Method for thermally compensating gaging device and thermally compensated gaging station

A metering device and heat compensation technology, which is applied in the direction of transmitting sensing components, instruments, etc. by fluid devices, can solve the problems that compensation cannot be achieved, and known methods cannot be applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

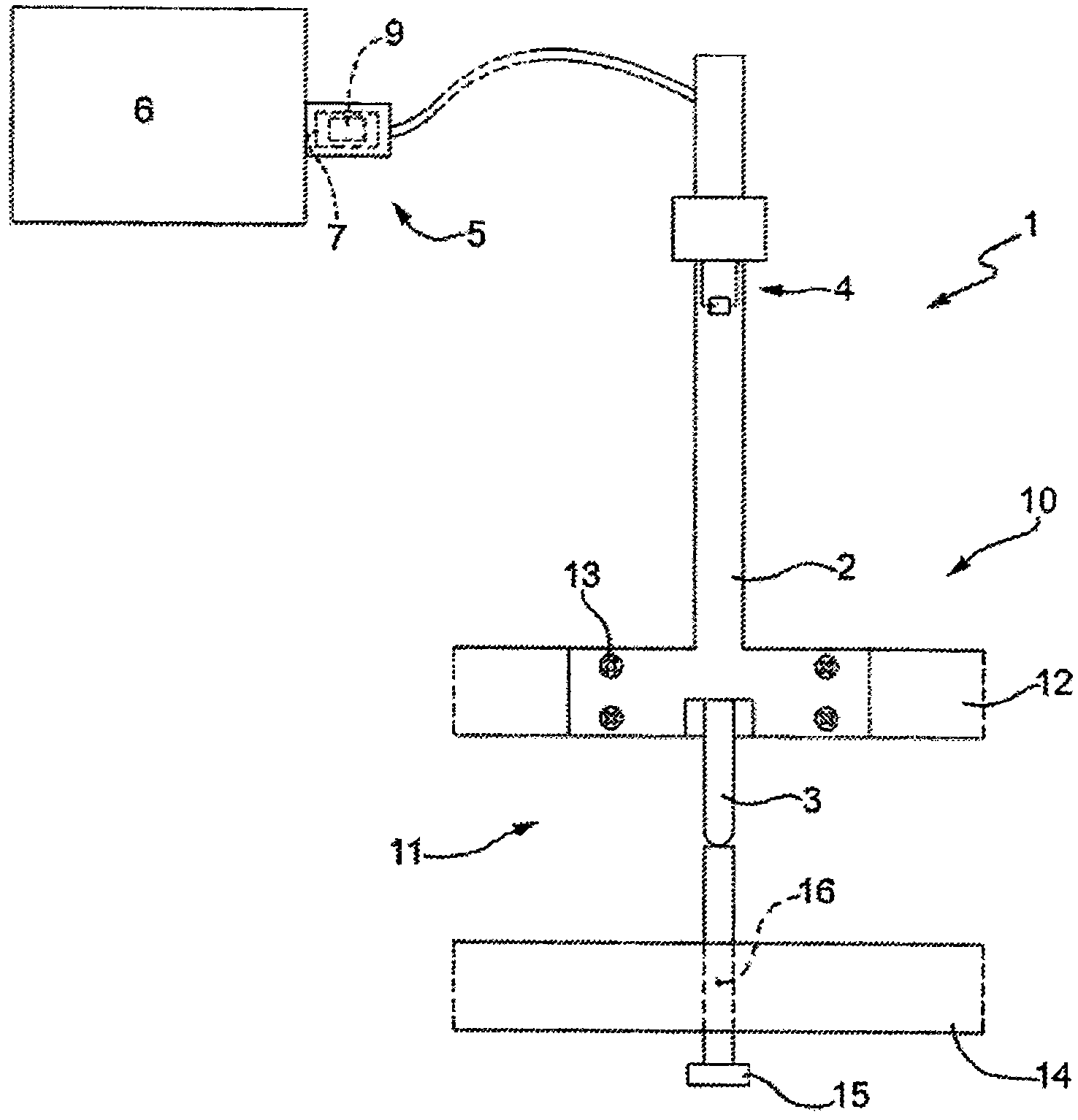

[0012] in figure 1 Here, the reference sign 1 generally indicates a metering device, such as a position sensor including a linear transducer of the LVDT (Linear Variable Differential Transformer) type, such as the same type as the position sensor described in US Pat. No. 6,931,749 B1. The metering device or position sensor 1 includes a fixed part 2 and a movable element, and the movable element is more specifically a slider 3 with a contact and movable relative to the fixed part. The transducer of the position sensor 1 includes a winding and a movable iron core (which are known per se and are therefore not shown in the drawings) respectively connected to the fixed part 2 and to the movable element or slider 3, and is suitable for providing An alternating current signal, which has a variable intensity voltage and depends on the position of the movable slide 3. The winding of the transducer of position sensor 1 is figure 1 The part of the circuit schematically indicated by refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com