Structure for dropping steel balls

A technology of lowering balls and steel balls, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., and can solve the problems of bearing scrapping, low efficiency, large or small number of steel balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

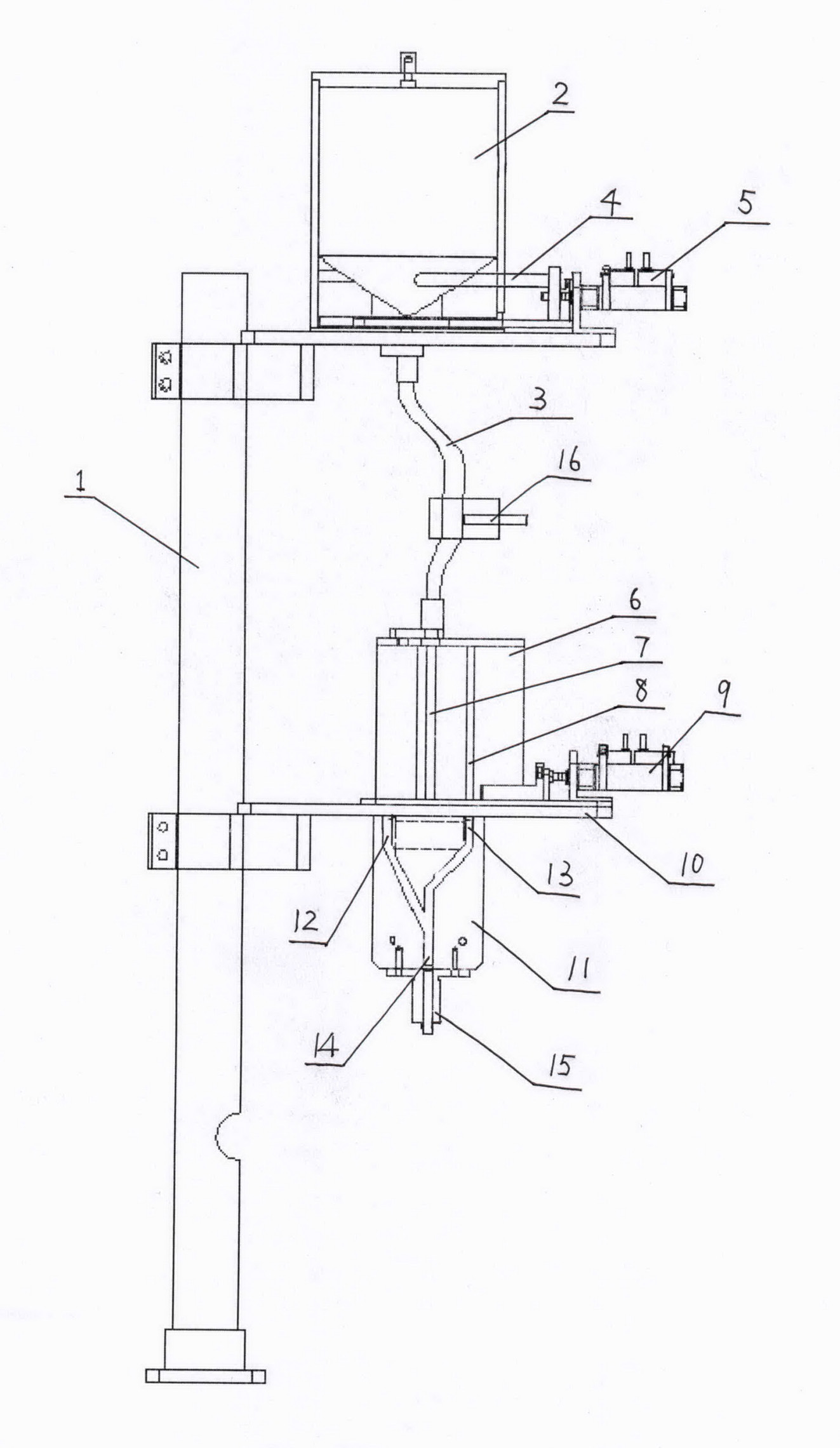

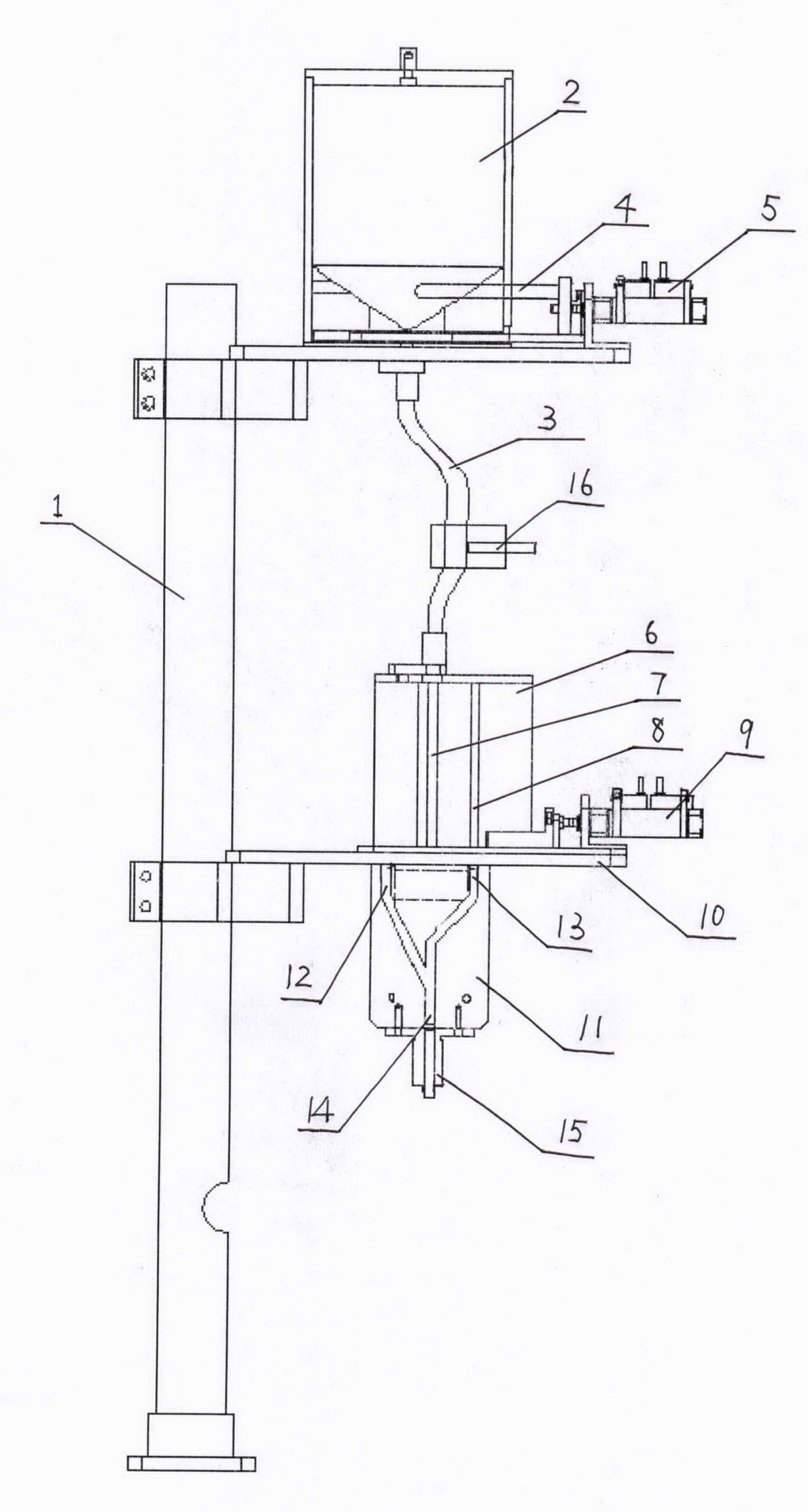

[0008] See figure 1 , which includes a column 1, the top of the column 1 is connected with a ball pin 2, the outlet of the ball pin 2 is connected with the inlet of the inverted ball tube 3, a stop plate 4 is installed above the exit of the ball pin 2, and one end of the stop plate 4 A cylinder 5 is connected. The lower part of the inverted ball tube 3 is the slider 6, and the outlet of the inverted ball tube 3 corresponds to the lower ball through holes 7, 8 inside the slider 6, and there are two vertical lower ball through holes 7, 8 inside the slider 6 , the lower ball through holes 7 and 8 have the same aperture, one side of the slider 6 is connected with a linear cylinder 9, the horizontal line connecting the lower ball through holes 7 and 8 is parallel to the straight line of travel of the linear cylinder 9, and the slider 6 is supported in the middle The crossbeam 10 and the linear cylinder 9 are supported on the middle crossbeam 10, and the bottom of the middle crossb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com