Cassava grinding equipment

A crushing equipment and cassava technology, which is applied in the direction of solid separation, wet separation, grain processing, etc., can solve the problems of complex structure, non-continuous sand removal treatment, closed working environment, etc., and achieve the effect of simple structure and convenient sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

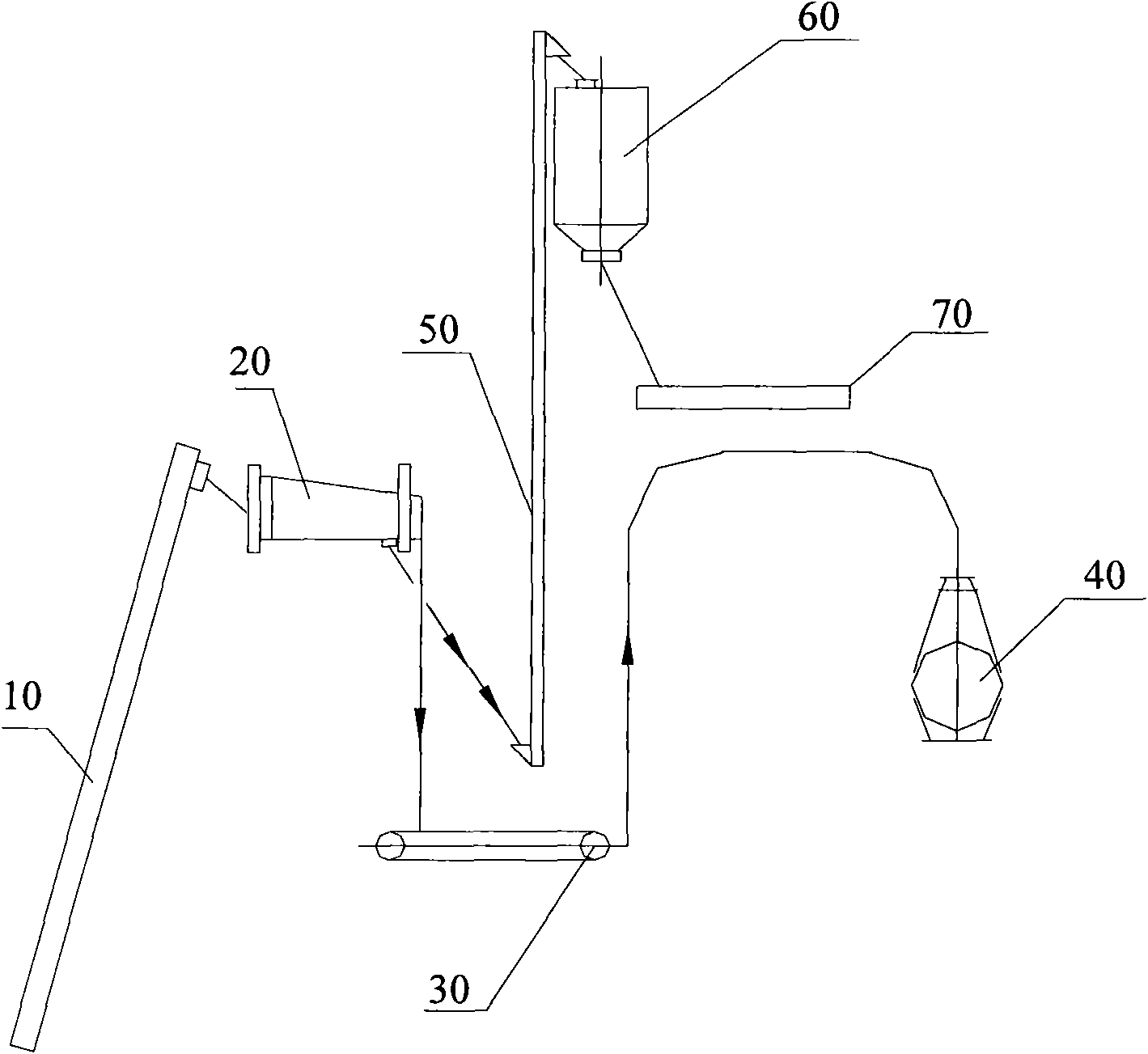

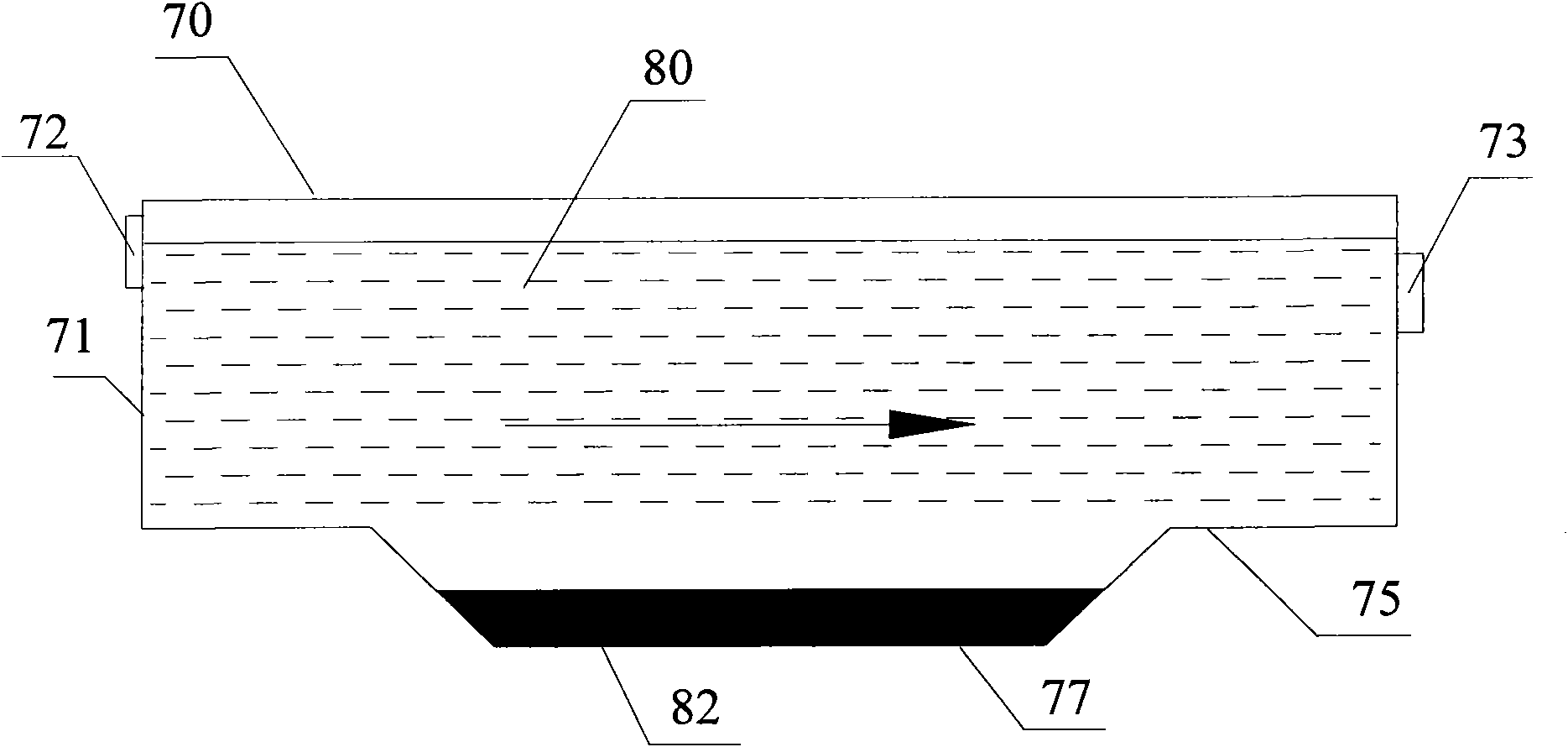

[0011] Such as figure 1 with figure 2 As shown, the cassava pulverizing equipment of the present invention comprises the first conveying device 10, particle classifying device 20, second conveying device 30, pulverizing device 40, the 3rd conveying device 50 and collection device 60 and settling tank 70, particle classifying device 20 classify the cassava particles from the first conveying device 10, and pass through the second conveying device 30 and the third conveying device respectively by the large cassava particles obtained after classification and the small particle mixture comprising cassava small particles and sand grains 50 is supplied to the pulverizing device 40 and the collection device 60 for feeding, and the collection device 60 is connected to the sand settling tank 70, and the sand settling tank 70 includes a tank body 71, an inlet 72 and an outlet 73, and the small particle mixture discharged by the collection device 60 or The slurry formed with water enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com