Cutter lifting mechanism of sugarcane combined harvester

A machine cutter, sugarcane technology, applied in cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of low rigidity, poor cutting quality, and large vibration of cutters, and achieve high cutting quality, easy maintenance and repair. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

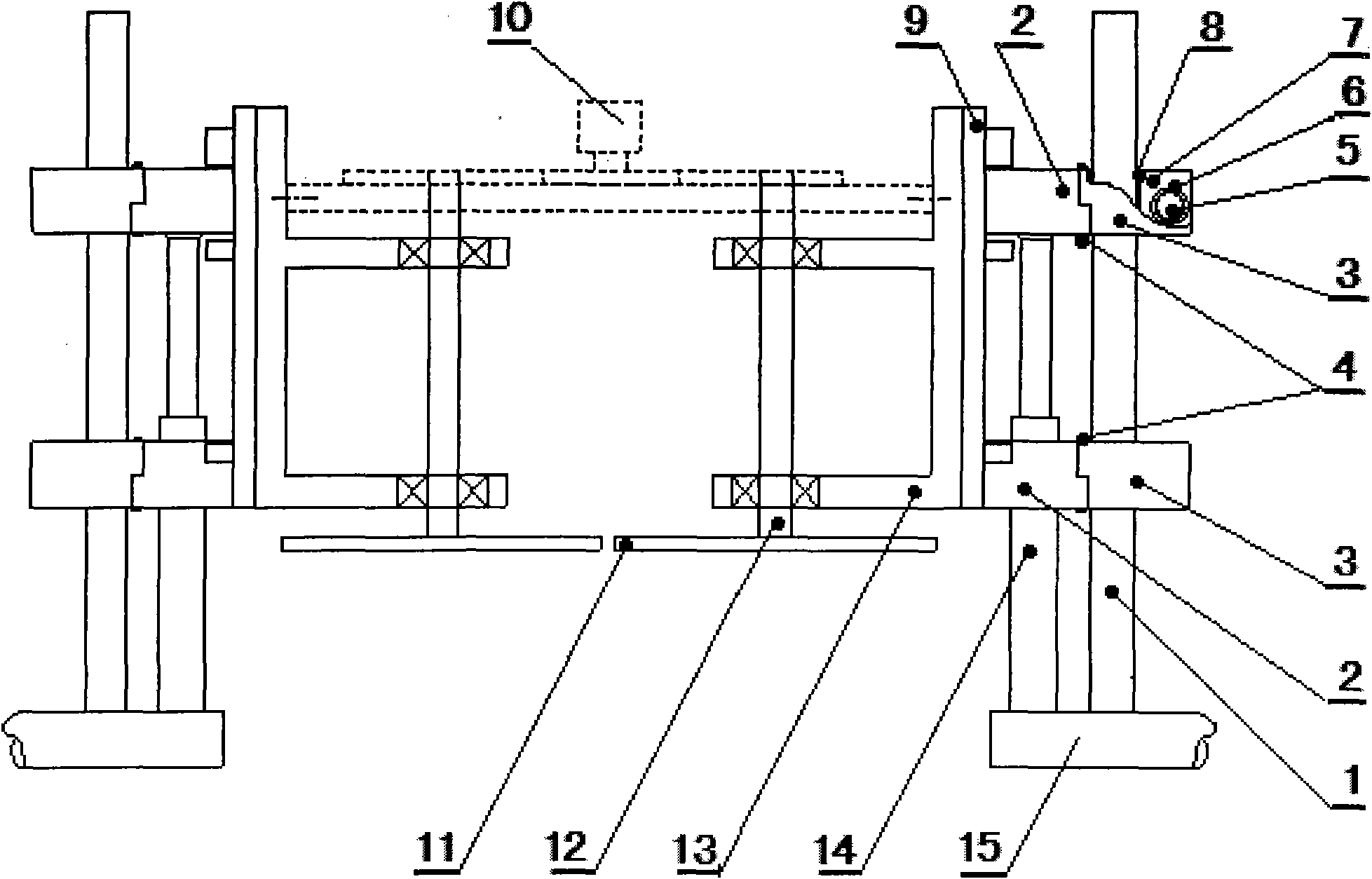

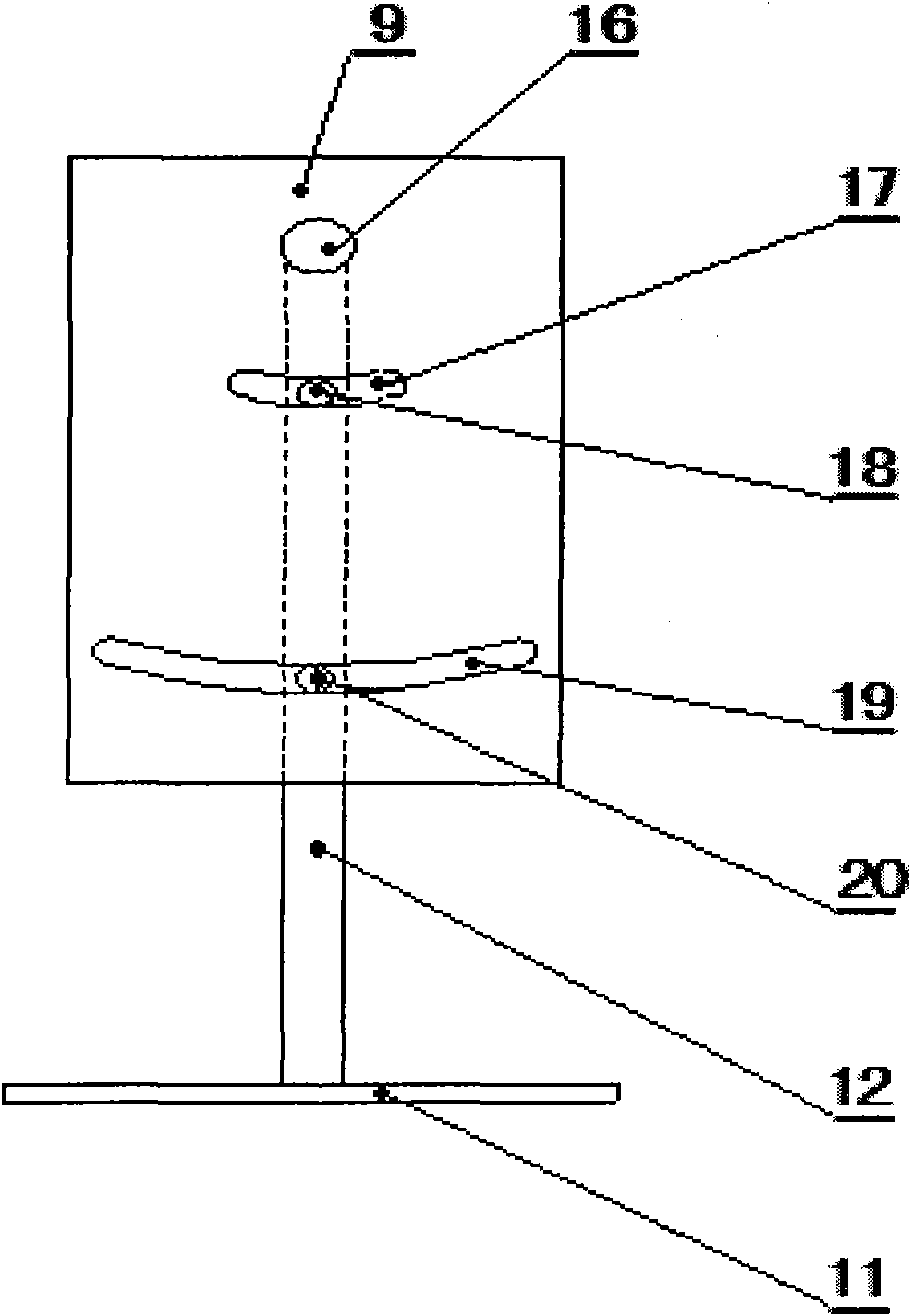

[0031] The sugarcane combine harvester cutter lifting mechanism includes a lifting hydraulic cylinder (14), a stroke guide rod (1), a linkage constant clamping device (2) and a cutter head angle adjustment frame (9). The cylinder body of the lifting hydraulic cylinder (14) is fixed on the harvester body frame (15) with bolts, and the end of the piston rod of the lifting hydraulic cylinder (14) is a flange, and is connected with the linkage constant clamping device (2) with bolts. connect. The stroke guide rod (1) is a circular metal rod, which is welded and fixed on the harvester body stand (15), and the stroke guide rod (1) stroke length is 0-40cm, and pattern is set to increase friction. The linkage constant clamping device (2) is provided with an occlusal opening, which is composed of a large occlusal surface (7) and a small occlusal surface (3). 3) It can rotate around the occlusal bolt (4), and the elastic clamping layer (8) on the occlusal surface is engaged with both s...

Embodiment 2

[0035] The sugarcane combine harvester cutter lifting mechanism includes a lifting hydraulic cylinder (14), a stroke guide rod (1), a linkage constant clamping device (2) and a cutter head angle adjustment frame (9). The cylinder body of the lifting hydraulic cylinder (14) is fixed on the harvester body frame (15) with bolts, and the end of the piston rod of the lifting hydraulic cylinder (14) is a flange, and is connected with the linkage constant clamping device (2) with bolts. connect. The stroke guide rod (1) is a square metal rod, which is welded and fixed on the harvester body stand (15), and the stroke guide rod (1) stroke length is 0-40cm, and pattern is set to increase friction. The linkage constant clamping device (2) is provided with an occlusal opening, which is composed of a large occlusal surface (7) and a small occlusal surface (3). 3) It can rotate around the occlusal bolt (4), and the elastic clamping layer (8) on the occlusal surface is engaged with both sid...

Embodiment 3

[0039] The sugarcane combine harvester cutter lifting mechanism includes a lifting hydraulic cylinder (14), a stroke guide rod (1), a linkage constant clamping device (2) and a cutter head angle adjustment frame (9). The cylinder body of the lifting hydraulic cylinder (14) is fixed on the harvester body frame (15) with bolts, and the end of the piston rod of the lifting hydraulic cylinder (14) is a flange, and is connected with the linkage constant clamping device (2) with bolts. connect. Stroke guide rod (1) is rhombus plastic alloy rod, is fixed on the harvester body stand (15), and travel guide rod (1) stroke length is 0-40cm, and pattern is set to increase friction. The linkage constant clamping device (2) is provided with an occlusal opening, which is composed of a large occlusal surface (7) and a small occlusal surface (3). 3) It can rotate around the occlusal bolt (4), and the elastic clamping layer (8) on the occlusal surface is engaged with both sides of the cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com