Small tractor plough

A technology for small machines and ploughs, which is applied to ploughs, agricultural machinery and implements, applications, etc., can solve the problems of increased maintenance costs, short handrail design, and laborious manipulation, and achieves reduced maintenance costs, longer handrail design, and convenient lifting and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

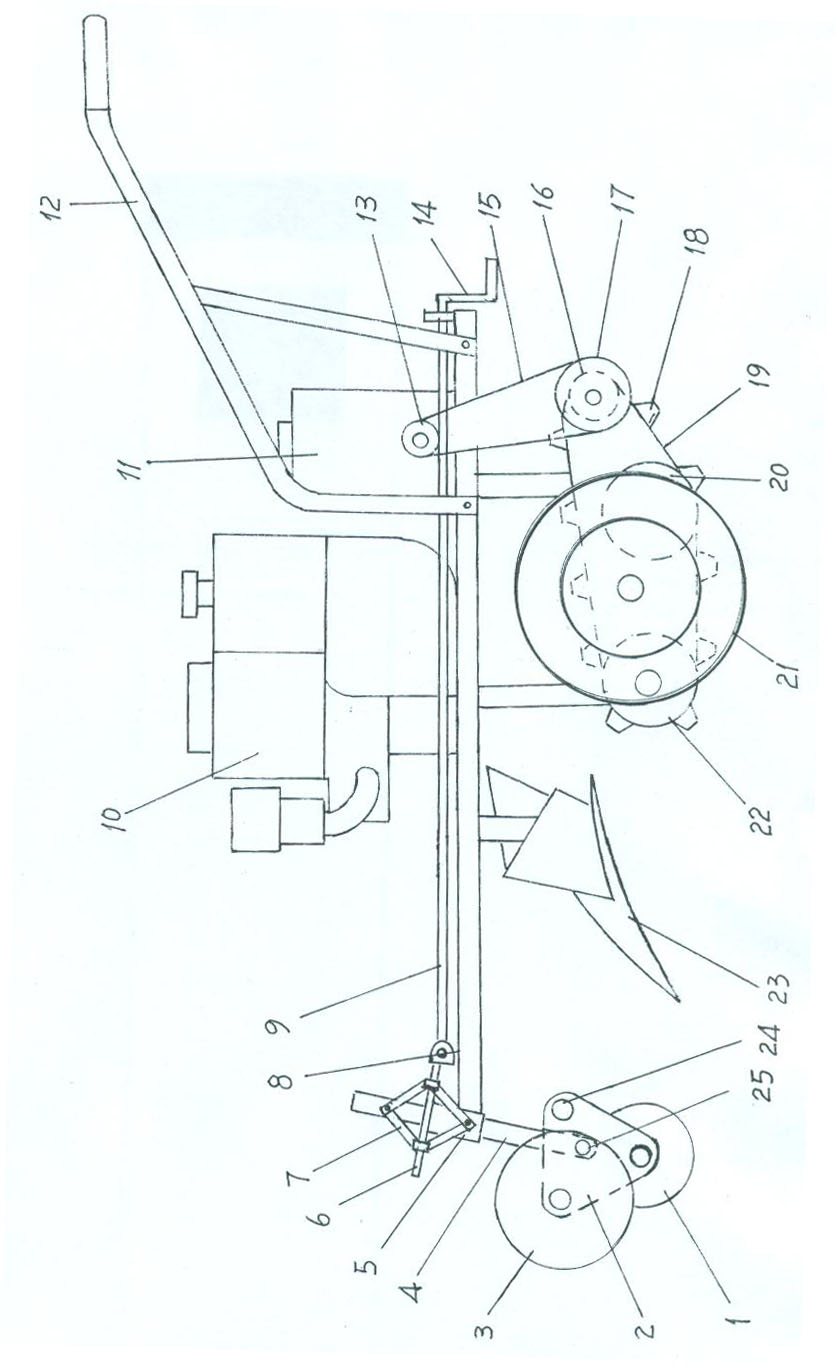

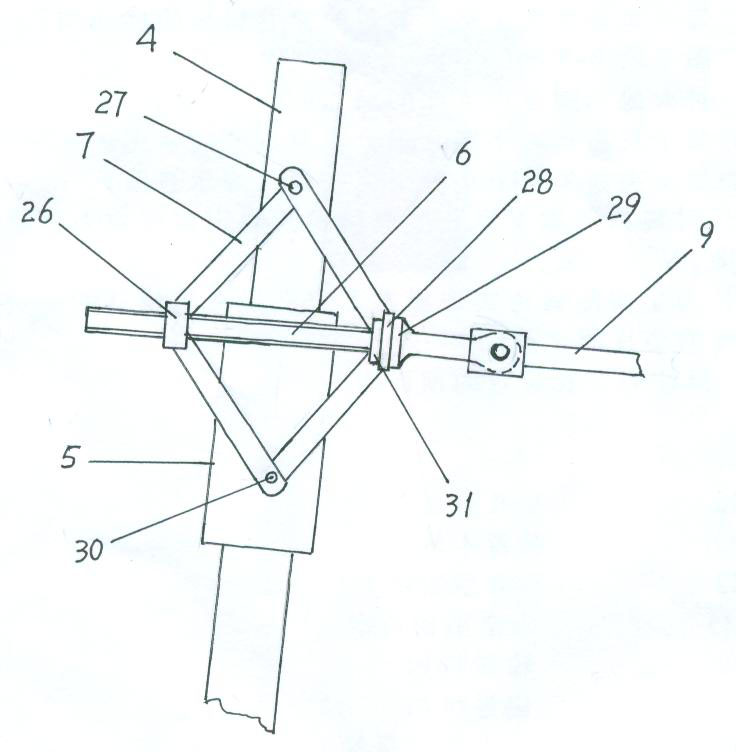

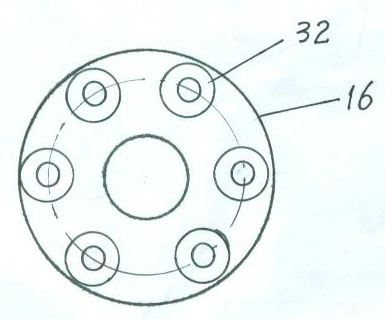

[0018] See figure 1 -8, the concrete structure is as follows: the rear traveling wheel 21 that can be folded is assembled in the middle rear part of frame 8 by prior art structure. Assemble up and down adjustable guide rod 4 in the conduit 5 of frame 8 front ends, guide rod 4 lower ends assemble front guide wheel group by prior art, promptly assemble the triangular wheel plate 2 that can rotate by rotating shaft 25, two of wheel plate 2 Rotate and assemble single wheel 1 and the double butterfly wheel 3 that can walk on the ridge respectively on the corner, and assemble limit latch 24 on the other corner. Guide rod 4 can select two kinds of adjustable structures up and down: a kind of as figure 1 , 2 As shown, a set of four-bar linkage mechanism is set, and the upper and lower hinge shafts 27, 30 of the four-bar linkage 7 are respectively connected to the guide rod 4 and the conduit 5, a screw sleeve 26 is connected to the front hinge shaft, and a rear hinge shaft Connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com