Construction method for split burying of large T-shaped sleeve bolt

A construction method and bolt technology, which is applied in the direction of basic structure engineering, architecture, building construction, etc., can solve the problems of restrictions and high installation costs, and achieve the effects of reducing types and quantities, reducing material consumption, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] Referring to the accompanying drawings, the large-scale T-shaped sleeve bolt split burial construction method described in this embodiment is carried out as follows:

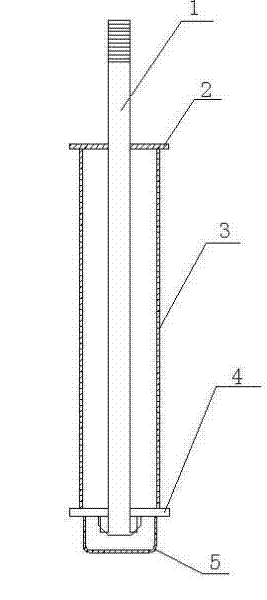

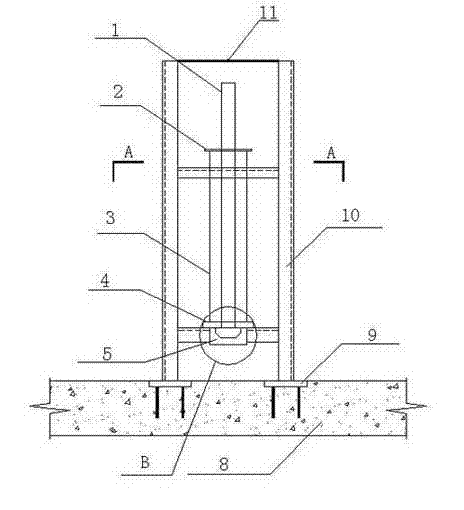

[0021] a. Embed four embedded iron pieces 9 of 100×100×6mm on the concrete cushion 8 according to the four corners of the square, and install a bolt fixing frame 10 above the embedded iron pieces 9. The bolt fixing frame 10 is a frame type, composed of Angle steel welded (see image 3 , Figure 4 ).

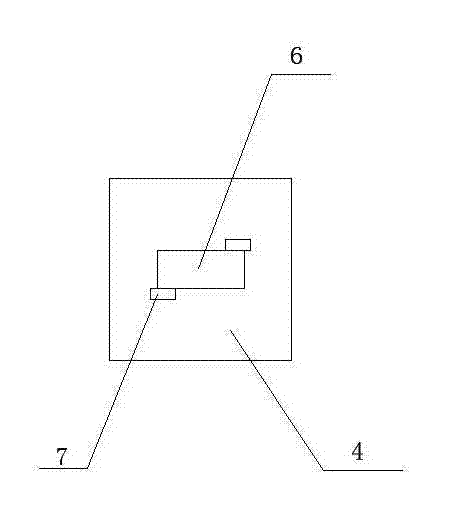

[0022] b. Use the total station to measure the control point 11 of the bolt center (see image 3 ), and the second person conforms to the position of the center point. After confirming that the point is correct, the anchor plate 4 is welded on the bolt fixing frame 10. The anchor plate 4 is made of steel plate, and its center is provided with a rectangular hole 6. The hole The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com