High-thrust permanent magnet direct drive linear electric motor

A permanent magnet direct drive, linear motor technology, applied in the field of direct drive permanent magnet motors and high-thrust permanent magnet linear motors, can solve the problems of difficult motor manufacturing and installation, large number of primary and secondary pole pairs, and low running speed. , to achieve the effect of high mechanical strength, reducing manufacturing difficulty and cost, and improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

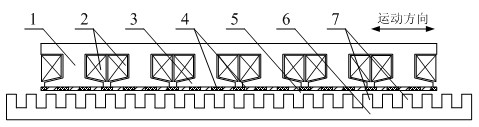

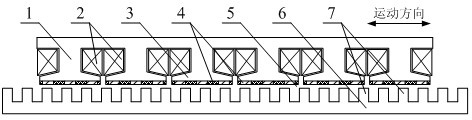

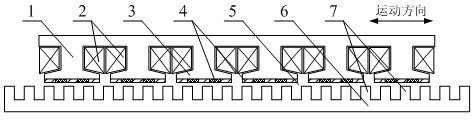

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The high-thrust permanent magnet direct-drive direct-drive motor provided by the present invention is suitable for low-speed and high-thrust working conditions, and can be used as a direct-drive motor to run in the electric or power generation state. Its structure includes a motor primary and a motor secondary. The primary iron core, armature winding, primary pole shoe and permanent magnet of the slot, the armature winding is embedded in the primary iron core wire slot, and the permanent magnet is installed on the surface of the primary pole shoe; the secondary of the motor includes the secondary iron core and the secondary salient pole; in the motor An air gap is provided between the primary permanent magnet and the secondary salient pole.

[0022] Both the primary iron core and the secondary iron core are made of silicon steel laminations or other magnetically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com