Processing technology of two intersected cylinders

A processing technology and cylindrical technology, which is applied in the field of machining parts, can solve problems such as processing difficulties, and achieve the effect of high cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

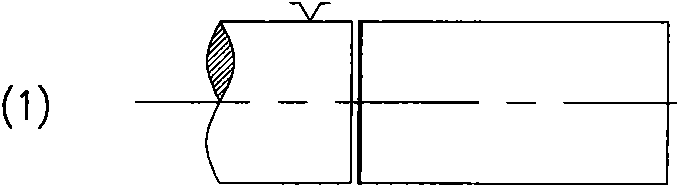

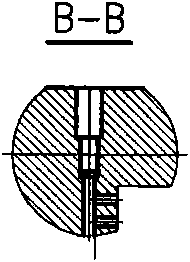

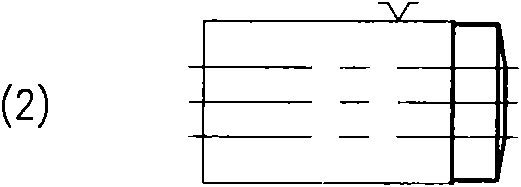

[0012] The telescopic cutter bar of the boring cutter used for turning the groove in the inner hole with a diameter of 120-130 mm is the part where two cylinders intersect. The process is as follows:

[0013] (1) Blank blanking of telescopic knife rod. According to the large end of the telescopic tool rod, that is, the diameter of the large cylinder plus the allowance for machining the outer circle, select the round steel of the corresponding size. The length of the blank is based on the small end of the telescopic tool rod, that is, the actual length in the axial direction of the small cylinder plus the length of the part that needs to drill the center hole. Saw off with a normal saw.

[0014] (2) Clamp the left end of the blank with a chuck on the lathe, drill the center hole at the right end of the blank and use the top to support it, and the outer circle of the right end of the car, the length of the outer circle of the car can meet the clamping of the chuck in the next ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com