Filter elements

A filter and filter element technology, which is applied in the field of DOC catalyst carrier to manufacture this kind of filter element, can solve the problems of difficult control, loss of integrity, difficulty in maintaining high porosity, etc., and achieve low fuel consumption, low operating cost, and ventilation sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

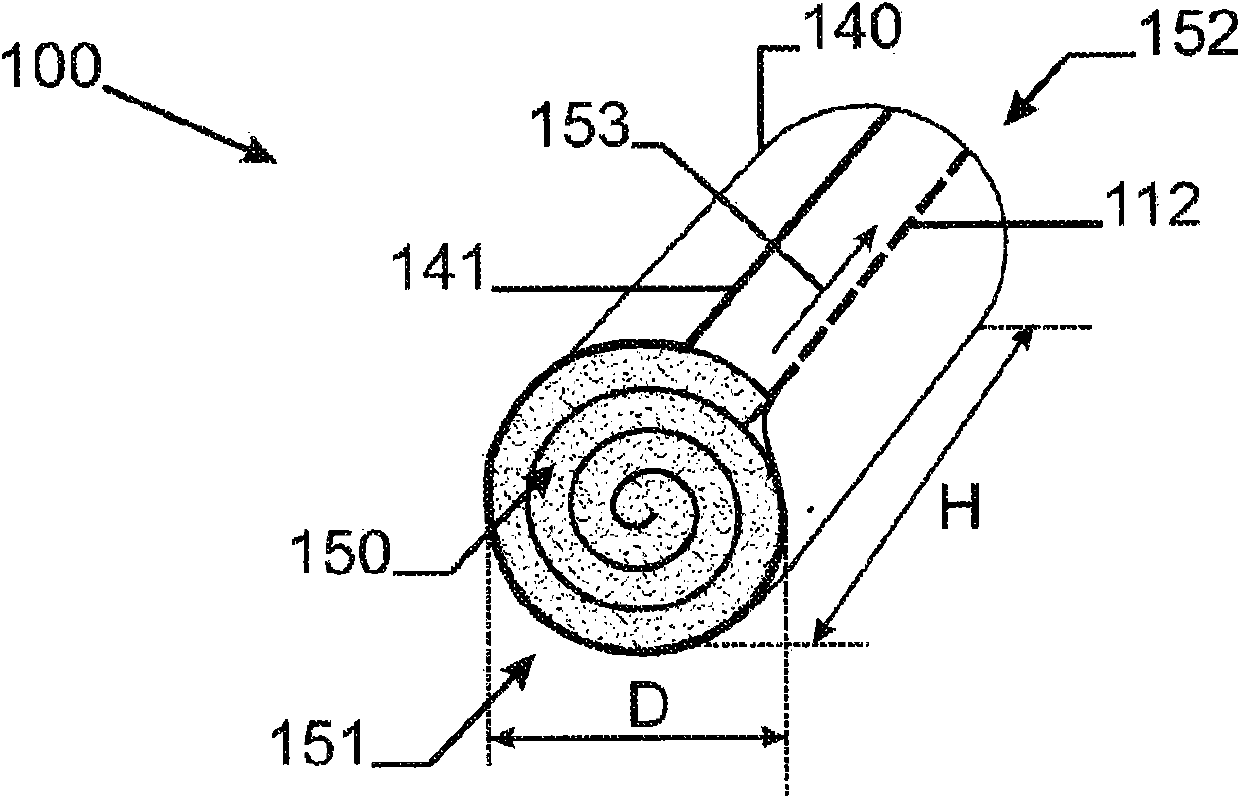

Image

Examples

Embodiment Construction

[0081] The present invention will be described with respect to specific embodiments and with reference to certain drawings but the invention is not limited thereto but only by the claims. The drawings are only schematic and not limiting. In the drawings, the size of some of the elements may be exaggerated and not drawn on scale for illustrative purposes. These dimensions and relative dimensions do not correspond to reality when the invention is implemented in practice.

[0082] In addition, the terms "first", "second" and "third" and the like in the specification and claims are used to distinguish similar elements and do not necessarily describe temporal or spatial hierarchical order or any other the order of the methods. It is to be understood that the terms so used are interchangeable under appropriate circumstances and that the described embodiments of the invention are capable of operation in other sequences than described or illustrated herein.

[0083] Furthermore, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com