Hydraulic supporting, leveling and clamping device of large-size working piece

A clamping device, a technology for large workpieces, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve the problems of unusable production lines, high equipment cost, complex and huge structure, etc., to improve production efficiency and save money. The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The processing object is the CRTS Ⅱ Borg ballastless track slab used in the construction of high-speed railway with a speed of 350 kilometers per hour. Workpiece appearance length × width × height dimensions: 6450 × 2550 × 200 (mm), weighing 9 tons. The material is special concrete.

[0033] The invention can also be used for supporting, leveling and clamping installation of other large heavy-duty boards and box-type components.

[0034] The working process and principle of workpiece 10 movement, leveling and clamping:

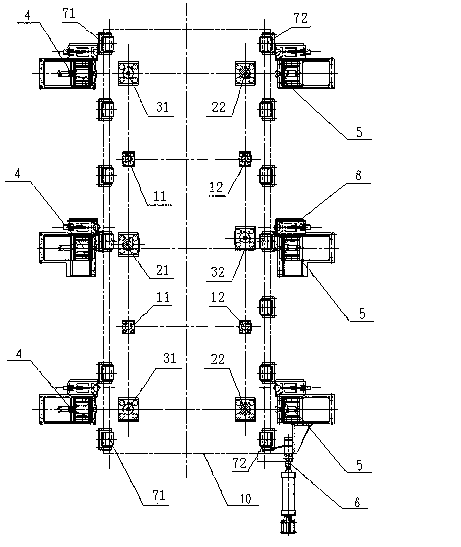

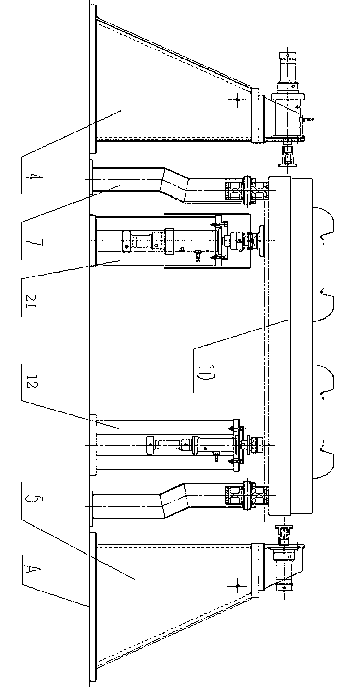

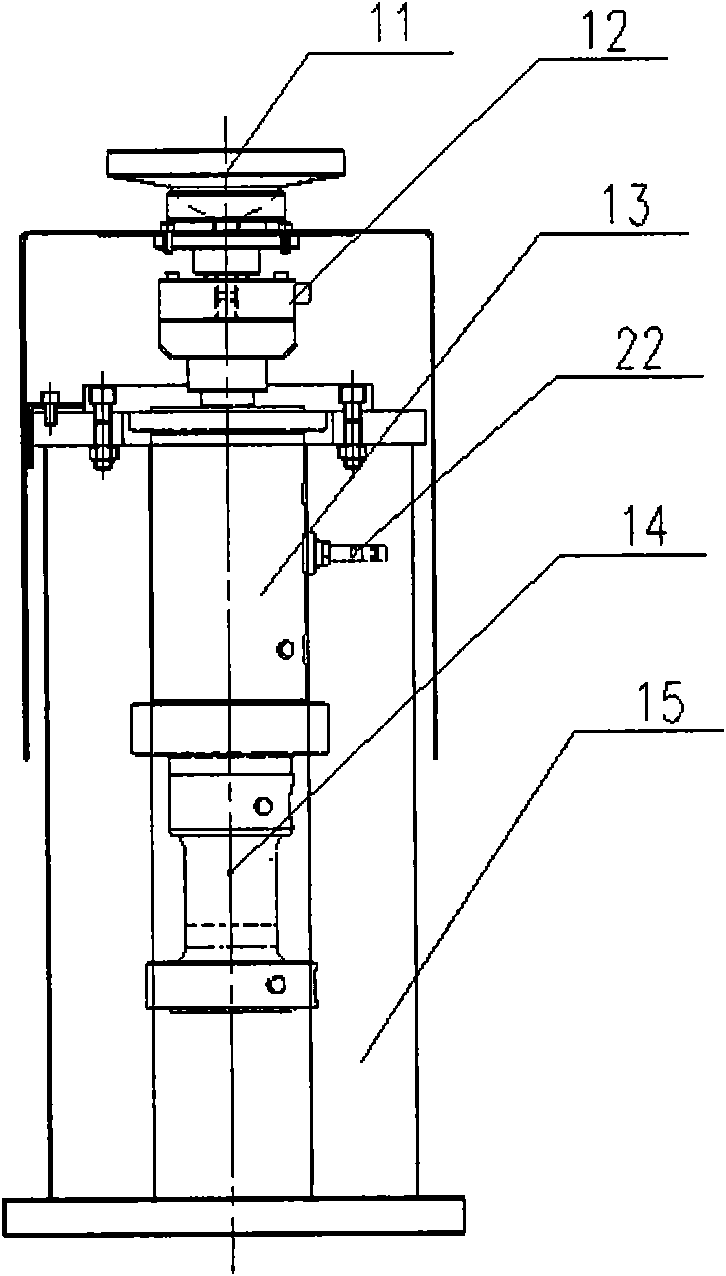

[0035] Such as figure 1 , 2 , 3, and 4, the workpiece 10 is sent to the processing position from the previous station by the transmission support roller assembly one, two 7-1, 7-2 through the guide of the roller guide mechanism 8, and the longitudinal positioning mechanism 6 pairs the workpiece 10 for vertical orientation. Under the control of the control system, the three jacking cylinder assemblies 1, 2 2-1, 2-2 and the three pressure regulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com