Load power takeoff (PTO) device for high-lift portal crane

A technology of cranes and gate seats, which is applied in the field of hoisting machinery, can solve problems such as wire rope damage, increased wire rope wear, and tension sensor overload, so as to avoid frequent work, improve work efficiency, and increase accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

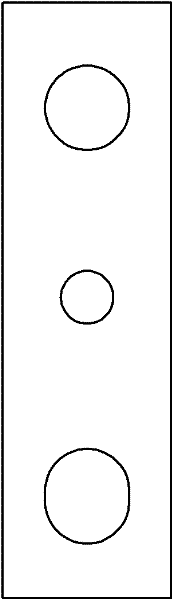

Image

Examples

Embodiment 1

[0019] The load force take-off device of a high-lift gantry crane includes a tension sensor 4 and a stress release device for fixing the hoisting wire rope. The stress release device includes a beam 16, a thrust ball bearing 15, a rotary joint 18, a standard wire rope sheath 19, and a standard wire rope The sleeve 19 is fixedly connected under the swivel joint 18, and a thrust ball bearing 15 is arranged between the swivel joint 18 and the crossbeam 16. The swivel joint 18 is fixedly connected to the crossbeam 16 in a freely rotatable manner, and the two ends of the crossbeam 16 are connected to tension sensors through the pull plate 8. 4. The output of the tension sensor is connected to the main engine of the moment limiter in the crane cab.

[0020] The data signal of the heavy load is obtained through the pull sensor, and the signal is transmitted back to the moment limiter host in the cab. The stress release device is used to securely fix the wire rope and release the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com