Organic biogas slurry nutrient solution with stable property and production method thereof

A technology for stabilizing performance and nutrient solution, which is applied in the fields of organic fertilizer, organic fertilizer preparation, biological organic part treatment, etc. It can solve problems such as the influence of biogas slurry stability, and achieve the effect of promoting photosynthesis, promoting development and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

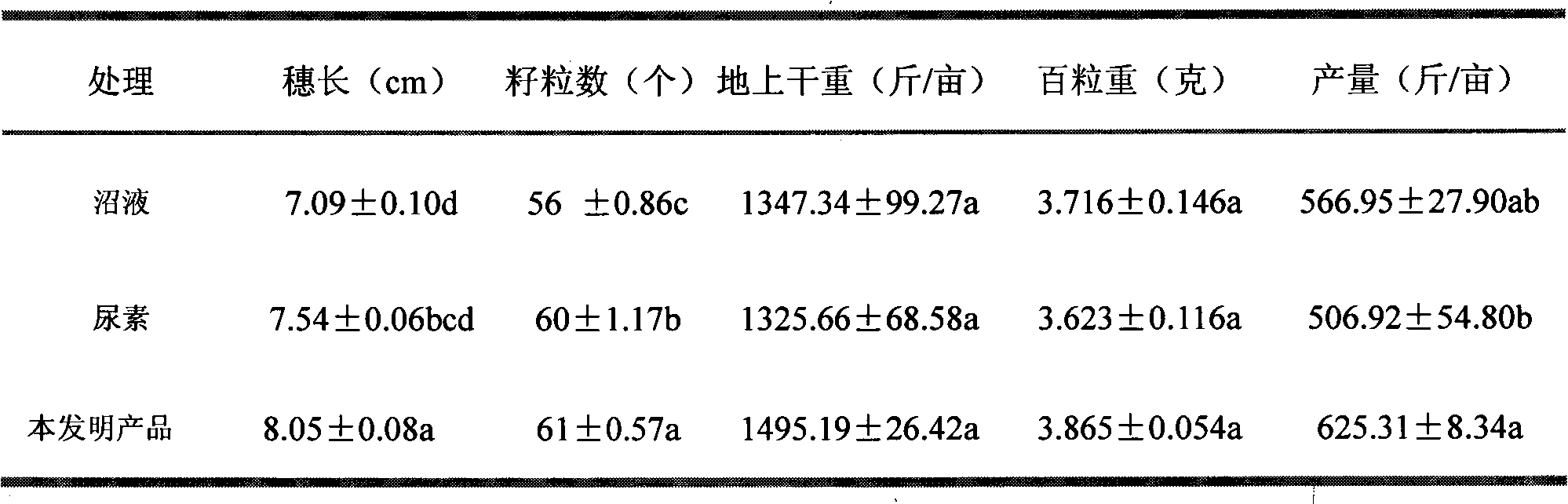

Examples

Embodiment 1

[0025] A liquid with a solid content of less than 1% is obtained by anaerobic fermentation of cow dung as raw material to produce biogas, and is used for standby; low-rank coal is selected from Inner Mongolia lignite,

[0026] Bacillus strains were inoculated into the seed tank Fu for 12 hours according to the conventional method, and then inoculated into the fermentation tank for 24 hours to obtain the bacterial liquid obtained after fermentation, and the bacterial concentration was 1×10 8 cfu / mL, spare,

[0027] Mix 85kg of the above-prepared biogas slurry and 10kg of -60mesh Inner Mongolia lignite into the fermentation tank, and at the same time add 7kg of the above-prepared Bacillus culture solution and mix them for 20 days at a temperature of 25-28°C to obtain The biogas slurry organic nutrient solution, the pH of the product is stable at 7.5-7.8 for more than 2 months, the total N reaches 2800mg / kg, and the soluble P reaches 138.6mg / kg.

Embodiment 2

[0029] A liquid with a solid content of less than 1% is obtained by anaerobic fermentation of pig manure to produce biogas, and is used for standby; the low-rank coal is selected from Xinjiang weathered coal,

[0030] Bacillus strains were inoculated into seed tanks and cultivated for 18 hours according to conventional methods, and then inoculated into fermentors to ferment for 18 hours. 8 The bacillus culture solution of cfu / mL, standby,

[0031] Mix 80kg of the above-prepared biogas slurry and 18kg of -80 mesh Xinjiang weathered coal into the fermentation tank, and at the same time add 8kg of the above-prepared Bacillus culture solution and mix them to ferment for 20 days at a temperature of 25-28°C to obtain a stable Biogas slurry organic nutrient solution with high performance, the product pH is 8.7-8.9, the total N reaches 3100mg / kg, and the soluble P reaches 154mg / kg.

Embodiment 3

[0033] A liquid with a solid content of less than 1% is obtained by anaerobic fermentation of mixed manure from cow dung and pig manure to produce biogas, and it is used for standby; coal gangue is used for low-rank coal.

[0034] Bacillus strains were inoculated into seed tanks and cultivated for 24 hours according to conventional methods, and then inoculated into fermentors to ferment for 12 hours to obtain the bacterial liquid with a concentration of 1.2×10 8 The bacillus culture solution of cfu / mL, standby,

[0035] Mix 75kg of the above-mentioned biogas slurry, 20kg of -80 mesh coal gangue, and 5kg of -2mm straw into the fermentation tank, and at the same time, insert 10kg of the bacillus liquid prepared above and mix well, and ferment for 20 days at a temperature of 25-28°C to obtain Biogas slurry organic nutrient solution with stable performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com