Balancing mass system and workbench

A technology of balancing quality and workpiece table, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems that are not conducive to simplifying the control process and cost control, many motors, and complex control algorithms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

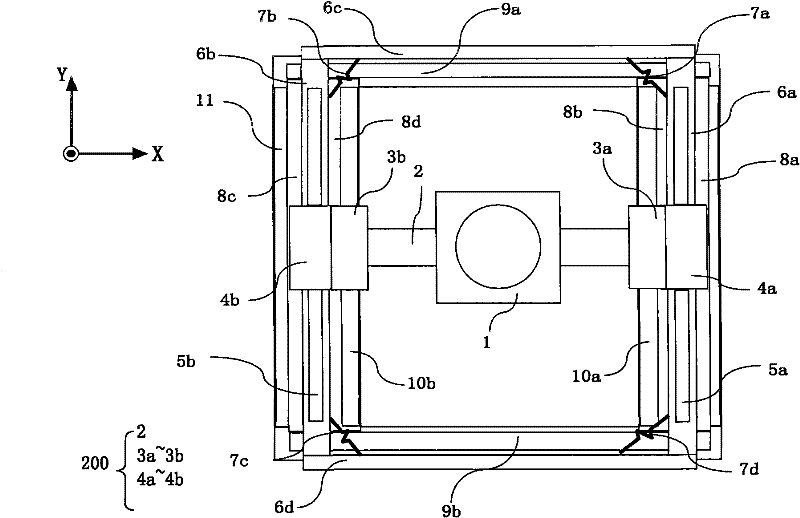

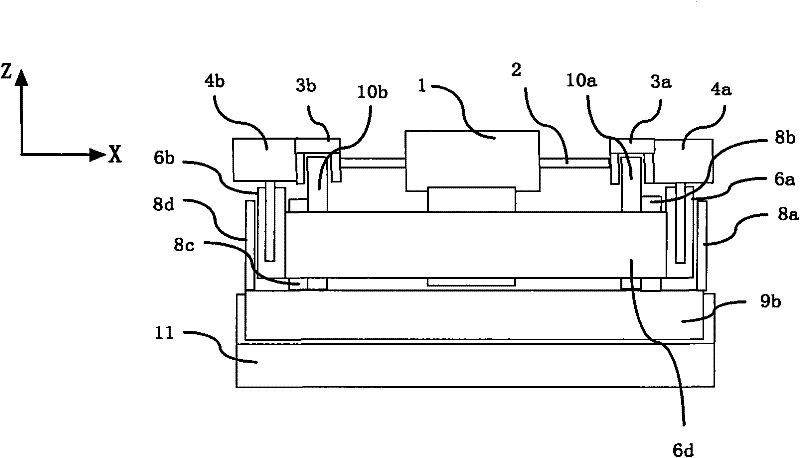

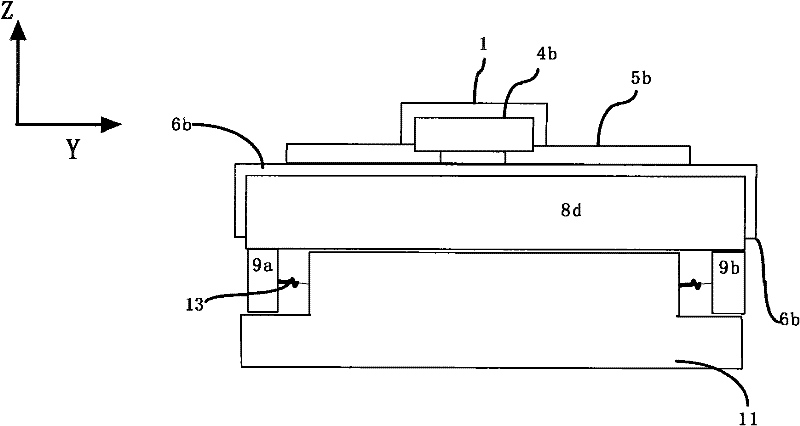

[0034] figure 1 Shown is a schematic top view of the workpiece table structure with shock absorbing device in the first embodiment of the present invention; figure 2 shown as figure 1 Schematic diagram of the front view of the middle workpiece table structure; image 3 shown as figure 1 Schematic diagram of the left view of the middle workpiece table structure. Please also refer to Figure 1 ~ Figure 3 .

[0035] According to the functional modules, the work table with shock absorbing device in this embodiment can be divided into: base 11, actuation system and balance mass system.

[0036] The base 11 is placed on a stable platform, which itself has a certain leveling ability, and is used to stably support the entire workpiece table.

[0037] The actuation system includes a fine movement ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com