Automatic circular welding machine for plate roller plug

A plug, automatic technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The concentricity of the circle, the gap between the plug and the pipe is not easy to control, etc., to achieve the effect of reducing the turning allowance, good dynamic balance performance, and reducing the consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

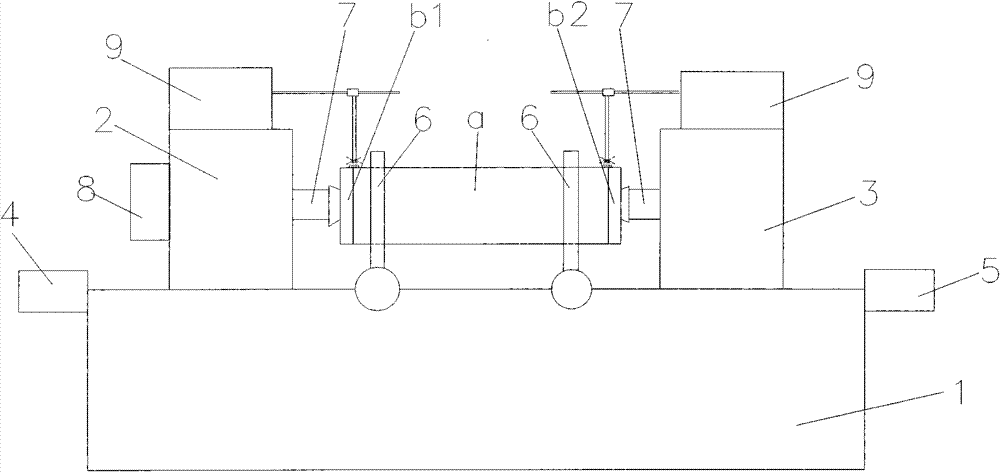

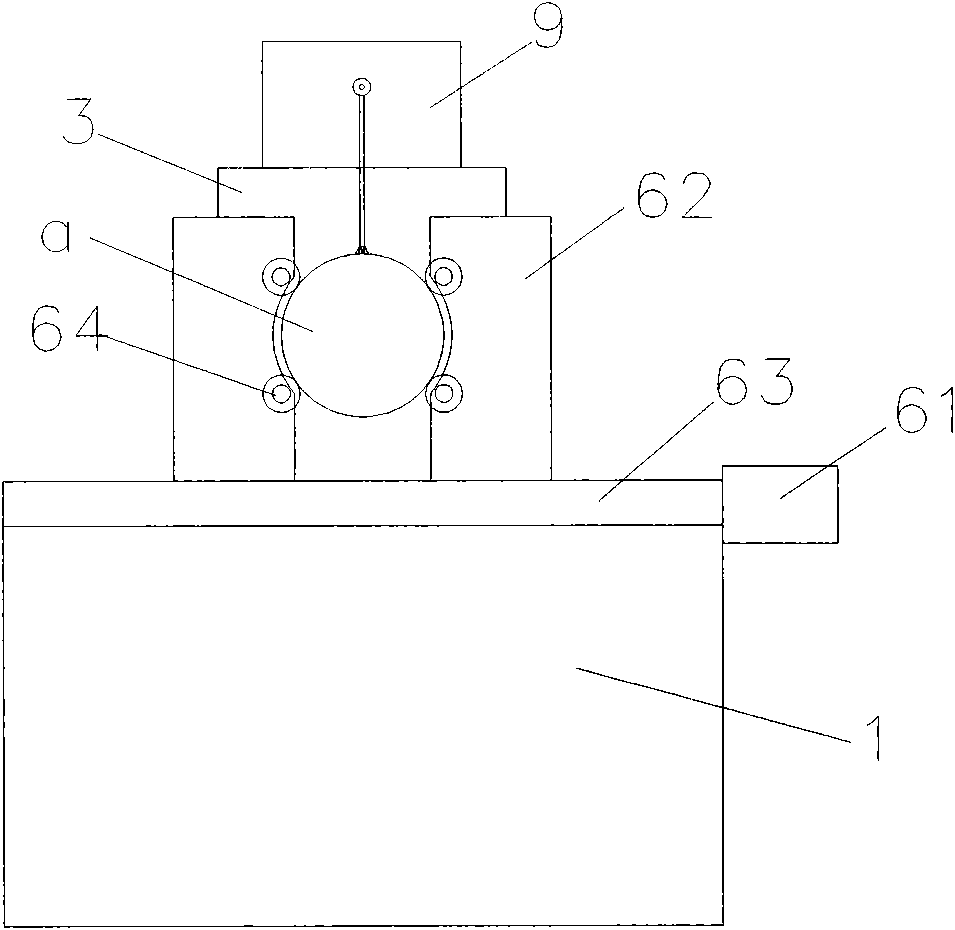

[0016] see figure 1 , the version roller plug automatic ring welding machine of the present invention comprises a bed 1, a bedside box 2 installed at the head of the bed and a tailstock 3 installed at the end of the bed, and the bedside is provided with a drive for driving the headstock 2 to move left and right The first deceleration motor 4 is provided with the second deceleration motor 5 for driving the tailstock 3 to move left and right at the end of the bed, and also includes two four-wheel alignment center frames 6, two tops 7, the third deceleration motor 8 and two welding machines 9. Two four-wheel positioning center frames 6 are arranged at intervals in the middle of the bed for positioning the pipe a. The two tops 7 are respectively rotatably installed on the headstock and the tailstock and are arranged opposite to each other. The third reduction motor 8 is installed on the bedside box and links to each other with the top drive installed on the bedside box and can dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com