Automatic loading and unloading truck for refrigerators

An automatic technology for loading and unloading vehicles, applied in the direction of lifting devices, etc., can solve problems such as potential safety hazards, and achieve the effects of improving work efficiency, realizing mechanical automation, and reducing labor in refrigerator loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

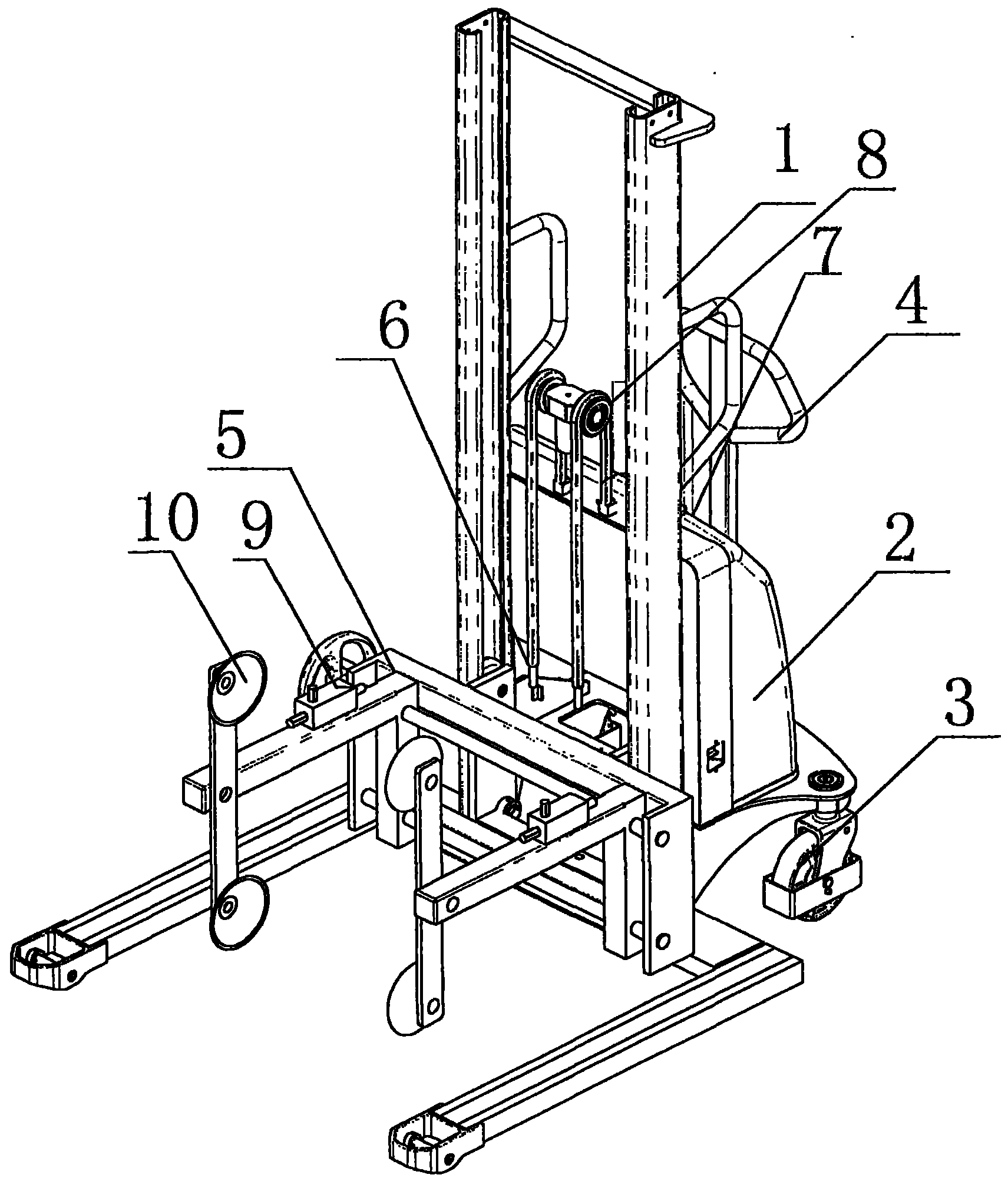

[0008] exist figure 1 Among them, the present invention provides an automatic loading and unloading vehicle for refrigerators, which includes a vehicle frame 1, a push-pull device is provided on one side of the vehicle frame 1, a clamping device is provided on the other side, and a box body 2 is provided on the push-pull device. The bottom of the box body 2 is a roller 3, and a push rod 4 is arranged on the roller 3, and a hydraulic drive device is provided in the box body 2, and the drive device is set as a hydraulic drive device. The clamping device includes a lifting clamp 5, and the drive device passes through a transmission belt. 6 and the lifting clamp 5 are transmission connections, and the driving device drives the lifting clamp 5 to rise or fall through the transmission belt 6, and an adsorption device is arranged on the inner surface of the two clamp arms of the lifting clamp 5, and the adsorption device is set as a vacuum skin suction 10. The adsorption control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com