Roller driver, roller and method

A driver and rotor technology, applied in electric components, textiles and papermaking, magnetic circuit rotating parts, etc., can solve problems such as damage and mechanical damage, and achieve the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, the same reference numerals are used for the same types of components. It should be noted that the drawings are not drawn to scale as a whole and are primarily intended only to illustrate embodiments of the invention.

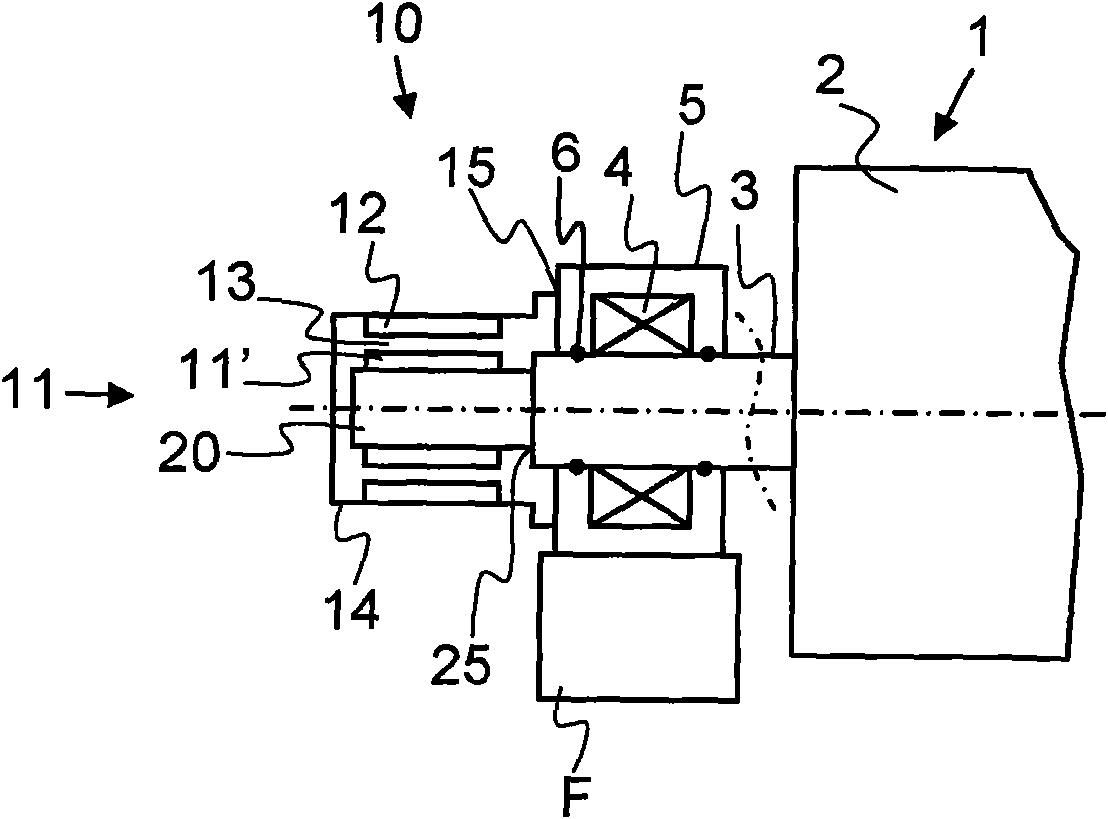

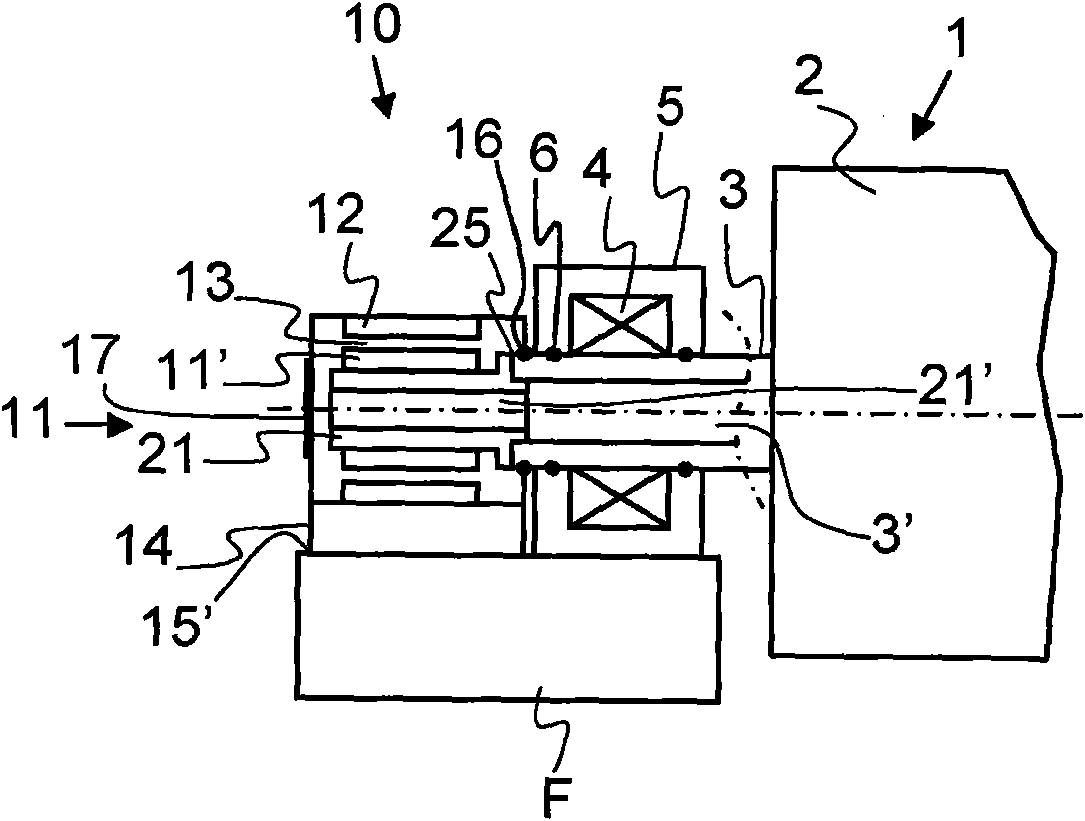

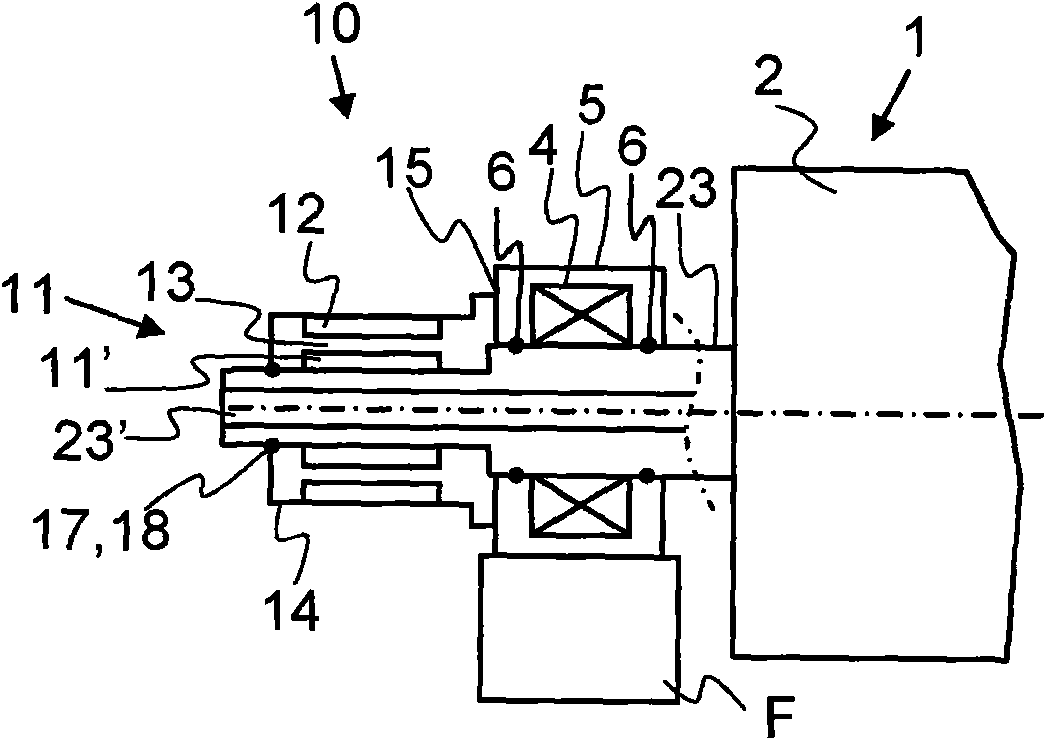

[0034] According to several preferred embodiments, Figure 1 to Figure 3A roll 1 and a roll drive 10 for the roll 1 of a fiber web machine are schematically shown. The roller 1 has a sheath part 2 and a shaft 3 fixed to the sheath part 2 by, for example, an end cap, and the shaft 3 is rotatably supported in a bearing housing 5 via a bearing 4 . The bearing housing 5 has a lubricating seal 6, and the lubricating seal 6 is arranged on both sides of the bearing 4 between the shaft 3 and the bearing housing 5 to prevent the lubricant (not shown in the figure) of the lubrication system from passing through the The insulating bushing for shaft 3 in body 5 is leaking. The bearing housing 5 is statically supported on the support F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com