Packaging device for piezoelectric component

A technology for encapsulating devices and components, applied to electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of failure, poor operation of piezoelectric sheets, damaged or broken conductive wires, etc. problem, to achieve the effect of solving vibration, preventing vibration shock and avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

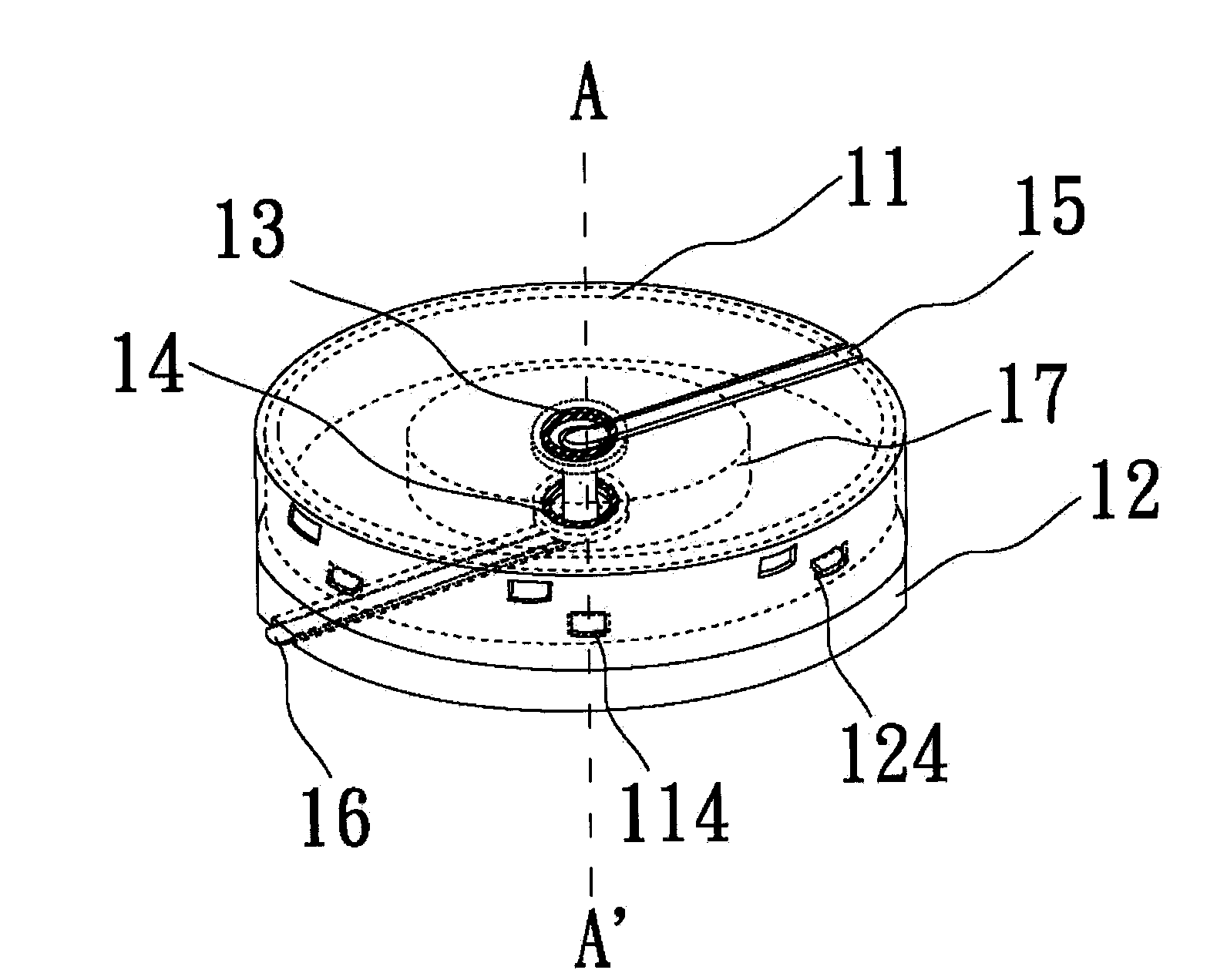

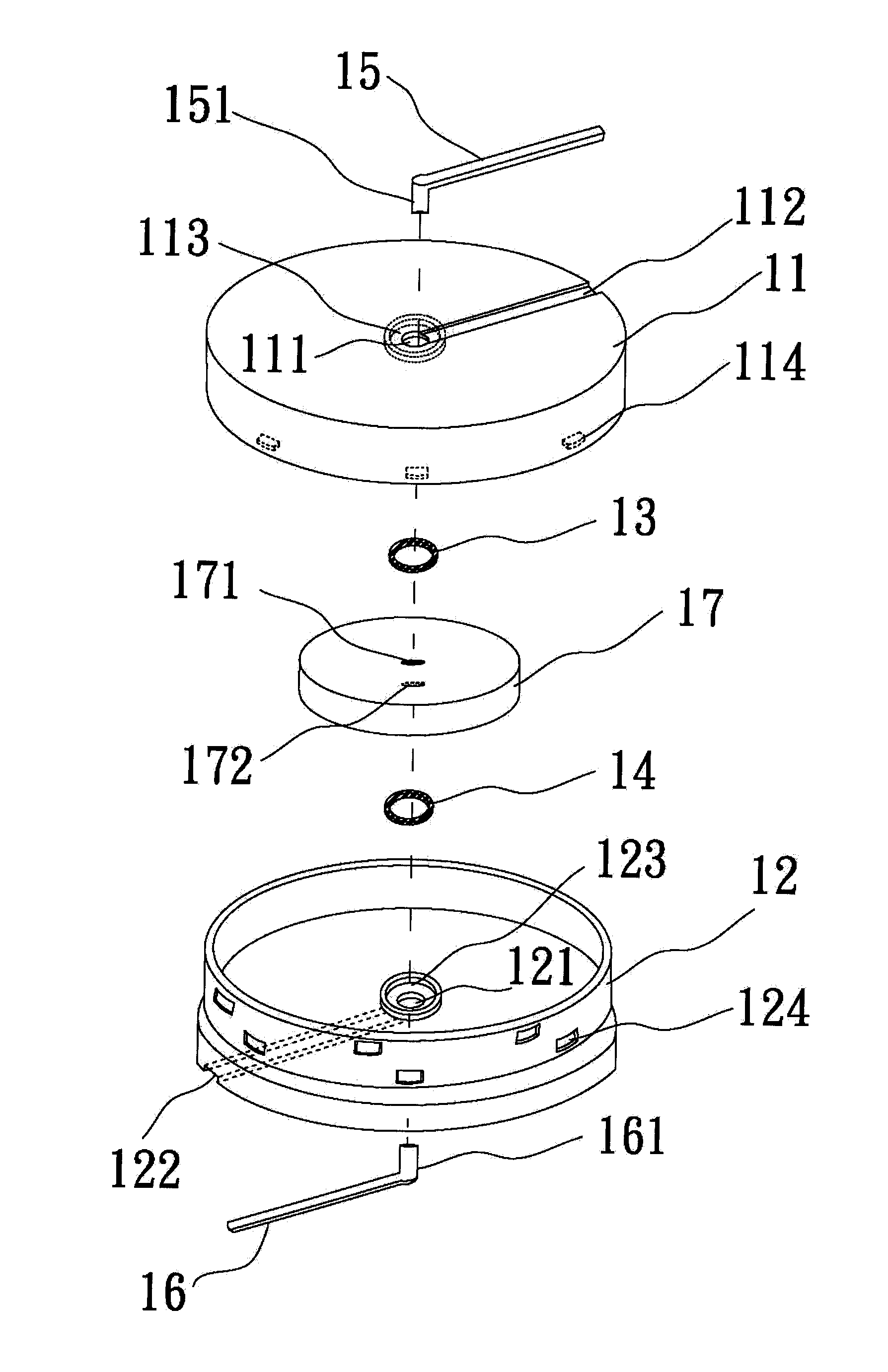

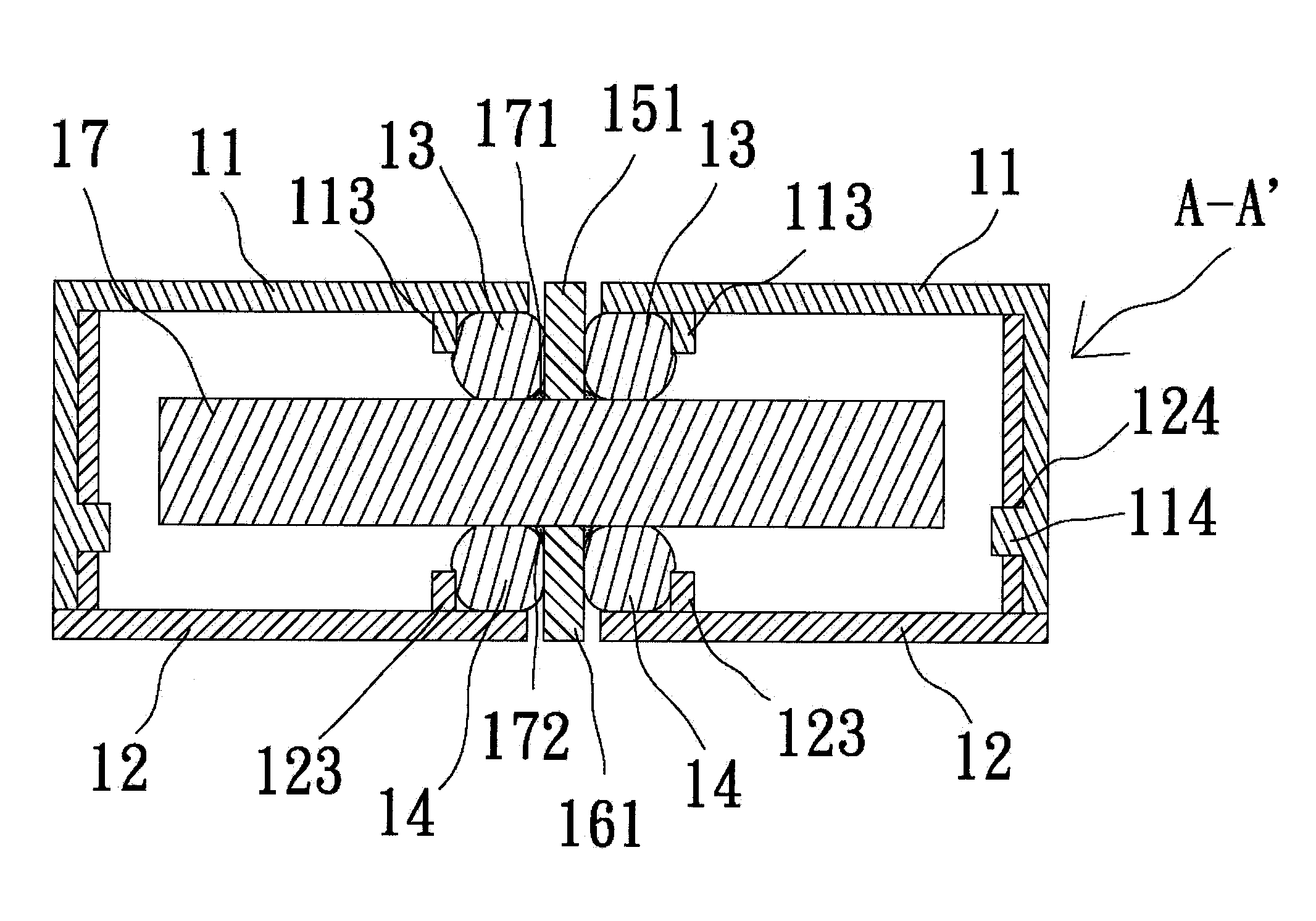

[0047] Please also refer to figure 1 and figure 2 , are respectively a perspective view and a perspective exploded view of the present invention. exist figure 2 Among them, the piezoelectric component packaging device includes an upper cover 11 and a lower cover 12, a first hole 111 and a second hole 121 are respectively provided in the middle, and a first accommodating groove 112 and a first accommodating groove 112 and a The second accommodating groove 122 is used for accommodating the first conductive sheet 15 and the second conductive sheet 16 respectively. The first conductive sheet 15 and the second conductive sheet 16 are a conductive sheet, and the bending extensions of the first conductive sheet 15 and the second conductive sheet 16 are respectively a first cylindrical conductor 151 and a second cylindrical conductive Body 161. The inner edge of the upper cover 11 and the periphery of the first hole 111 are provided with a first groove 113 for embedding a ring-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com