Method for assembling railway passenger car modular floors

A technology of railway passenger car and installation method, which is applied in the direction of railway car body, railway car body parts, transportation and packaging, etc., which can solve the problems of large number of wooden beams and plywood, increased labor intensity of workers, chaotic production environment, etc., and achieve high product quality. Quality, good heat preservation effect, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

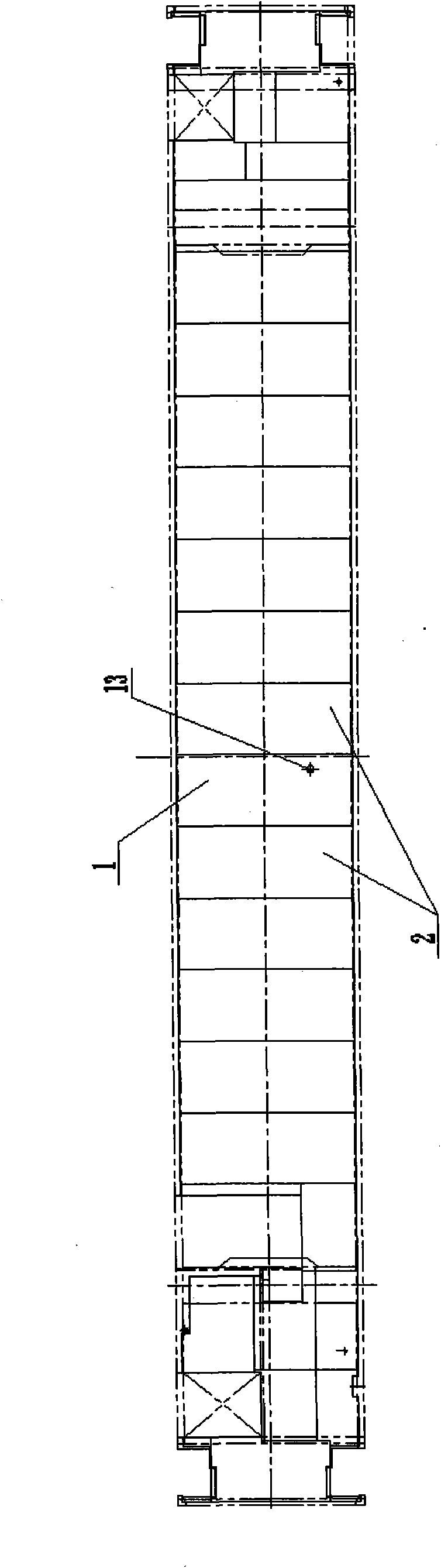

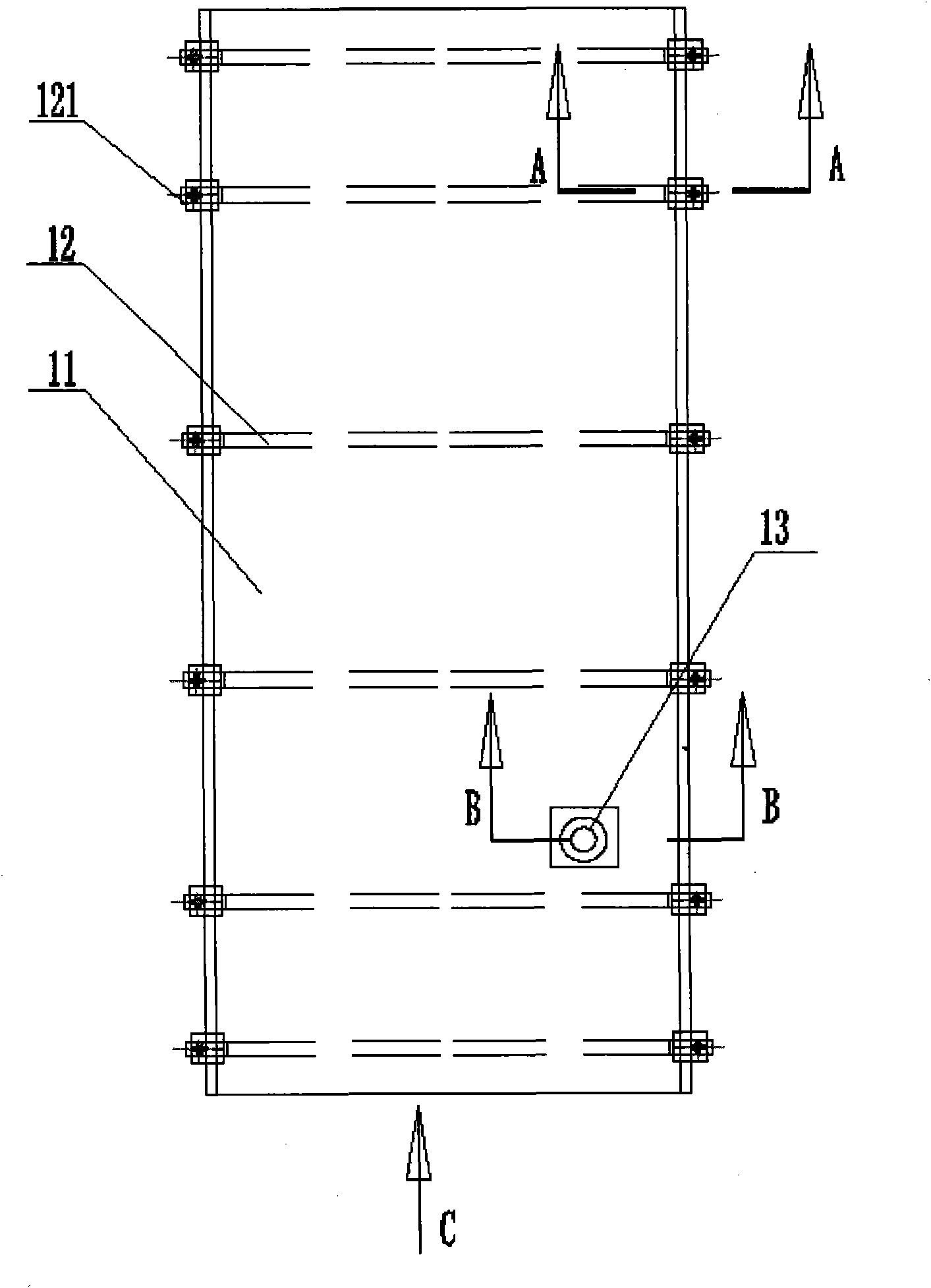

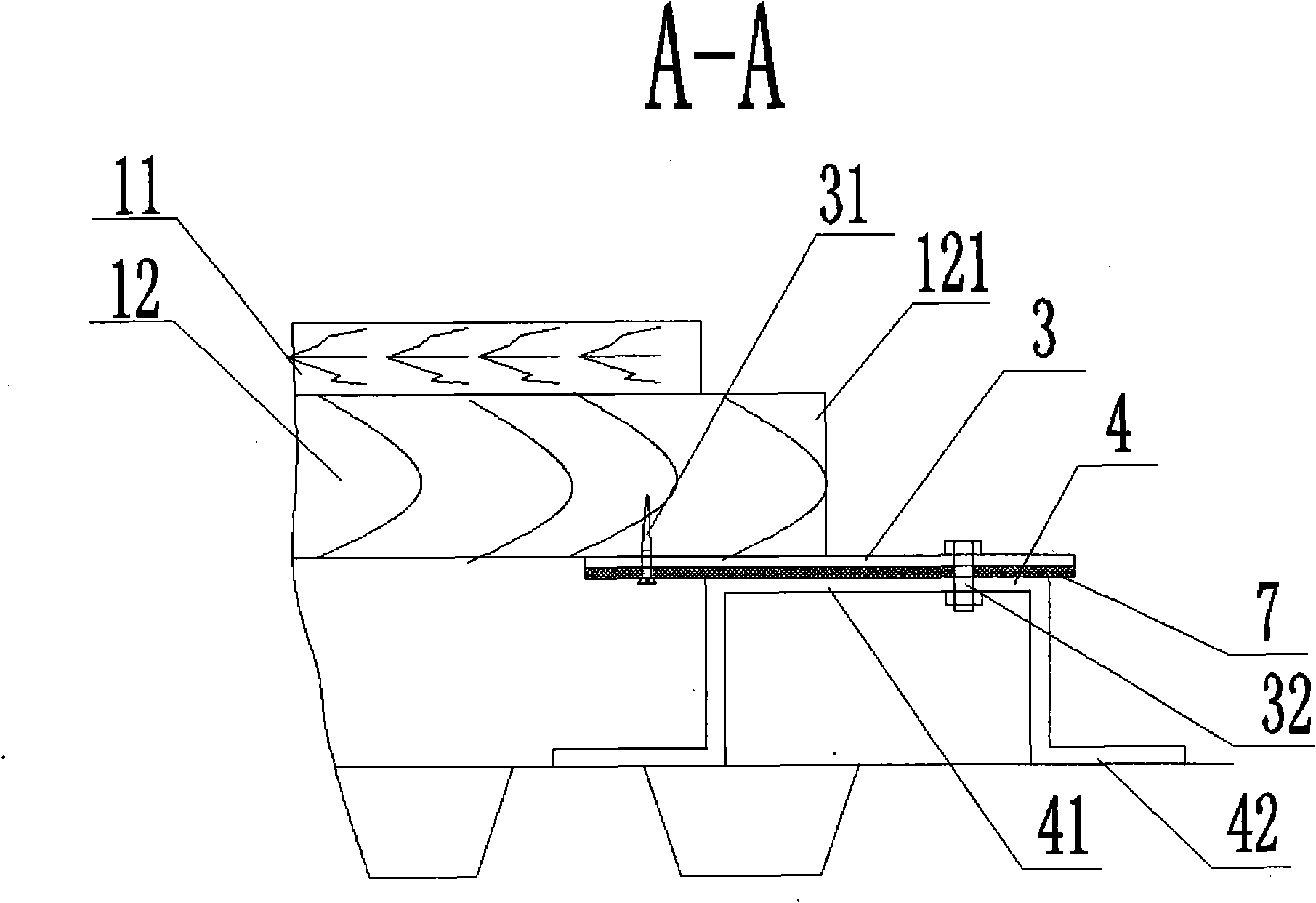

[0038] The railway passenger car modularized floor installation method of the present embodiment, such as Figure 1-8 shown, including the following steps:

[0039] a. Assembling the floor reference module 1 outside the passenger car: fix some reference beams 12 whose length is greater than the width of the reference rectangular plate 11 on the back of the reference rectangular plate 11, and make the two ends of the reference beam 12 exceed the two sides of the reference rectangular plate 11 to form a reference The mounting seat 121 is to obtain the floor reference module 1; the polyvinyl chloride cold-proof material 8 is filled between the adjacent reference beams 12;

[0040] b. Assembling the floor interoperable module 2 outside the bus: fix several interoperable beams 22 on the back of the interoperable rectangular plate 21 according to the position of the reference beam 12 on the back of the reference rectangular plate 11, and make one end of the interoperable beam 22 exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com