Fire-fighting centrifugal fan

A centrifugal fan and firefighting technology, which is used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of short continuous running time and poor working stability, and achieve the effect of good working stability and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

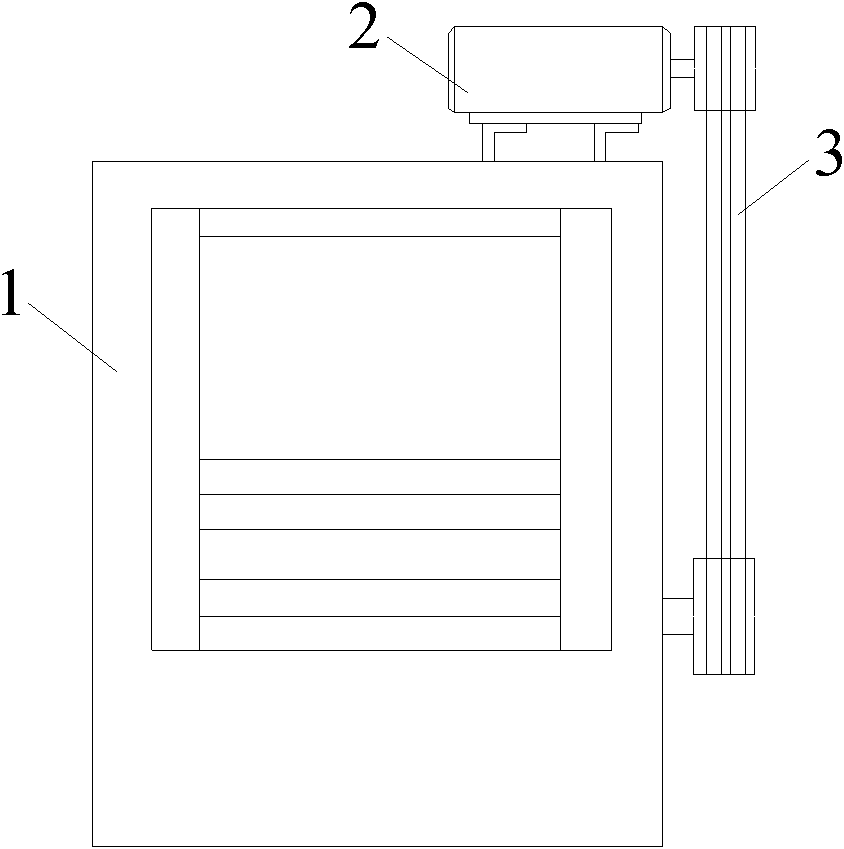

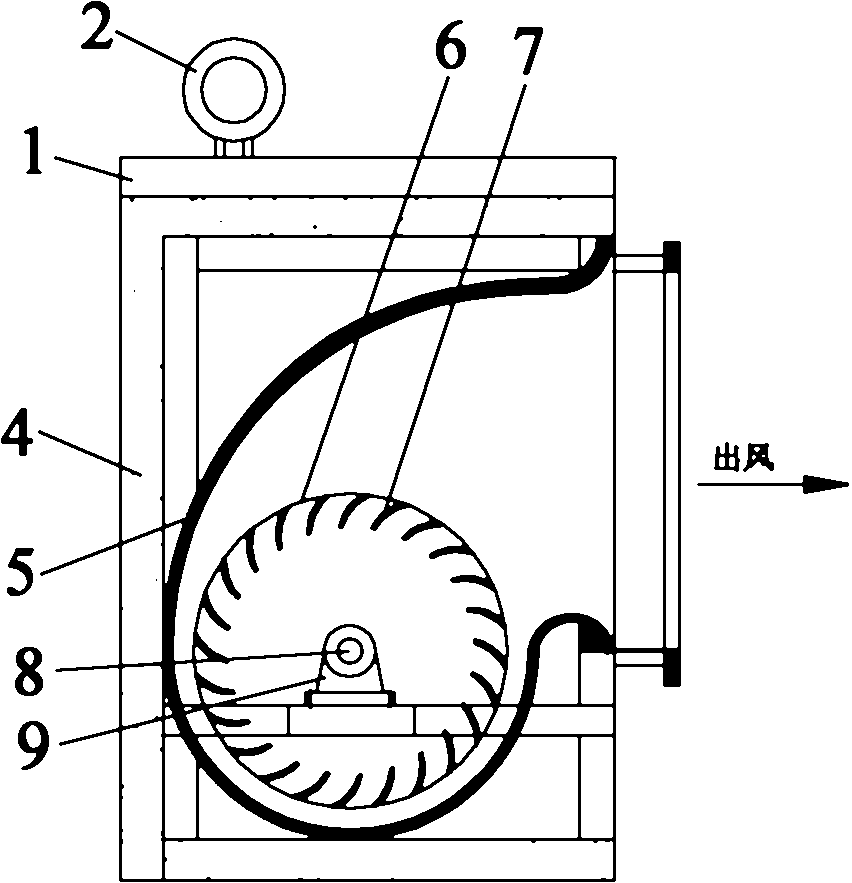

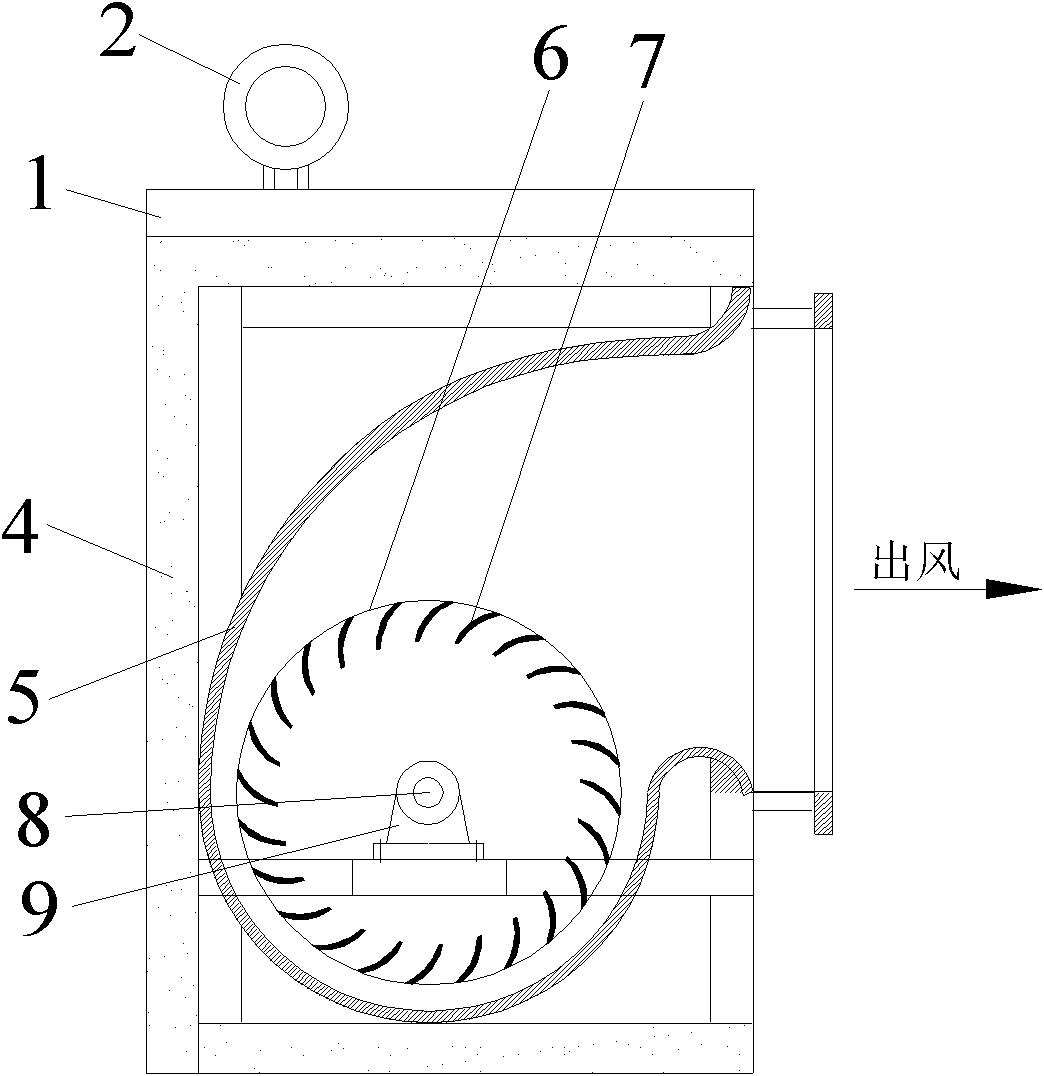

[0012] Example 1, such as figure 1 and figure 2 As shown, a centrifugal fan for fire fighting includes a box body 1 provided with an air inlet and an air outlet, the box body 1 is fixedly provided with a motor 2, and the box body 1 is provided with a volute 5. A bearing seat 9 is fixedly arranged in the volute, and the bearing seat is hinged with an impeller shaft 8 through a bearing, and the motor drives the impeller shaft 8 in the volute through a V-belt 3 to drive the impeller 6 to rotate, and the impeller 6 24 impeller blades 7 are evenly distributed on the inner circumference to form a multi-wing forward curved blade structure. In order to increase the smoke exhaust air volume, the impeller blade 7 is a forward curved blade structure. The box body 1 is a composite panel structure, and a heat insulation layer 4 is arranged in the middle of the composite panel. Further, the material of the volute is galvanized steel plate.

[0013] In the present invention, the motor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com