Humidifying device

A humidification device and component technology, applied in air humidification systems, heating methods, lighting and heating equipment, etc., can solve the problems of increased water injection, inability to automatically change the amount of water in the humidification drum, complicated control, etc., and achieve simple control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

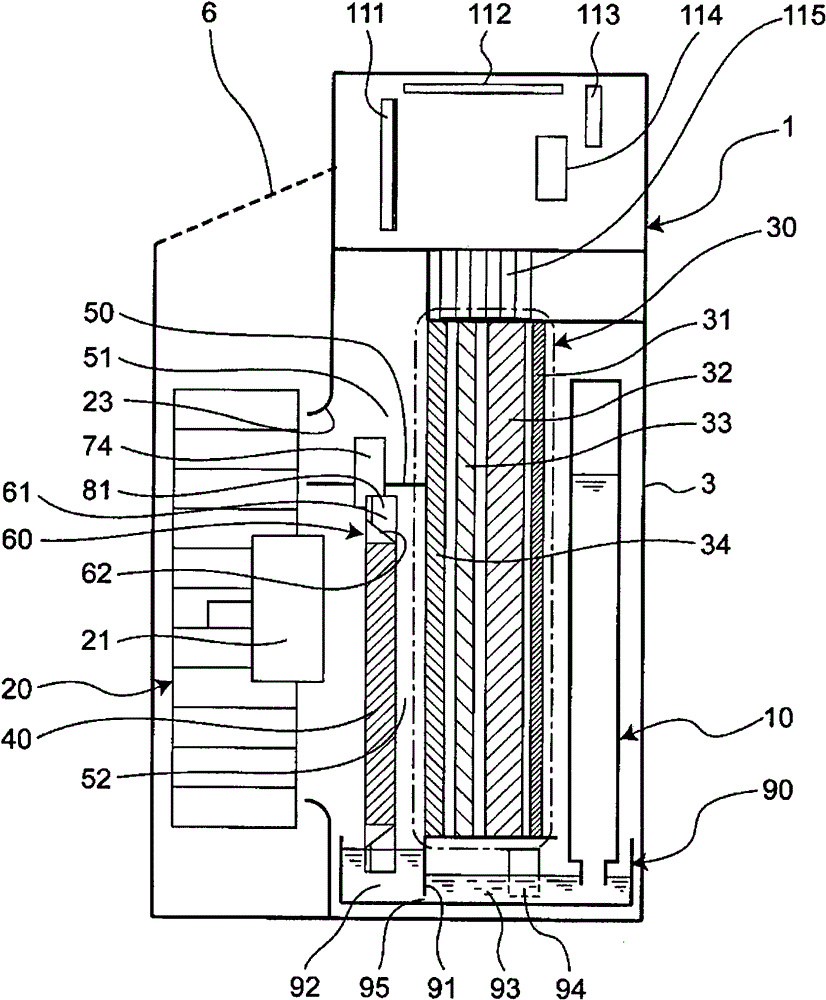

[0064] Hereinafter, the present invention will be described in detail based on the illustrated embodiment.

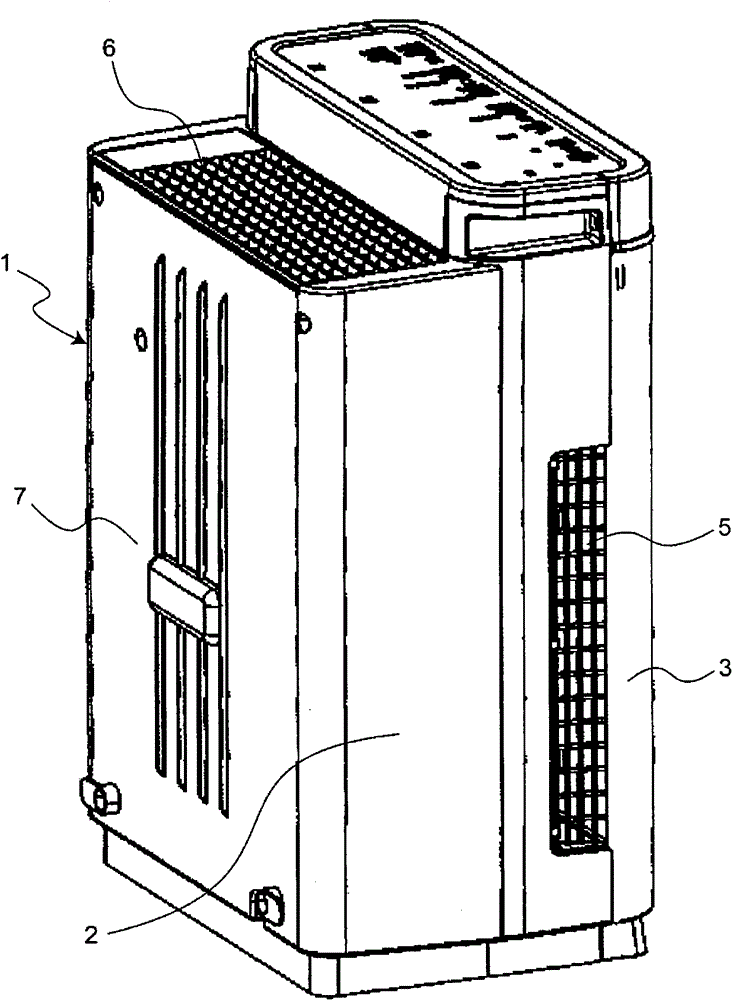

[0065] Such as figure 1 As shown, the humidification device includes a housing 1, and the housing 1 is composed of a housing main body 2 and a front surface panel 3 detachably mounted on the housing main body 2.

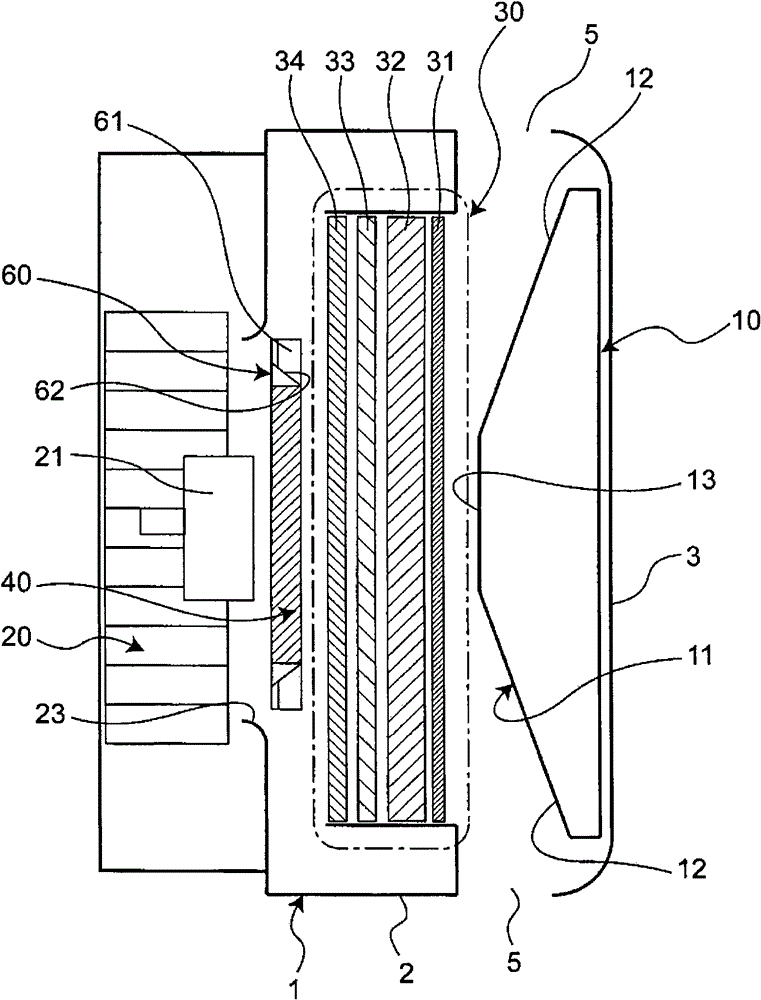

[0066] Suction ports 5 and 5 are provided on both sides of the housing 1 (refer to image 3 ), a blow-out port 6 is provided at the rear of the upper surface of the casing 1.

[0067] In this way, in this humidifier, the suction ports 5 and 5 are provided on the side surface of the housing 1, and the blower outlet 6 is provided on the upper surface of the housing 1, and the rear surface 7 of the housing 1 has no suction port and blower outlet. Therefore, the rear surface 7 of the housing 1 of the humidifier can be in close contact with the wall surface of a room not shown, and the degree of freedom of installation of the humidifier is high.

[0068] In the conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com