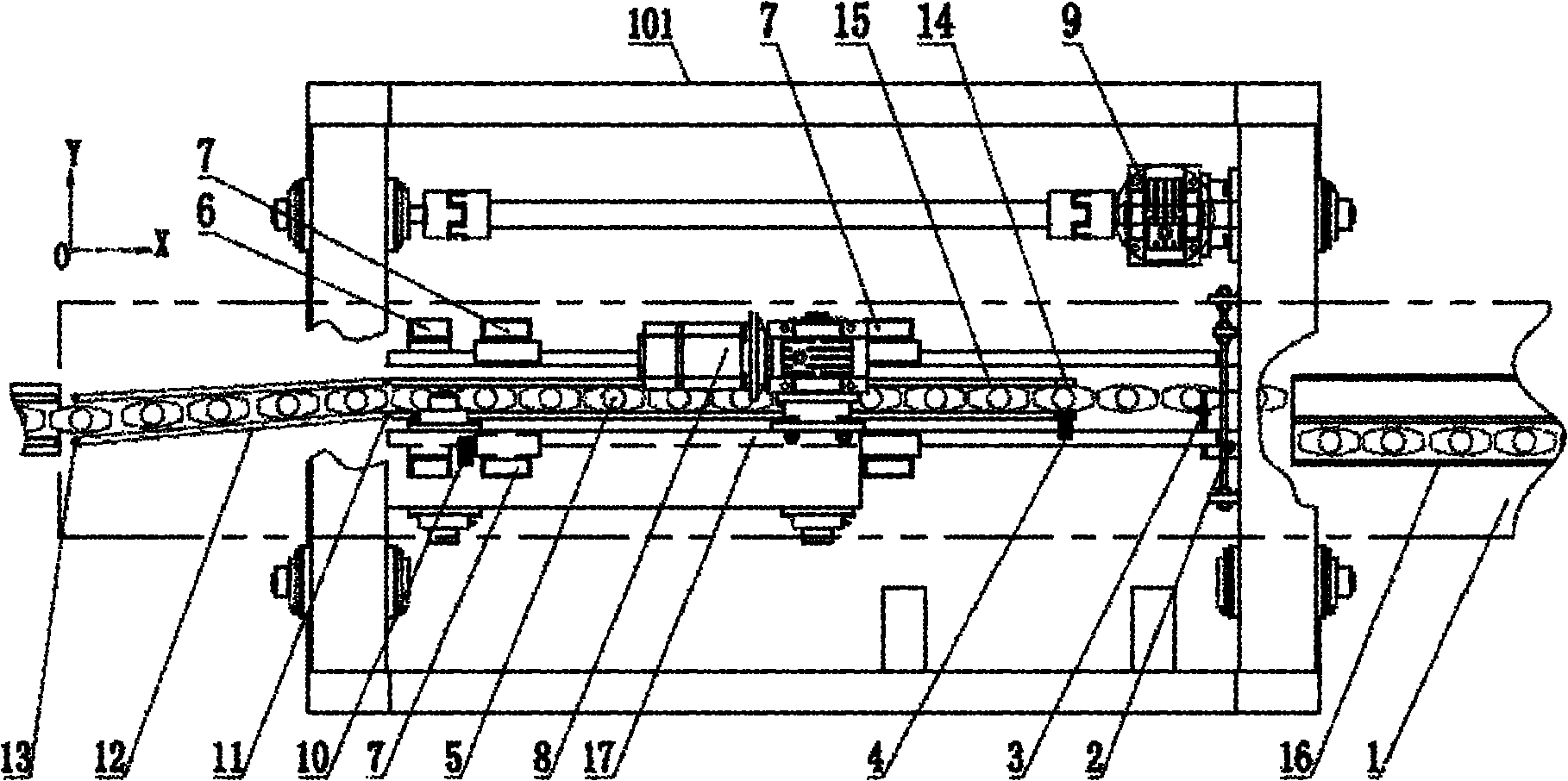

[0017] Markings in the attached drawings:

[0018] attached figure 1 , attached figure 2 In the middle, 1-multi-row bottle conveyor chain, 101-frame, 2-lane deceleration detection device, 3-lane origin detection device, 4-counting sensor, 6-fixed barrier frame, 7-telescopic frame, 8-servo bottle unscrambling motor, 9-servo lane separation motor, 10-bottle unscrambling origin detection device, 11-swing hinge, 12-swing guardrail, 13-hinge, 14-telescopic guardrail, 15-fixed guardrail, 16-multi-row Output guardrail, 17-rail.

[0019] attached figure 2 Middle, 5-single-row bottles.

[0020] Below in conjunction with attached pair of invention embodiment is described further:

[0021] Refer to attached figure 1 , attached image 3 , let the positive direction of the X-axis be the forward movement direction of the bottle, the positive direction of the Y-axis be the horizontal upper side, and the positive direction of the Z-axis be the vertical upward direction.

[0022] att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com