Magnetic gear shifting mechanism

A speed change mechanism and magnetic gear technology, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as lack of mature technical solutions and complex mechanisms, and achieve the effect of simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

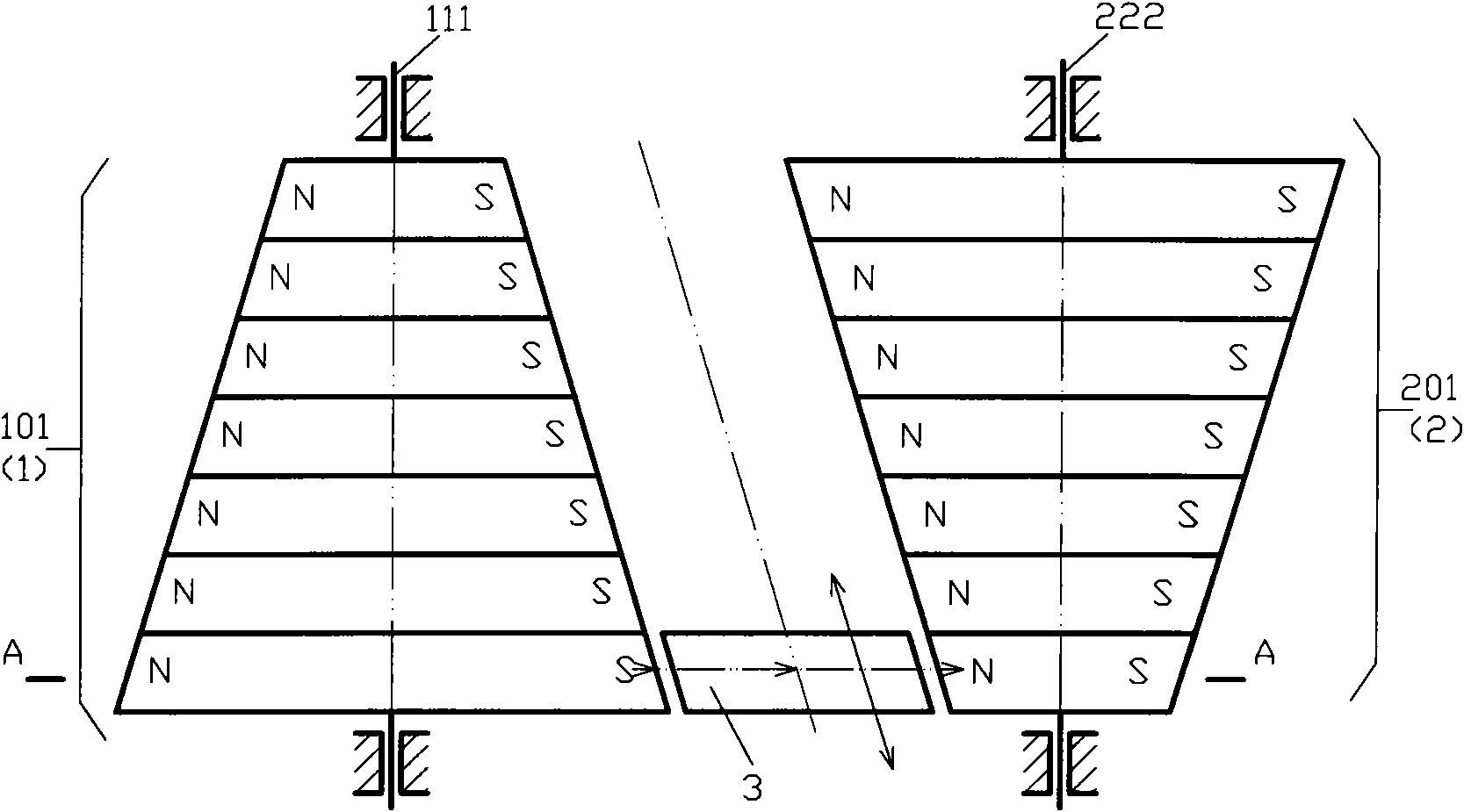

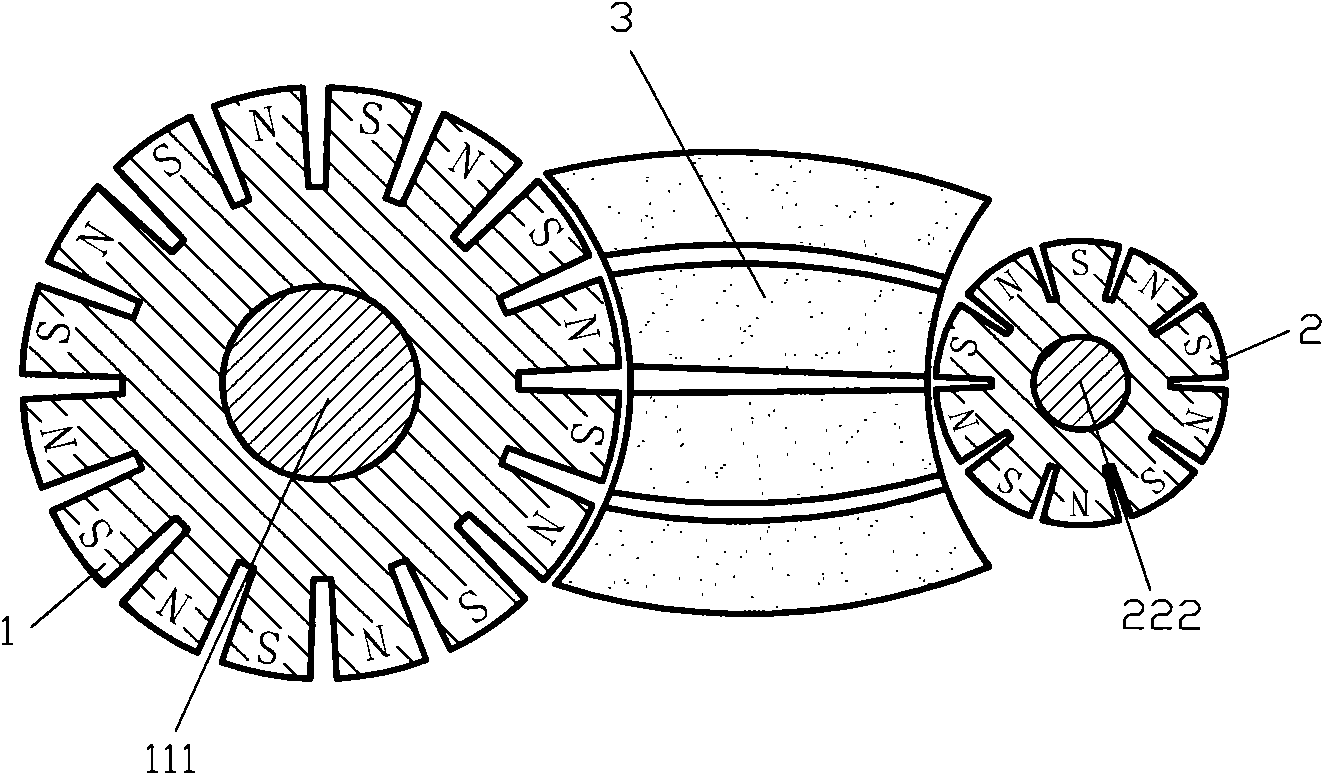

[0033] Such as figure 1 and figure 2 The shown magnetic gear speed change mechanism includes a first magnetic gear set 1 and a second magnetic gear set 2. The first magnetic gear set 1 is set to be composed of N magnetic gears coaxially arranged, and the second magnetic gear set 2 is set to consist of M magnetic gears are coaxially arranged, and the sum of M plus N is greater than or equal to 3; the diameters of the magnetic gears in the first magnetic gear set 1 are set to be the same, and the diameters of the magnetic gears in the second magnetic gear set 2 are set to be different, Or the diameters of the magnetic gears in the second magnetic gear set 2 are set to be the same, the diameters of the magnetic gears in the first magnetic gear set 1 are set to be different, or the diameters of the magnetic gears in the first magnetic gear set 1 are set to be different, The diameter of the magnetic gear in the second magnetic gear set 2 is set to be different; Between the first ...

Embodiment 2

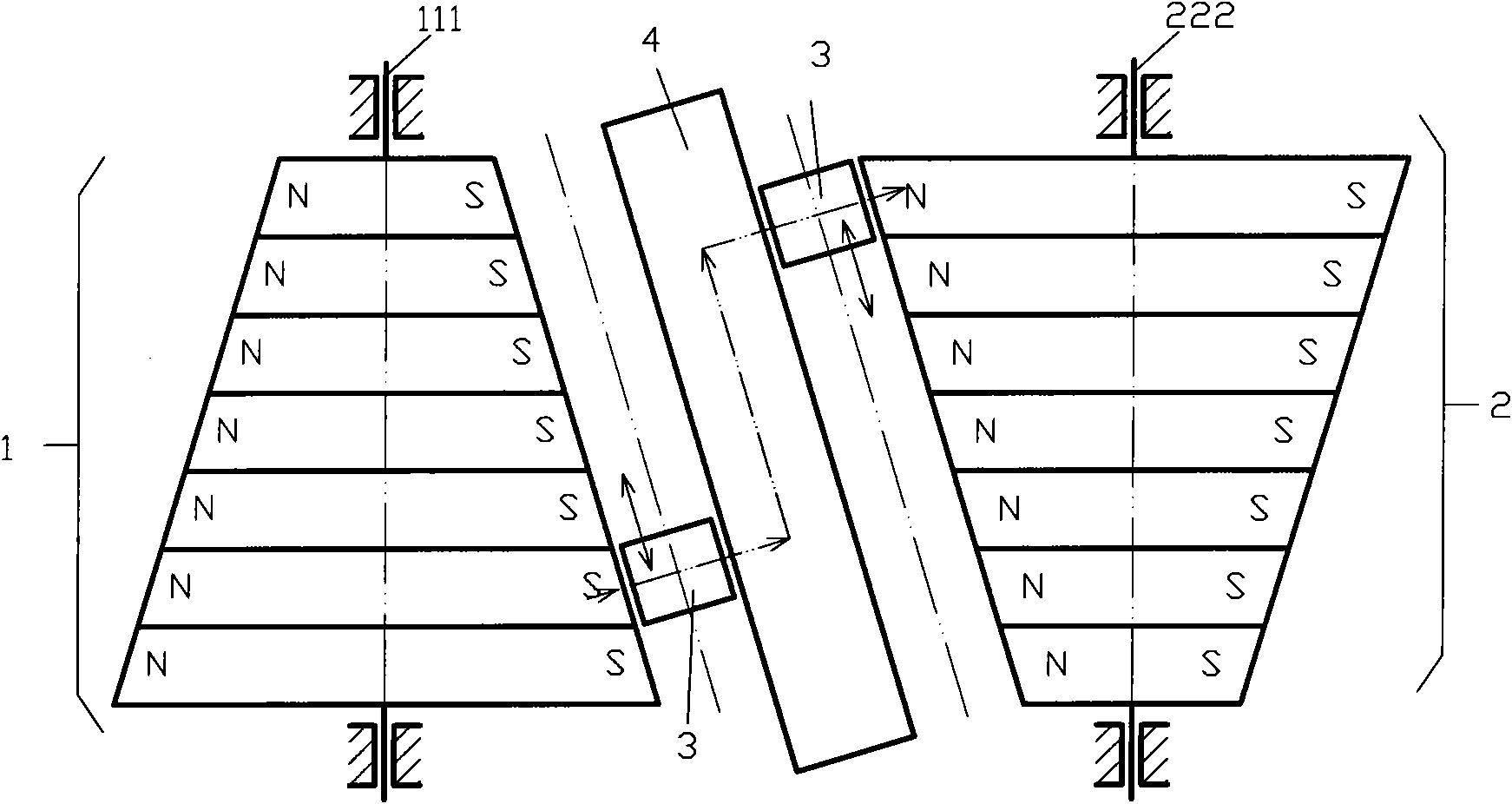

[0035] Such as image 3 The difference between the shown magnetic gear transmission mechanism and Embodiment 1 is that two moving magnetizers 3 are arranged in series between the first magnetic gear set 1 and the second magnetic gear set 2, and between the two moving magnetizers 3 There are fixed magnetizers 4 between them.

Embodiment 3

[0037] Such as Figure 4 The difference between the shown magnetic gear transmission mechanism and Embodiment 2 is that a first shape-compensating fixed magnetizer 401 is set between the first magnetic gear set 1 and the moving magnetizer 3, and a fixed magnetizer 401 is set between the moving magnetizer 3 and the second magnetizer. A second shape-compensating fixed magnetic conductor 402 is arranged between the gear sets 2 . Shape Compensation The fixed magnetic conductor has two functions: one is to compensate the shape change caused by the change of the radius of curvature of the magnetic gear, and the other is to enable the mobile magnetic conductor to maintain a relatively large and stable magnetic pole corresponding surface during the moving process to ensure sufficient torque and shape. The compensation fixed magnetizer should run through the entire length of the magnetic gear set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com