Waveguide flat array antenna

An array antenna and waveguide technology, applied in antennas, antenna coupling, antenna arrays, etc., can solve the problems that flat-panel antennas cannot meet the system requirements at the same time, cannot meet the system use requirements, and are not easy to mass-produce, so as to reduce the feeding network layer Number, efficiency improvement, avoiding the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

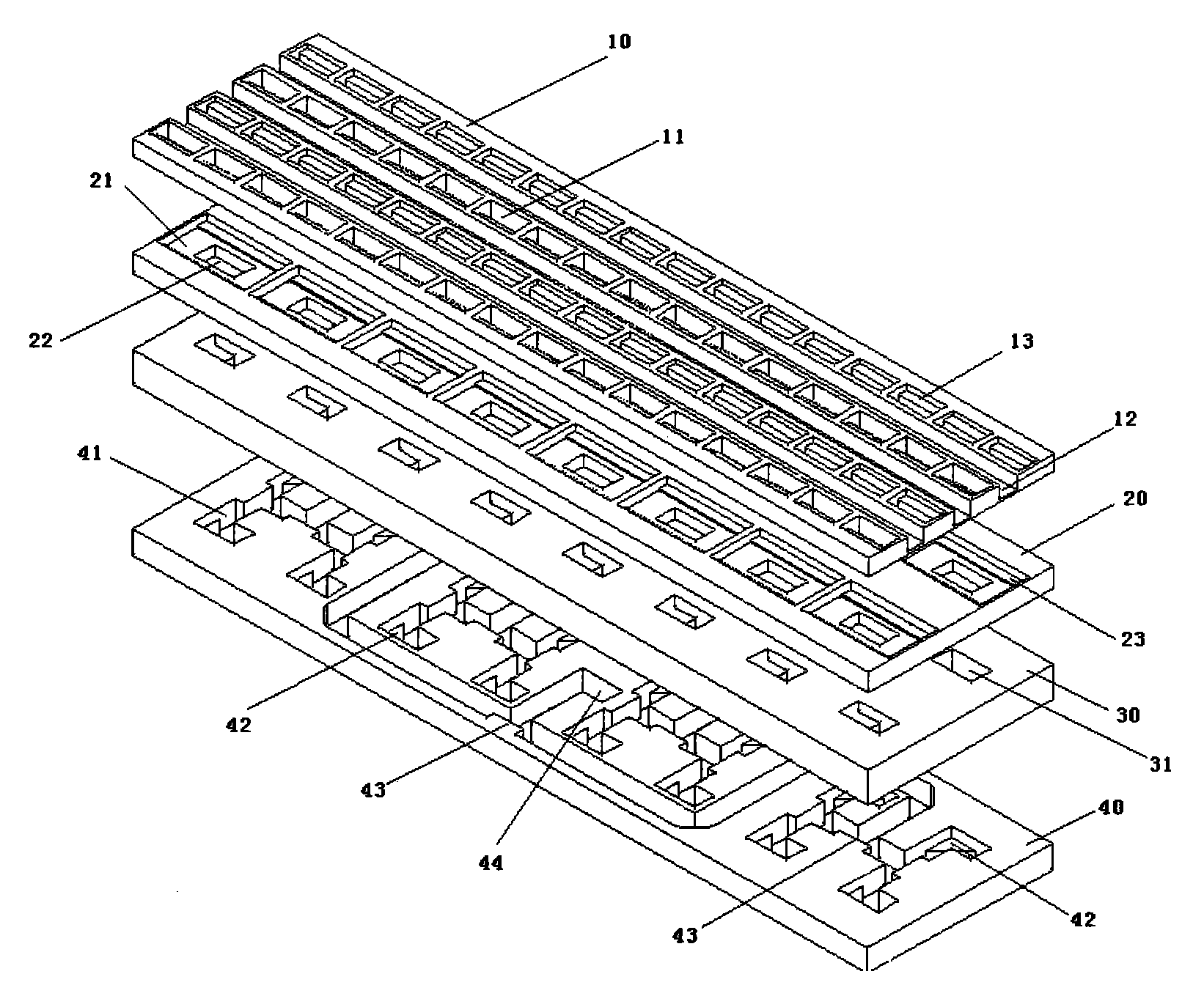

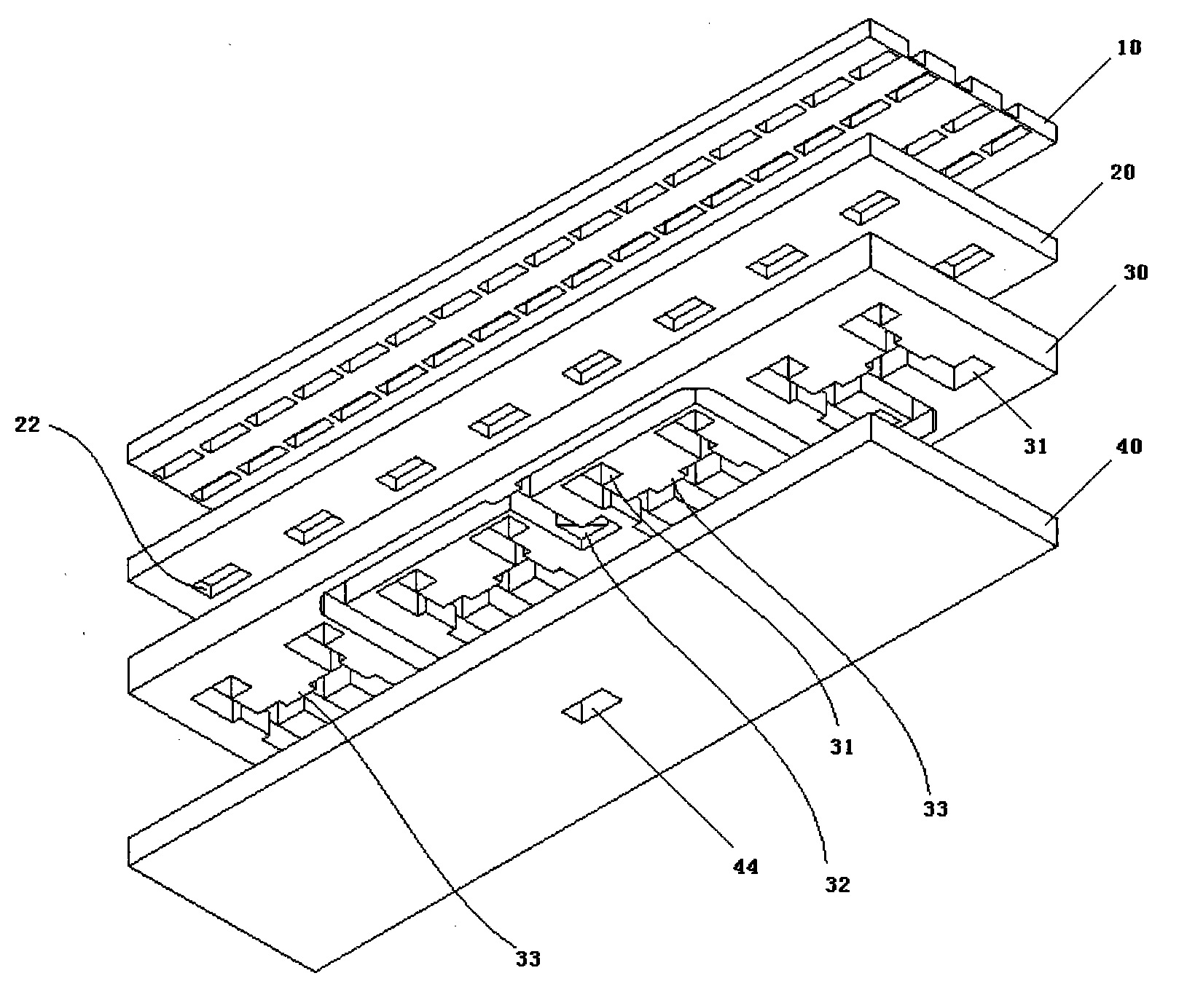

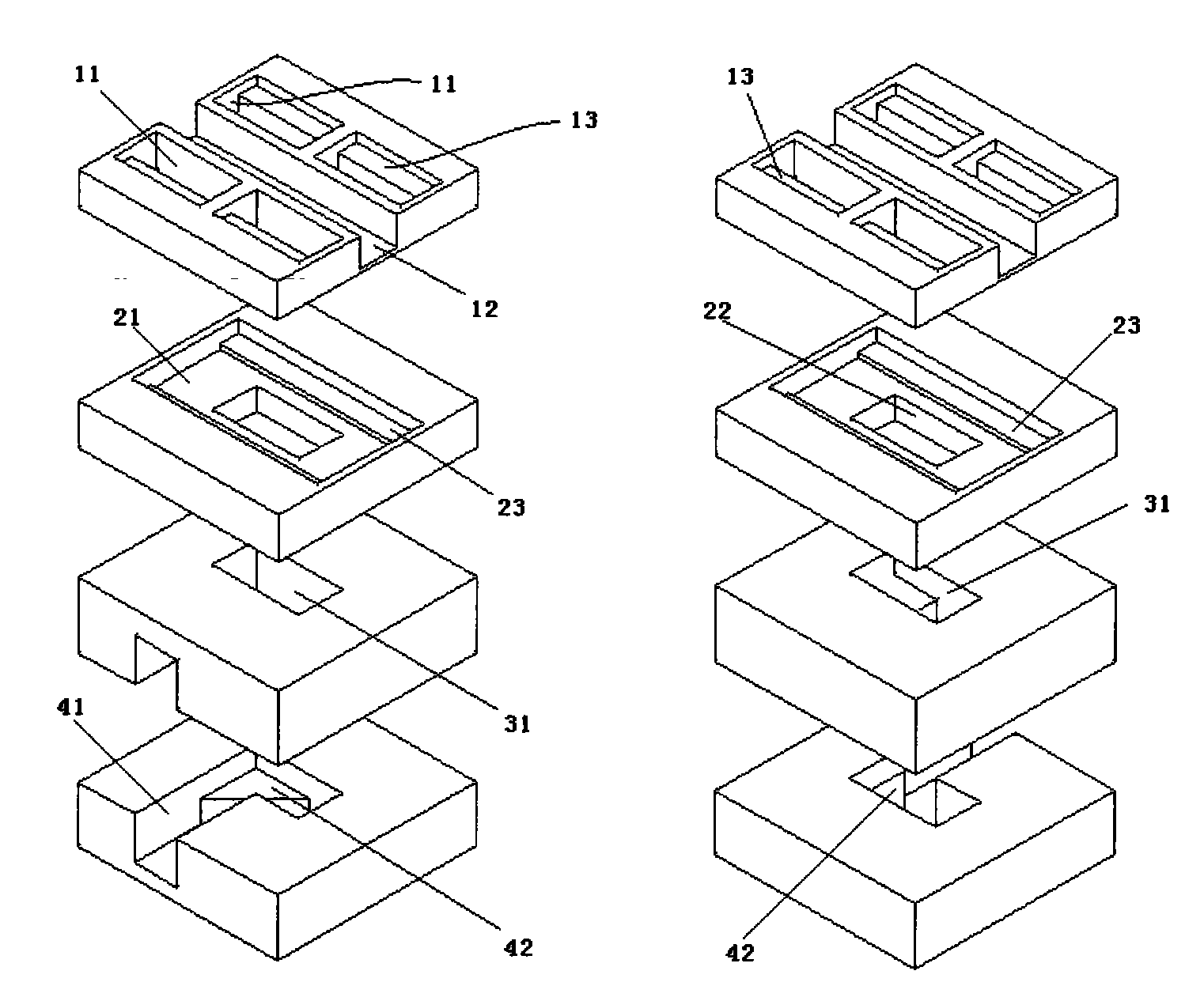

[0026] Such as figure 1 , 2 The shown antenna is composed of four layers, which are the radiation layer 10, the rectangular exciting cavity layer 20, the upper layer 30 of the waveguide E-T feeding network, and the lower layer 40 of the waveguide E-T feeding network. The four-layer structure is stacked together in order to form a flat panel antenna. The input and output waveguide port 44 located in the middle of the lower layer 40 of the waveguide E-T feeding network is the final input and output port of the signal.

[0027] Several rectangular opening waveguides 11 on the radiation layer 10 complete the conversion of the radio frequency signal from the circuit to the free space. Compared with various shapes of microstrip patches (rectangular, circular, elliptical, etc.), oscillators, slots, etc., which work on resonance characteristics, the rectangular opening waveguide 11 has high-pass characteristics, so the operating bandwidth is large. Rectangular opening waveguides 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com