Electric wheel hub motor

A hub motor and electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve problems such as unsatisfactory braking effect, weak braking force, heavy hub motor weight, etc., and achieve good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

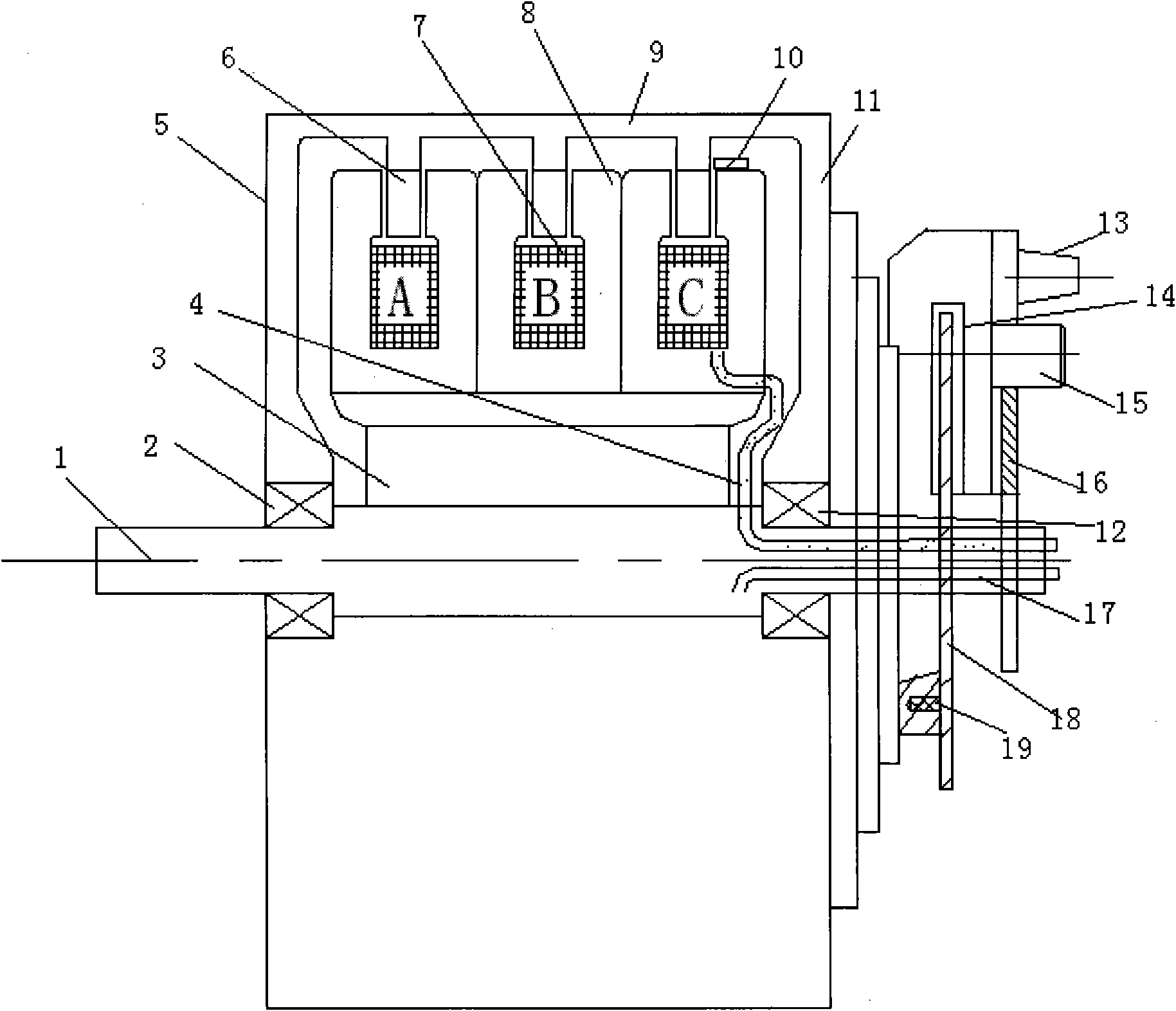

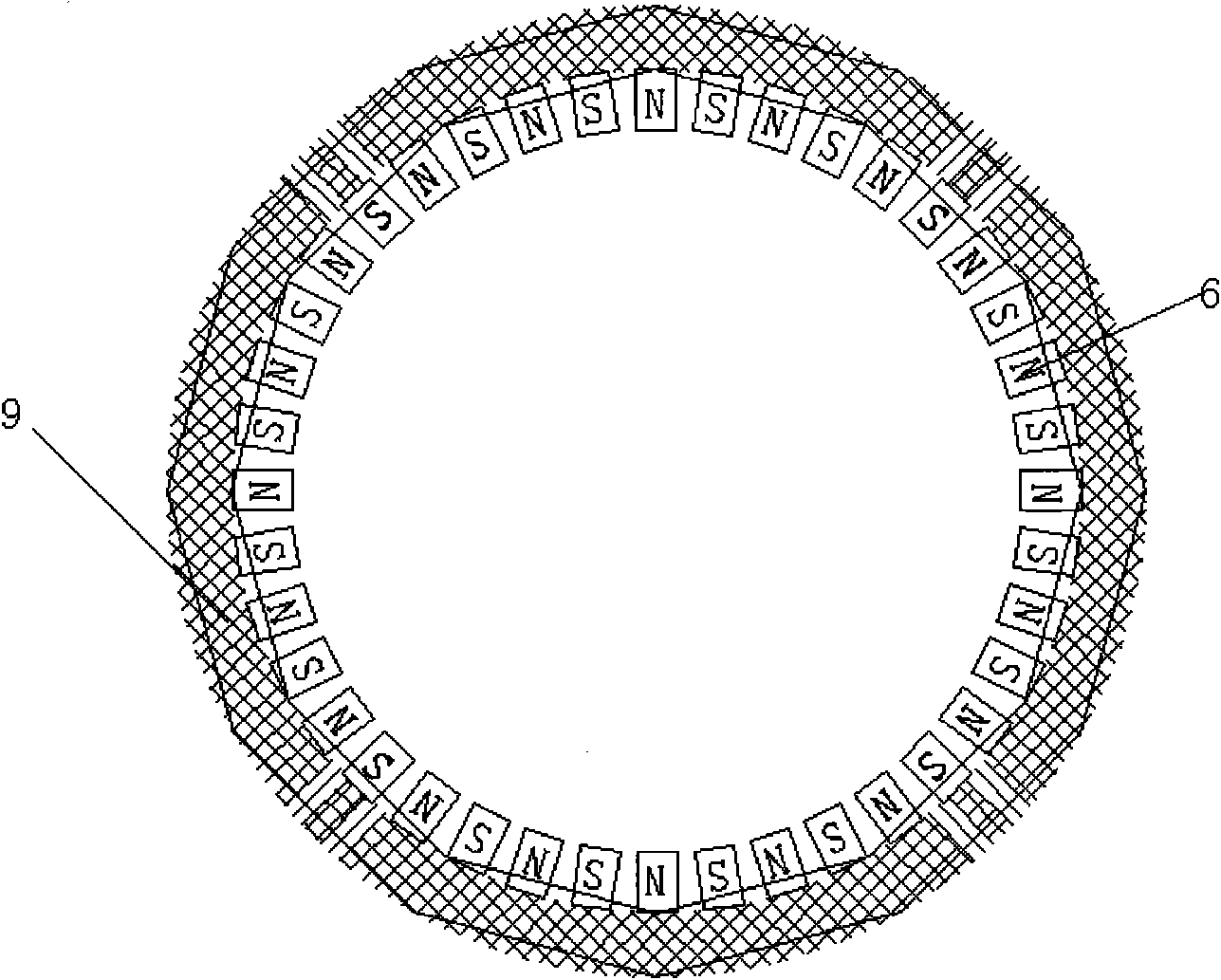

[0014] like figure 1 As shown, the present invention includes a shaft 1, bearings 2 and 12, a bracket 3, a permanent magnet pole 6, an armature winding 7, a silicon steel sheet yoke 8 and a casing 5, and the casing 5 includes a side wall 9 and an end cover 11. The bearings 2 and 12 are set on the shaft 1, the permanent magnet poles 6 are bonded on the side wall 9, the end cover 11 is connected with the bearings 2 and 12, and together with the permanent magnet poles 6 form the motor rotor; the armature winding 7, the silicon steel sheet The yoke 8 and the bracket 3 are fixedly connected with the shaft 1 to serve as a motor stator. The lead wire 4 and the winding tap lead wire are drawn out of the hollow part of the shaft 1 and connected with the additionally equipped open-loop controller. A Hall position sensor 10 is arranged on the silicon steel sheet yoke close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com