Gas-gas combustor support device for test

A technology of a bracket device and a combustion chamber, which is applied in the directions of jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of inconvenient replacement of gas-gas injectors, heavy engine weight, and difficulty in moving heavy engines. The effect of solving the difficulty of moving, reducing interference and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

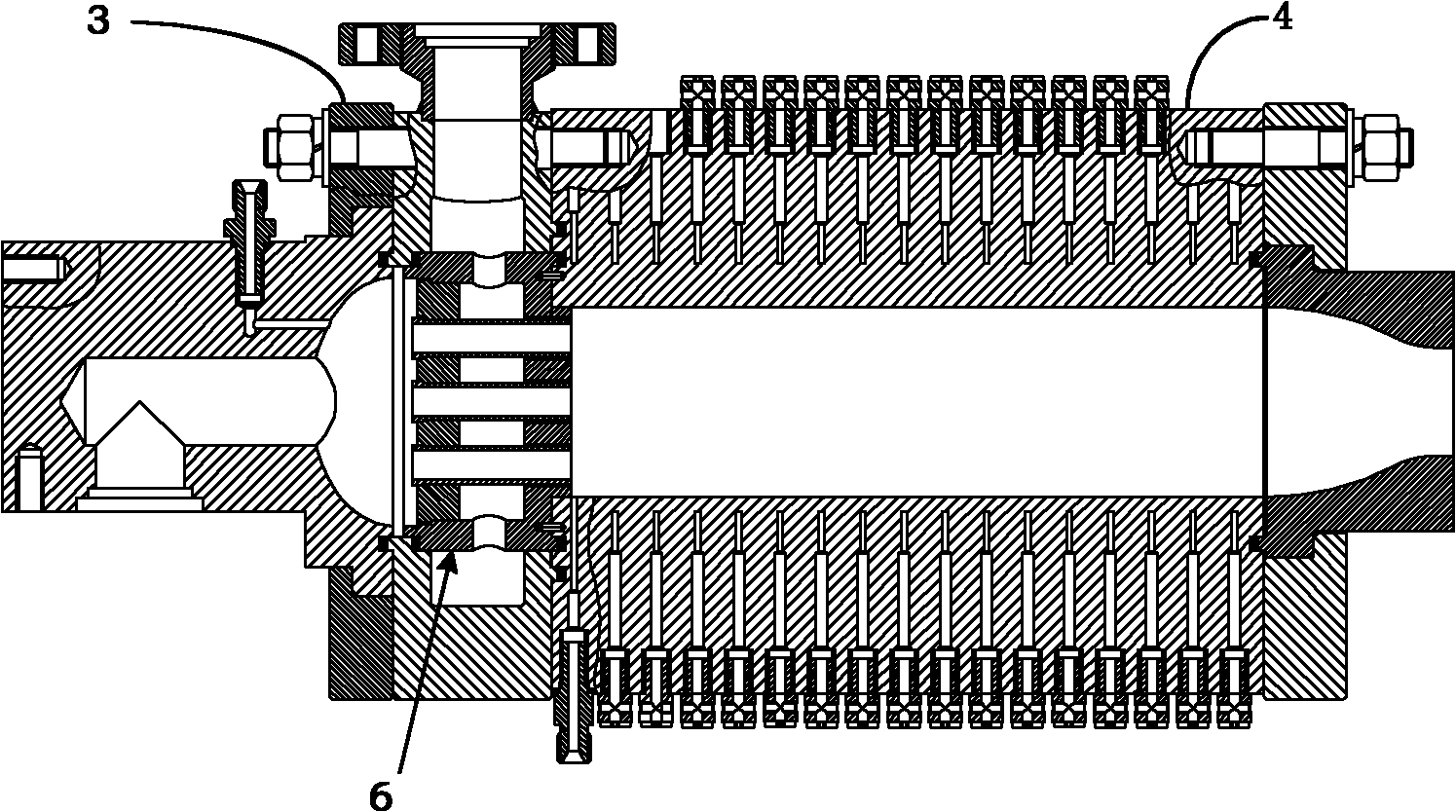

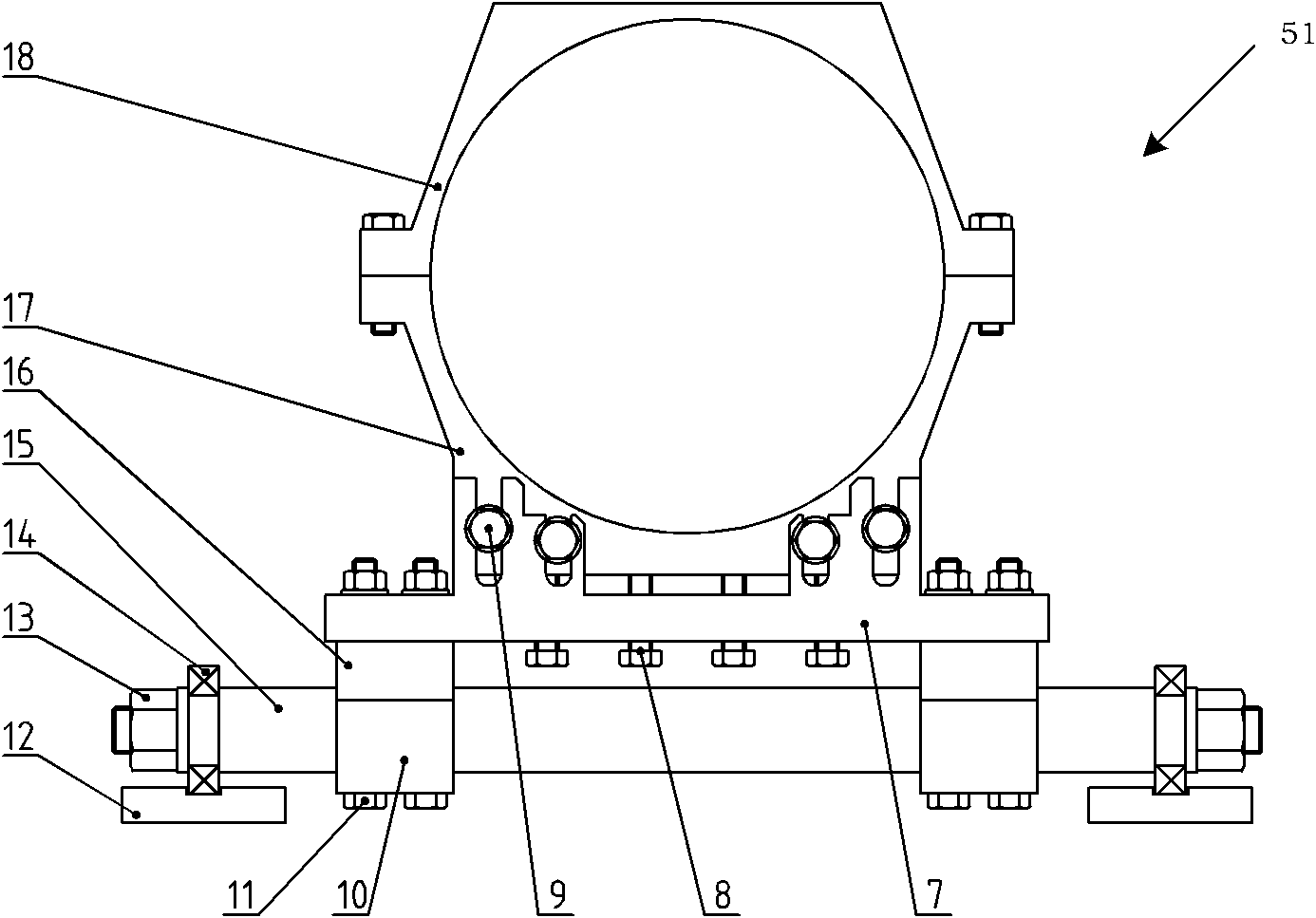

[0015] A kind of test gas combustion chamber support device of the present invention, as figure 1 As shown, it mainly includes: cement block 1, engine connecting frame 2, engine head 3, engine body 4, and engine support system 5. Described engine bracket system 5 mainly comprises rear bracket part 51 and front bracket part 52, as figure 1 As shown, the rear support part and the front support part are connected together by a load-bearing plate 16, and the rear support part and the front support part respectively have a pair of rolling bearings 14, and each pair of rolling bearings 14 is placed in the guide grooves provided at the center of two parallel guide rails 12 middle. The engine connection frame 2 is fixed on the cement block 1; the engine head 3 is installed on the connection frame 2; the engine body 4 is placed on the engine support system 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com