Vehicle tyre

A technology for automobile tires and wheels, applied in the directions of wheels, tire measurement, tire parts, etc., can solve problems such as thermal insulation problems and increased tire wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

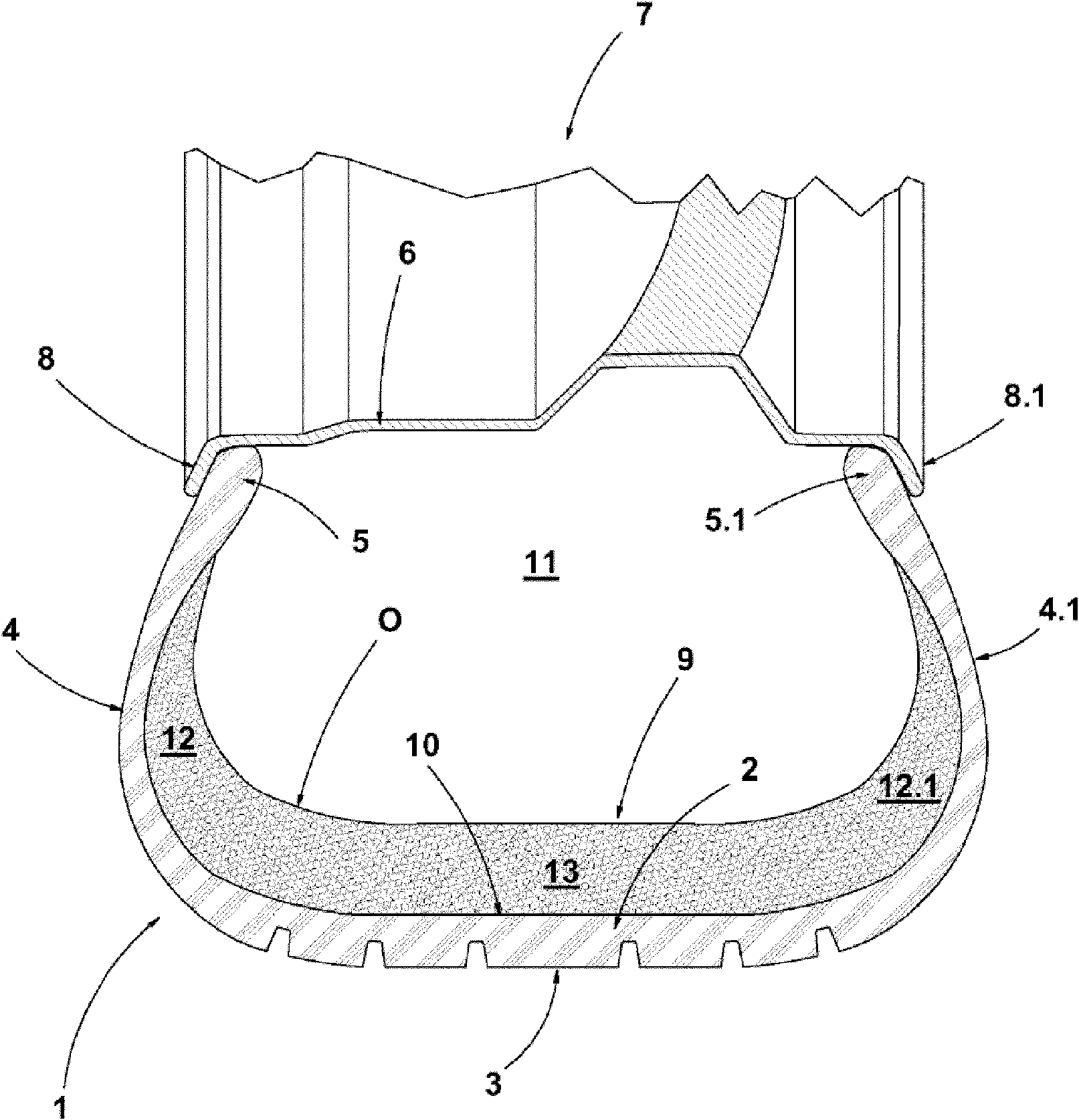

[0046] A vehicle tire 1 made of rubber or a rubber compound has a tread band 2 on the outside of which a tread 3 of the vehicle tire 1 is formed. Two sidewalls 4, 4.1 are formed on the tread band 2 and have a bead at the end of each sidewall. For simplicity, the car tire 1 is described without reinforcements or carcass. Similarly, the bead cores in the beads 5, 5.1 are also not shown. like figure 1 As shown, a car tire 1 is mounted on a rim 6 of a wheel 7 . The beads 5, 5.1 are located on the rim and are pressed against the adjoining rim flange 8, 8.1 by the inner tire pressure.

[0047] The foam insert is arranged in the vehicle tire 1 and is indicated as a whole by the reference number 9 . The foam insert 9 is attached to the inner side 10 of the tread band 2 and to the inner side of the side walls 4, 4.1. When the automobile tire 1 rotates, the foam insert 9 in contact with it also rotates with it. The foam insert 9 fills approximately 30% of the cavity 11 of the vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com