Double-layer volute structure of turbocharger compressor

A turbocharger and compressor technology, applied in the field of power machinery, can solve the problems of narrowing the flow rate and increasing the pressure ratio, and achieve the effects of reducing the compression loss, improving the flow capacity, and reducing the complexity of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

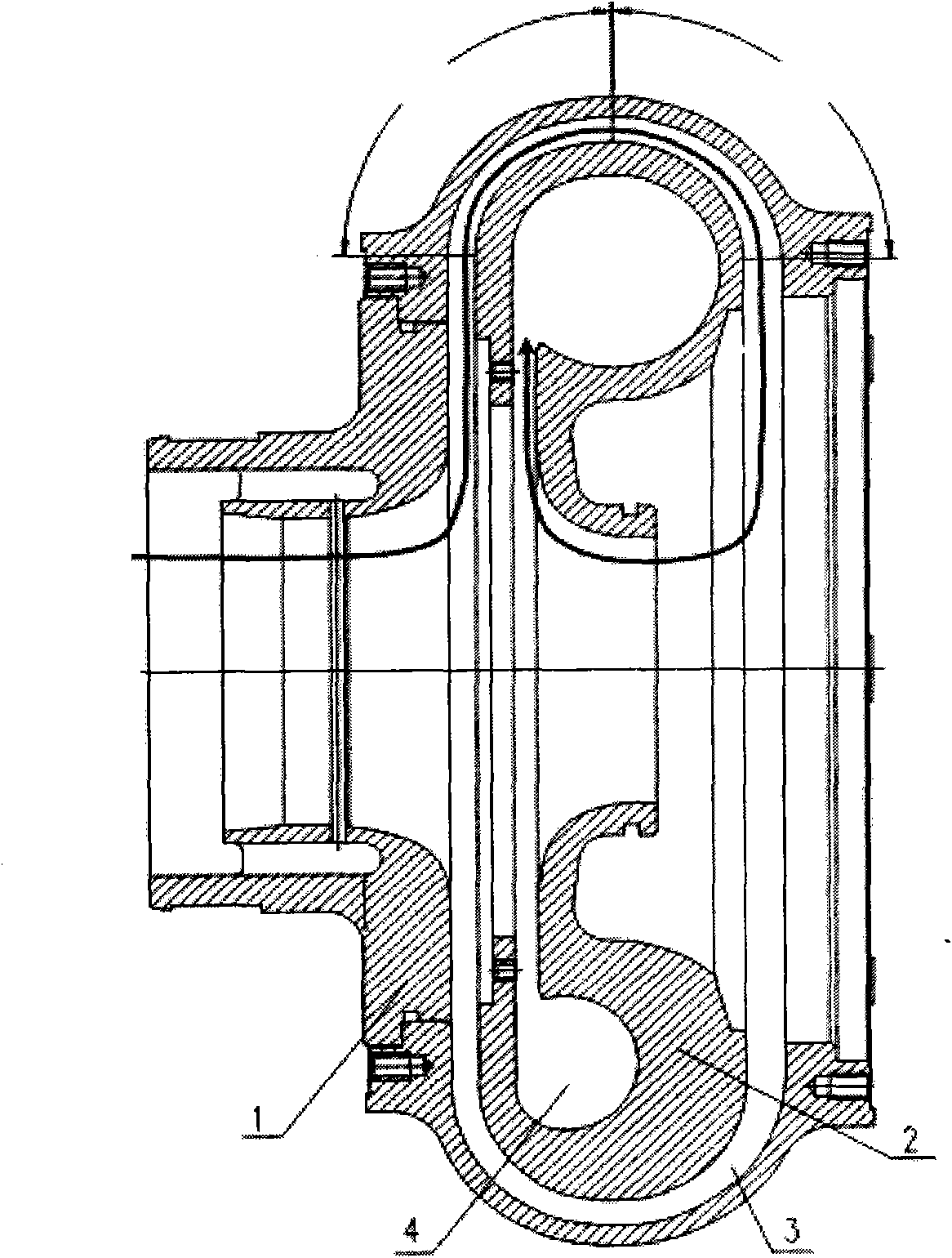

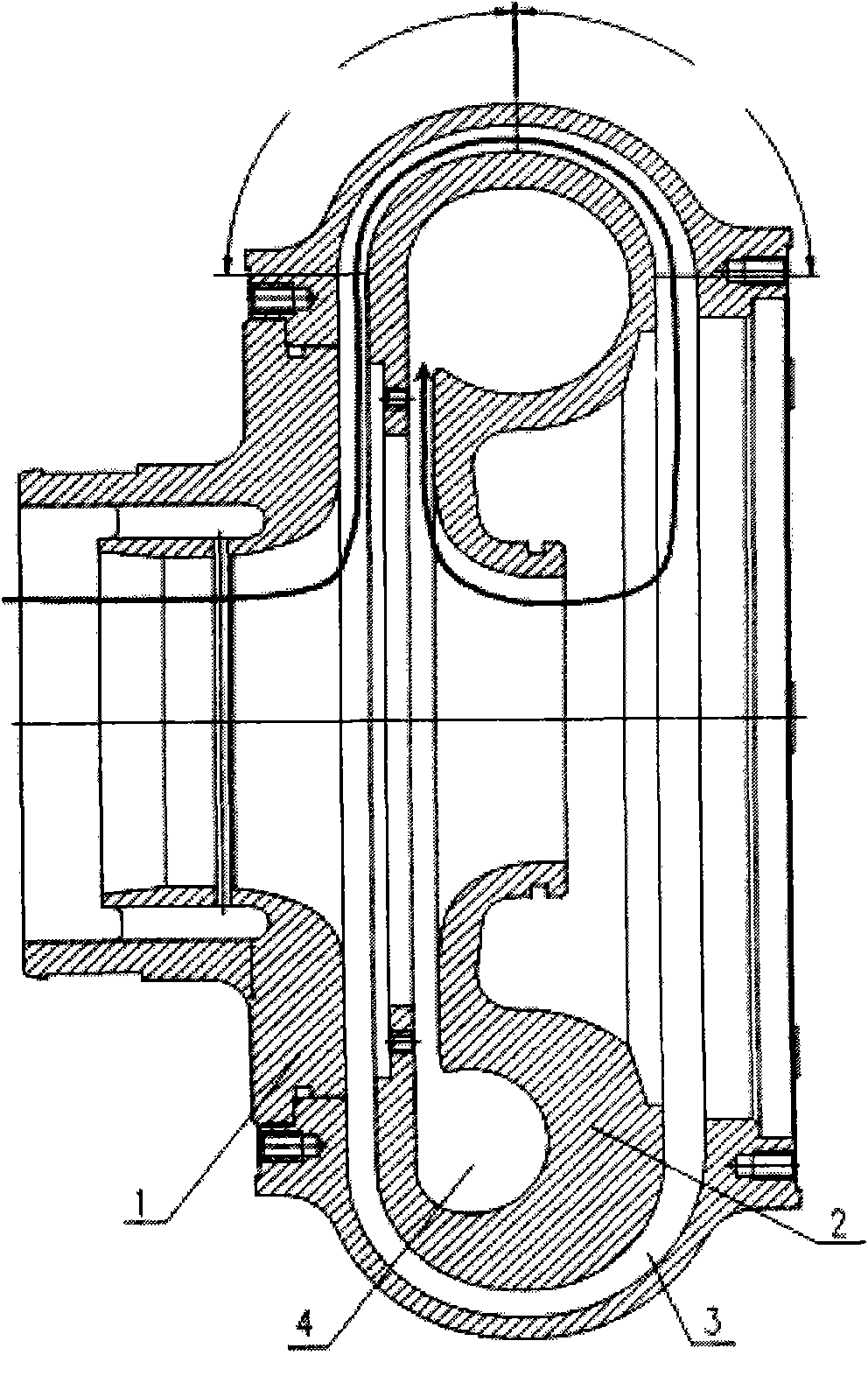

[0009] Such as figure 1 As shown, a double-layer volute of a turbocharger compressor includes an intake housing 1 and a volute 2 . The intake housing 1 is connected with the volute 2 with a pressing plate and screws. The intake shell 1 adopts an intake bypass recirculation structure, the slotting position is in the middle of the long and short blades of the first stage compressor impeller, and the slot width is 7% to 9% of the radius of the guide section of the intake shell. %. The gas flow path of the volute 2 is divided into two stages, the first stage adopts an annular flow path, and the second stage adopts a conventional snail-shaped flow path. The design features of the annular flow channel are: from the outlet of the diffuser to the largest radius of the flow channel, etc., it is designed according to the width, which belongs to the diffuser section in the annular flow channel; from the largest radius of the flow channel to the outlet of the flow channel, it is designe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com