Method for producing digital model applied to dental implant and method for producing artificial teeth

A production method and technology of digital models, applied in the fields of dental prosthesis, electrical digital data processing, special data processing applications, etc., can solve problems such as inability to apply patients' dentures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

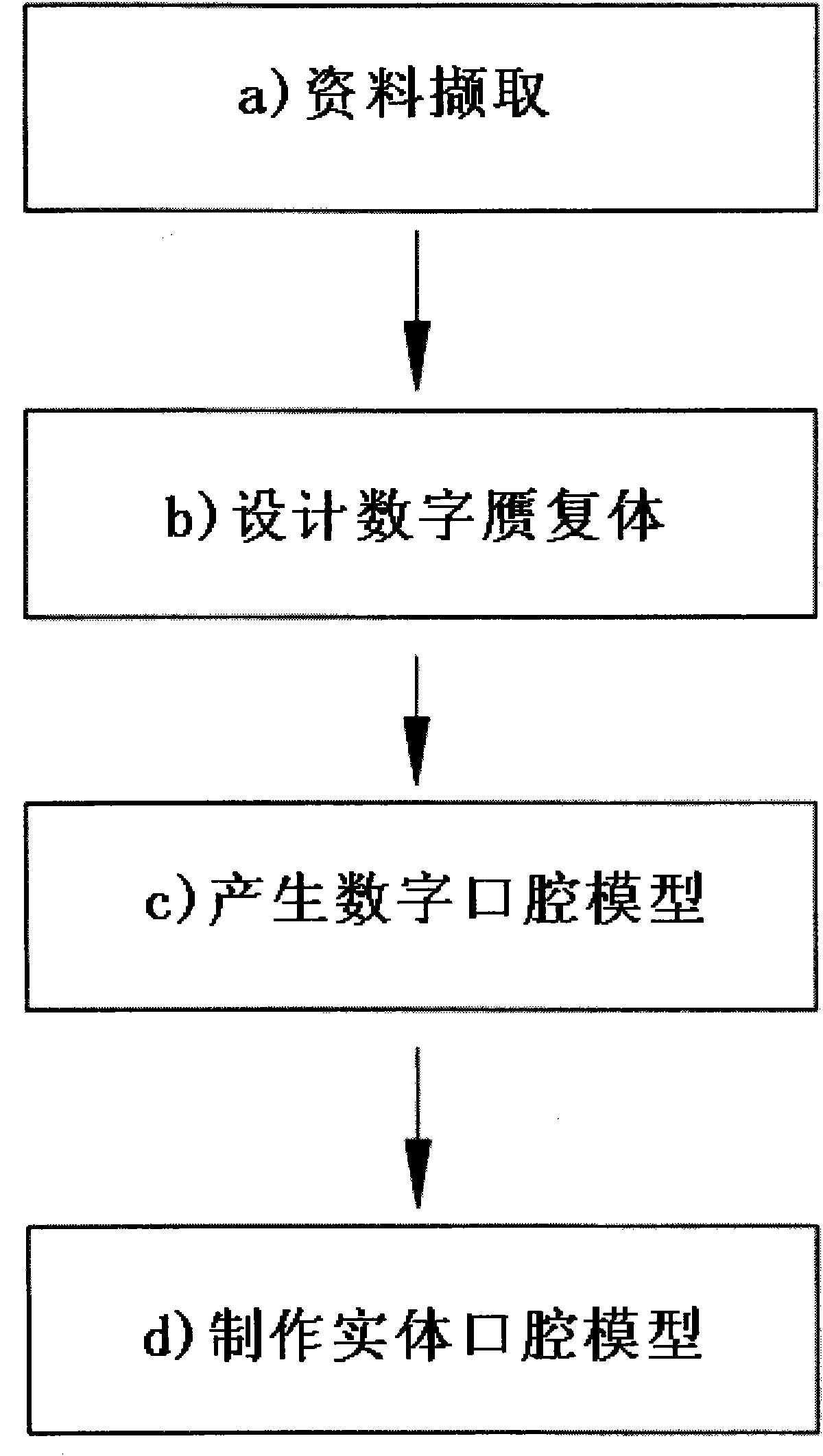

[0078] Such as figure 1 As shown, a method for making a digital model applied to artificial dental implants provided by the present invention mainly includes the following steps:

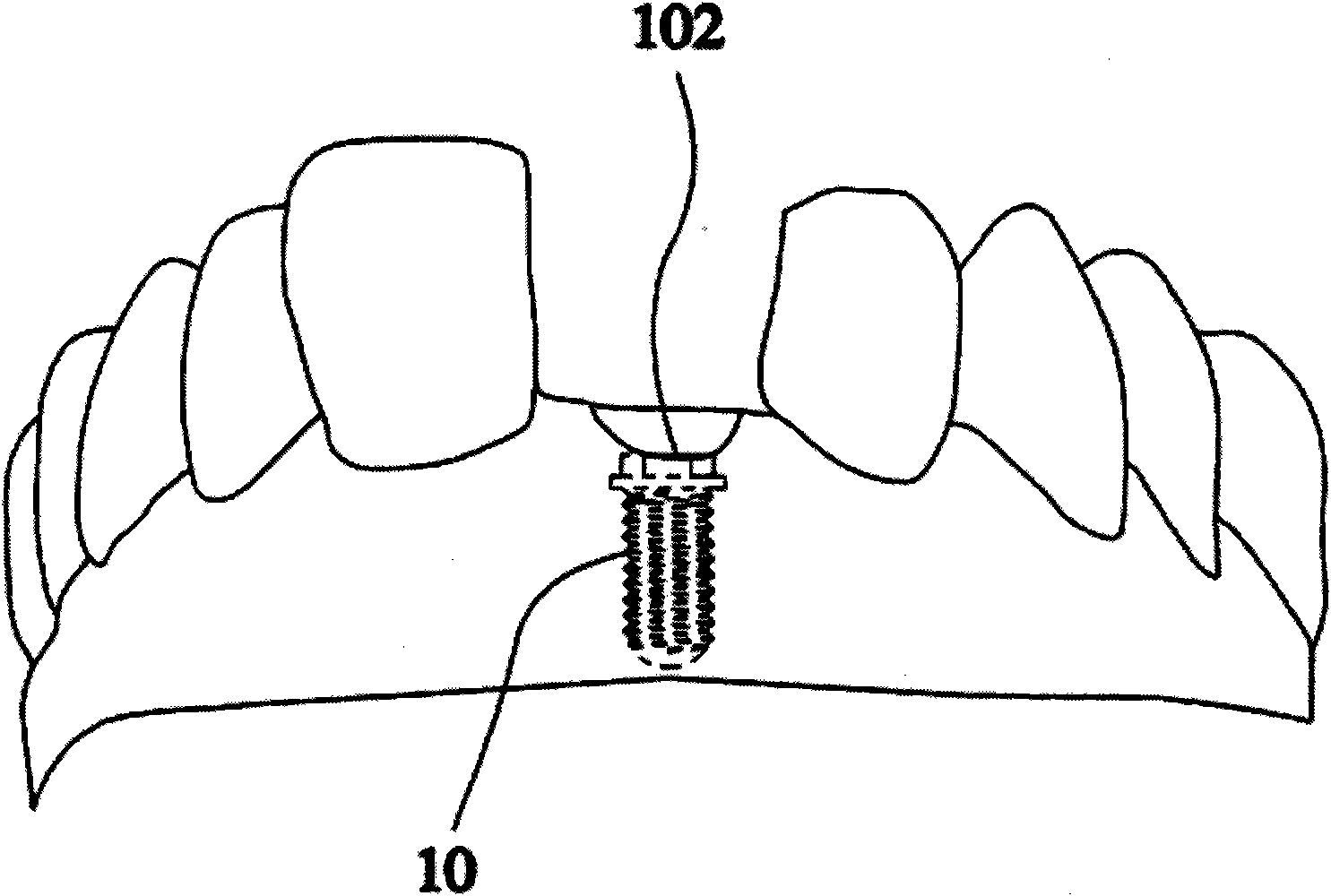

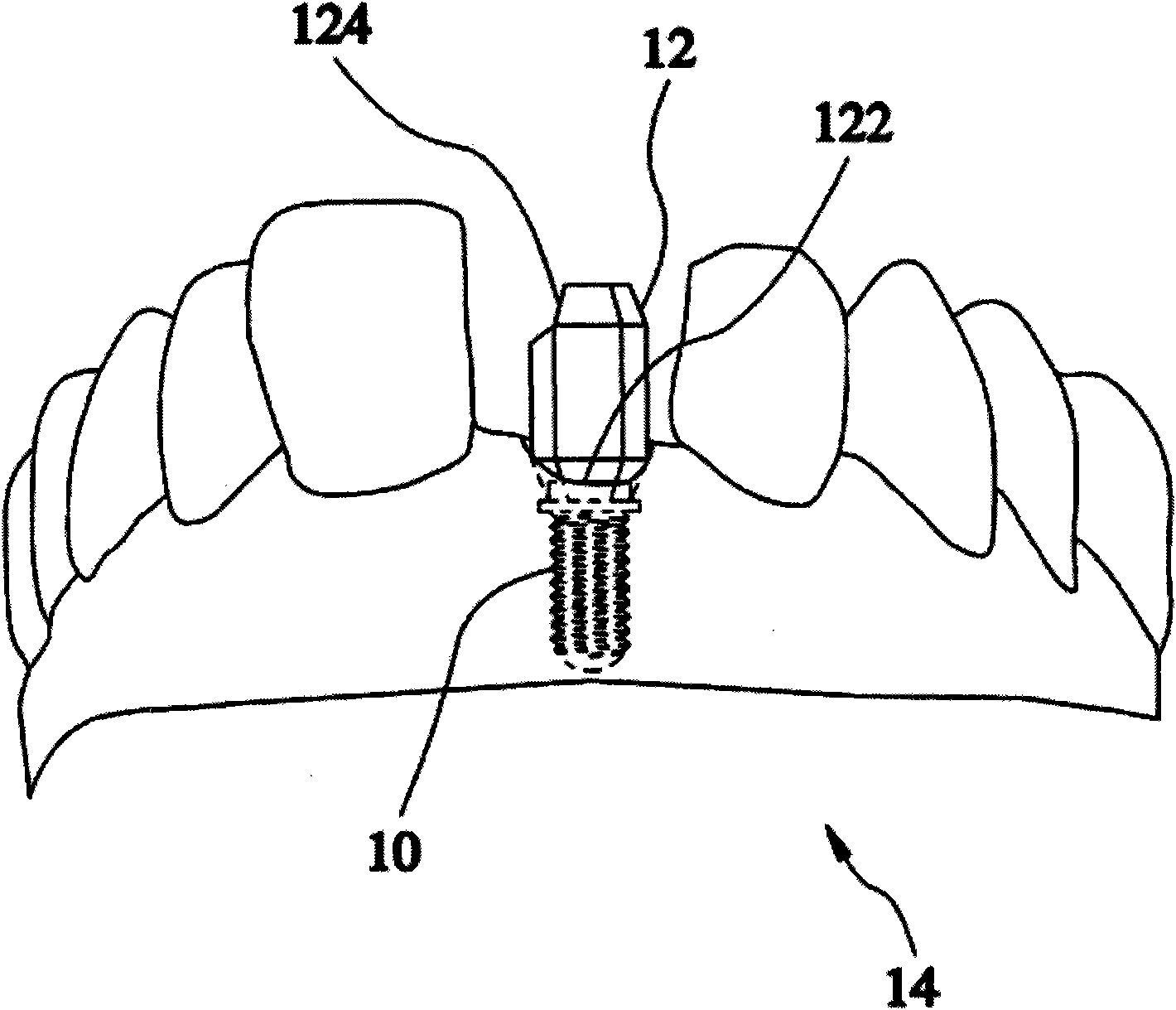

[0079] a) Data retrieval: if Figure 2 ~ Figure 4 As shown, under the condition that a patient has an implant 10 (fixture) in the oral cavity, a jig 12 is selected, the top of the jig 10 has a connection interface 102, and the bottom of the jig 12 has a corresponding connection interface. Docking interface 122, and the jig 12 has a jig feature point 124, the jig feature point 124 is exposed on the gingiva in the patient's oral cavity and outside the implant 10, and the docking interface 122 is joined with the connection interface 102, so that The jig 12 is combined with the implant 10 . Use an intraoral scanner (not shown in the figure) to scan the patient's oral cavity to obtain a first oral digital data 14 and store it in the computer 16 . The first oral cavity digital data 14 includes digital ...

Embodiment 2

[0089] Such as Figure 12 Shown, a kind of manufacture method of denture provided by the present invention. The difference between this embodiment and Embodiment 1 is that this embodiment also includes step e) to complete the dentures after completing the work of making the digital model applied to the artificial tooth. This embodiment mainly includes the following steps:

[0090] a) Data retrieval: if Figure 2 ~ Figure 4 As shown, under the condition that a patient has an implant 10 (fixture) in the oral cavity, a fixture 12 is selected, the top of the implant 10 has a connection interface 102, and the bottom of the fixture 12 has a corresponding connection interface. Docking interface 122, and the jig 12 has a jig feature point 124, the jig feature point 124 is exposed on the gingiva in the patient's oral cavity and outside the implant 10, and the docking interface 122 is joined with the connecting interface 102, so that The jig 12 is combined with the implant 10 . Use ...

Embodiment 3

[0100] Such as Figure 14 As shown, a method for making a digital model applied to artificial dental implants provided by the present invention is roughly the same as in Example 1, except that:

[0101] Such as Figure 15 ~ Figure 16 As shown, step c) generates a digital oral model: separate the digital prosthesis 164 from the second oral digital data 18, so that the digital prosthesis 164 exposes the docking interface 122, while the second oral digital data 18 exposes the connection The interface 102 then uses the second oral digital data 18 to generate a second digital oral model (not shown in the figure) after processing.

[0102] Step d) Making a solid oral cavity model and a practical prosthesis: a second solid oral cavity model 30 is produced from the second digital oral cavity model, the second solid oral cavity model 30 has a connection interface 102, and the digital prosthetic body 164 is materialized into a second The practical prosthesis 32 , the second practical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com