Automatic assembly method and assembly system for strain gauge

An automatic assembly, strain gauge technology, applied in metal processing, manipulators, metal processing equipment and other directions, can solve the problem of not considering whether the strain gauge will deflect, drift, whether the size is consistent, etc., to achieve good assembly accuracy, The effect of improving accuracy and consistency, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

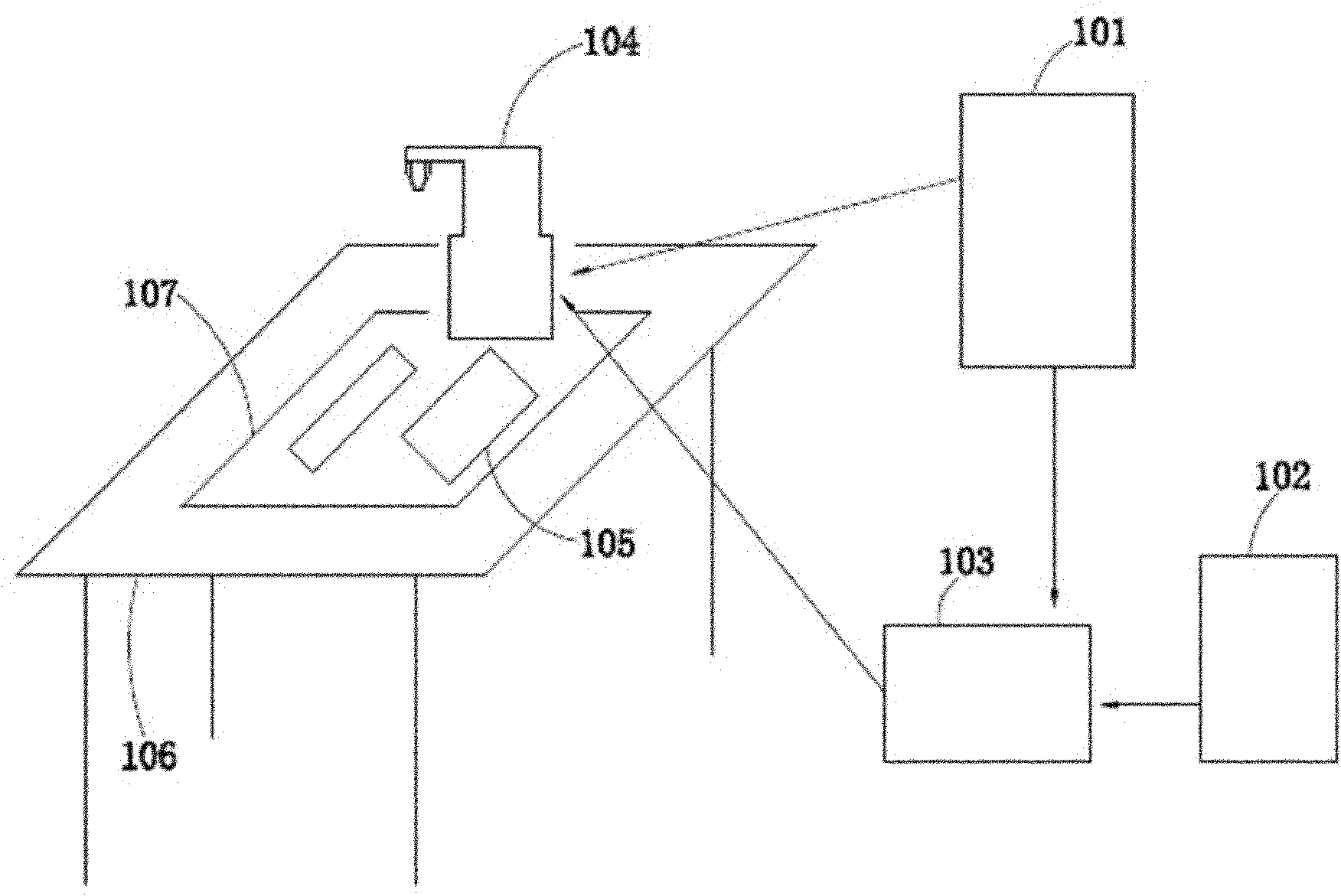

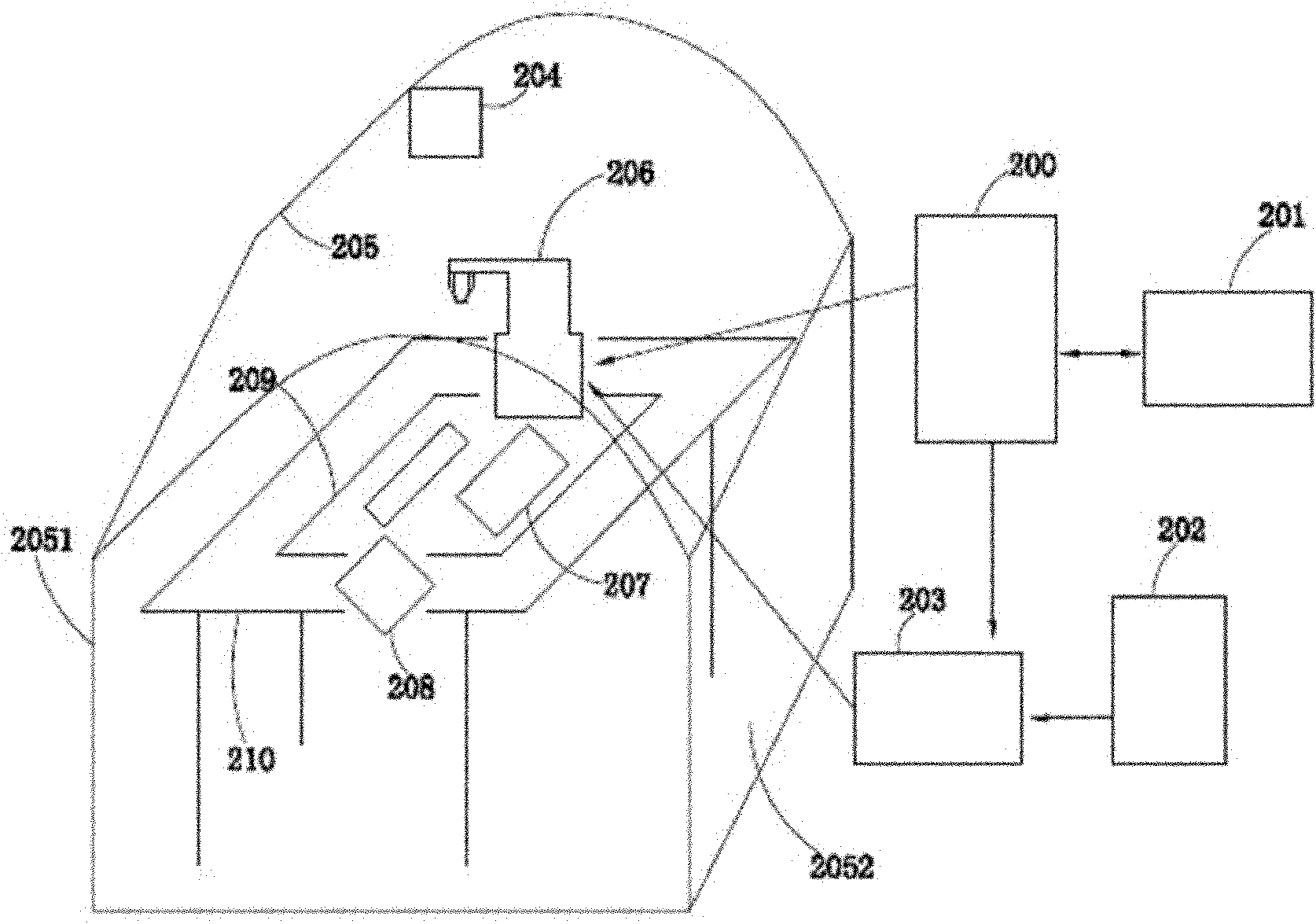

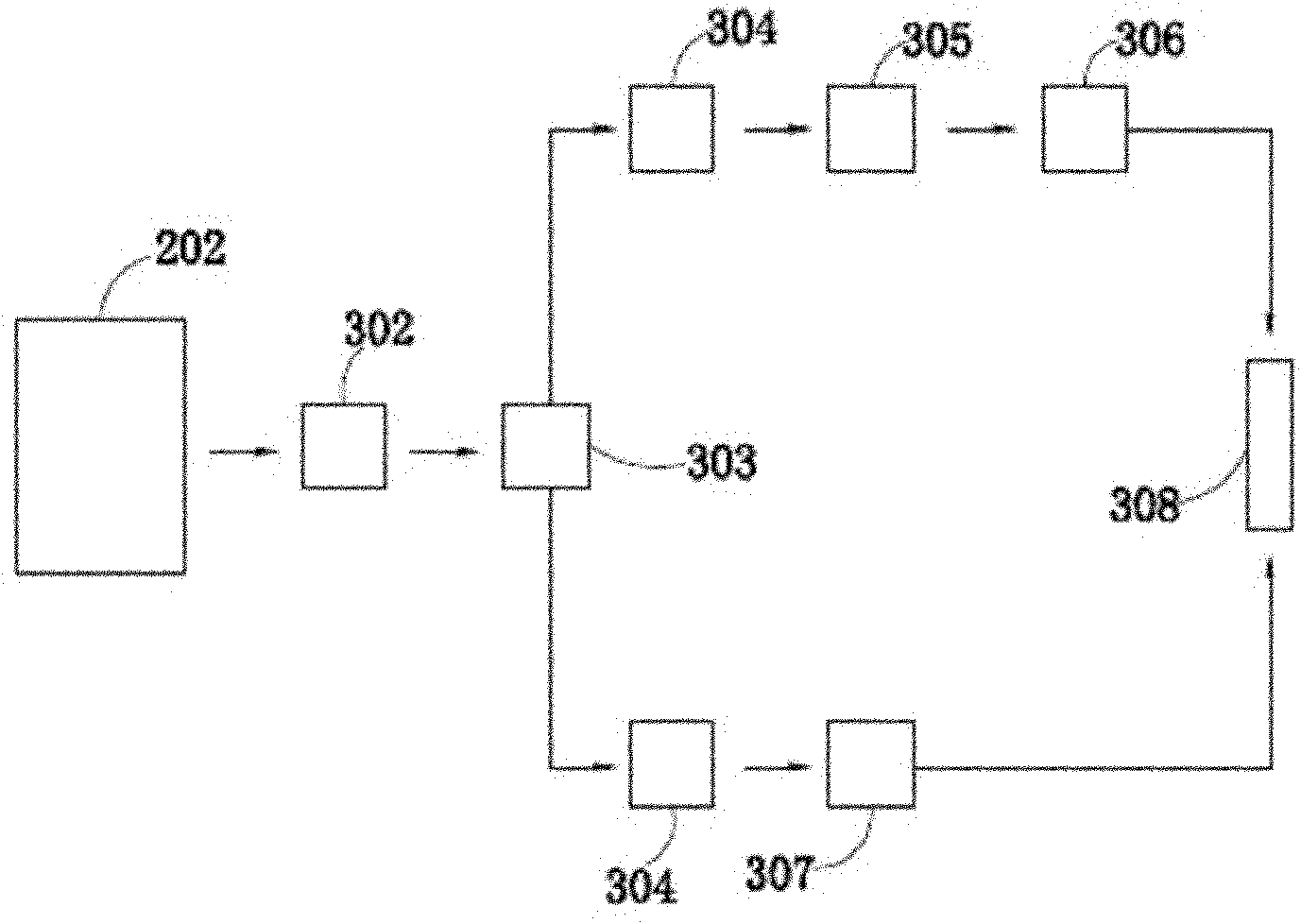

[0030] Such as figure 2 , Figure 7As shown, the method for automatic assembly of strain gauges provided in this embodiment includes the use of industrial computer 201 to control the mechanical arm 206 to automatically assemble the strain gauges. The precise positioning of the suction and placement of the strain gauges is to use the centering camera 208 and the bottom-finding camera 204 to collect images of the suction and placement positions of the strain gauges, and calculate the central position of the strain gauges through the image information of the centering camera 208, Deflection angle and offset; at the same time, according to the elastic body 209 image information provided by the bottom-finding camera 204 to place the strain gauge, calculate the elastic body 209 model, direction and center position of the assembly hole; after obtaining these information, pass the information through the communication channel Transmission to the robotic arm control cabinet 200, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com