Special machine for welding pipeline with small pipe diameter

A special-purpose machine and small-diameter technology, applied in welding equipment, welding accessories, arc welding equipment, etc., to achieve a high degree of automation, ensure welding quality, and accurate and stable wire feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

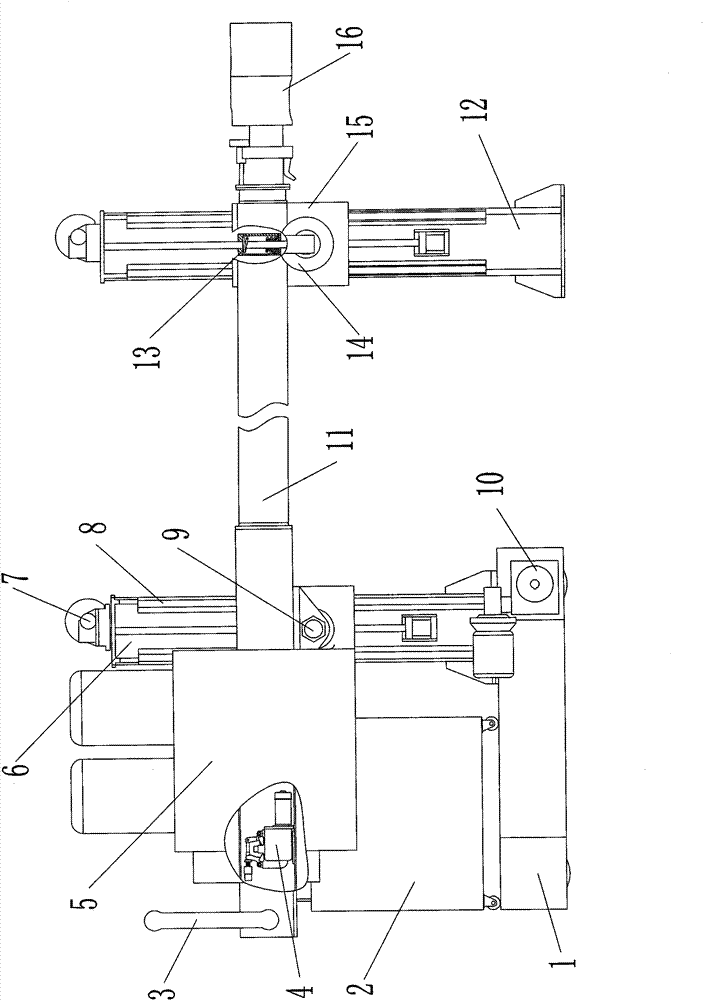

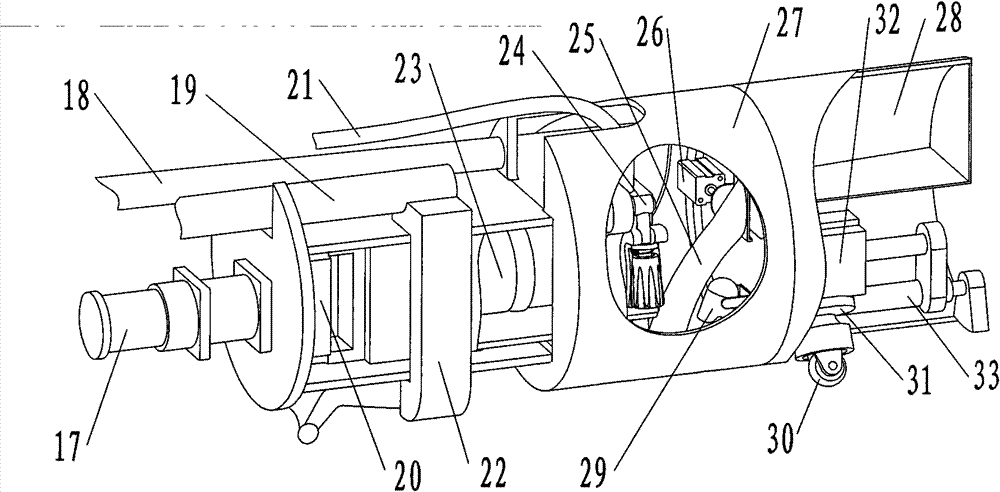

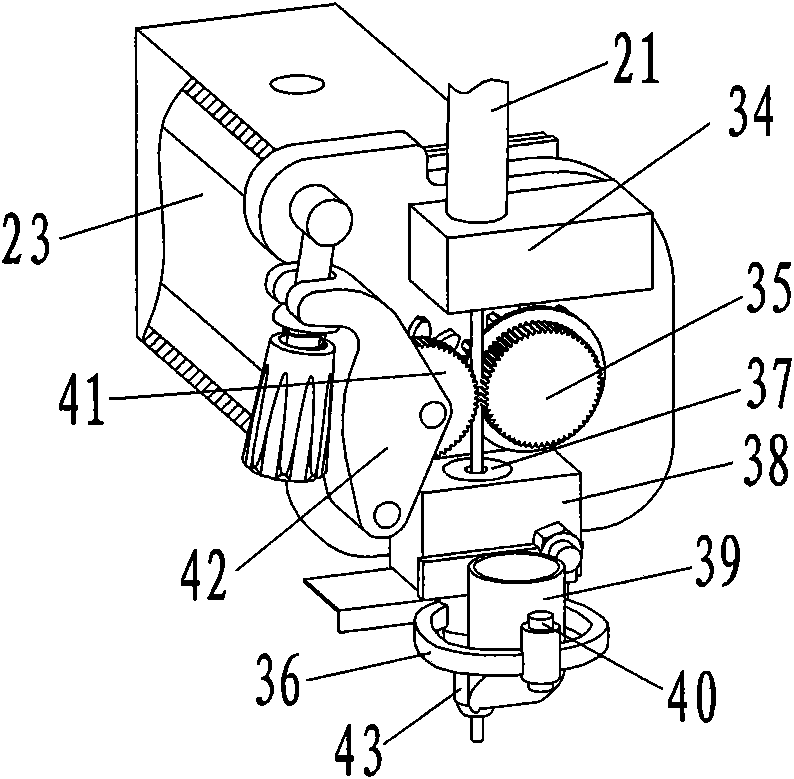

[0018] The structure of the present invention is as figure 1 As shown, the small-diameter pipe welding special machine includes a walking trolley 1, a welding power source 2, a cross arm 11, a moving column 6, a fixed column 12, a welding head 16, a flux conveying and recycling device 5, an automatic welding seam tracking device and Programmable Controllers. Welding power supply 2 and mobile column 6 are all installed on the walking trolley 1. Walking trolley 1 comprises car body, motor, speed reducer 10 and road wheel, and motor and speed reducer 10 are installed on the car body side, and the input end of speed reducer 10 is connected with motor, and road wheel is installed on the output end. Speed reducer 10 adopts worm gear reducer. Walking trolley 1 is used for realizing automatic welding, runs on track, is with the welding torch in the welding machine head 16 (referring to image 3 ) to move linearly along the pipe wall to realize the automatic welding of the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com