Preparation method of molecular sieve catalyst

A molecular sieve and catalyst technology, applied in the field of catalyst preparation, can solve problems such as unreported, and achieve the effects of easy industrial amplification, high selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the molecular sieve catalyst provided by the present invention comprises the steps of carrying out pickling treatment and surface silanization treatment on the molecular sieve with crystalline aluminosilicate structure. The prepared catalyst has excellent catalytic activity and is applicable to methanol, dimethyl In the method of converting ether into gasoline components, it has the advantages of high selectivity of the target product and good repeatability of catalytic performance. The preparation method of the catalyst is simple, easy to operate, and easy to realize industrial scale-up.

[0016] In the method provided by the present invention, the molecular sieve is well known to those skilled in the art, such as silica-alumina molecular sieves, heteroatom molecular sieves and other molecular sieves containing crystalline aluminosilicate structures, specifically including ZSM-5, ZSM-45, ZSM-34 , MCM-22, Y, BETA, etc., among which ZSM-5 is pre...

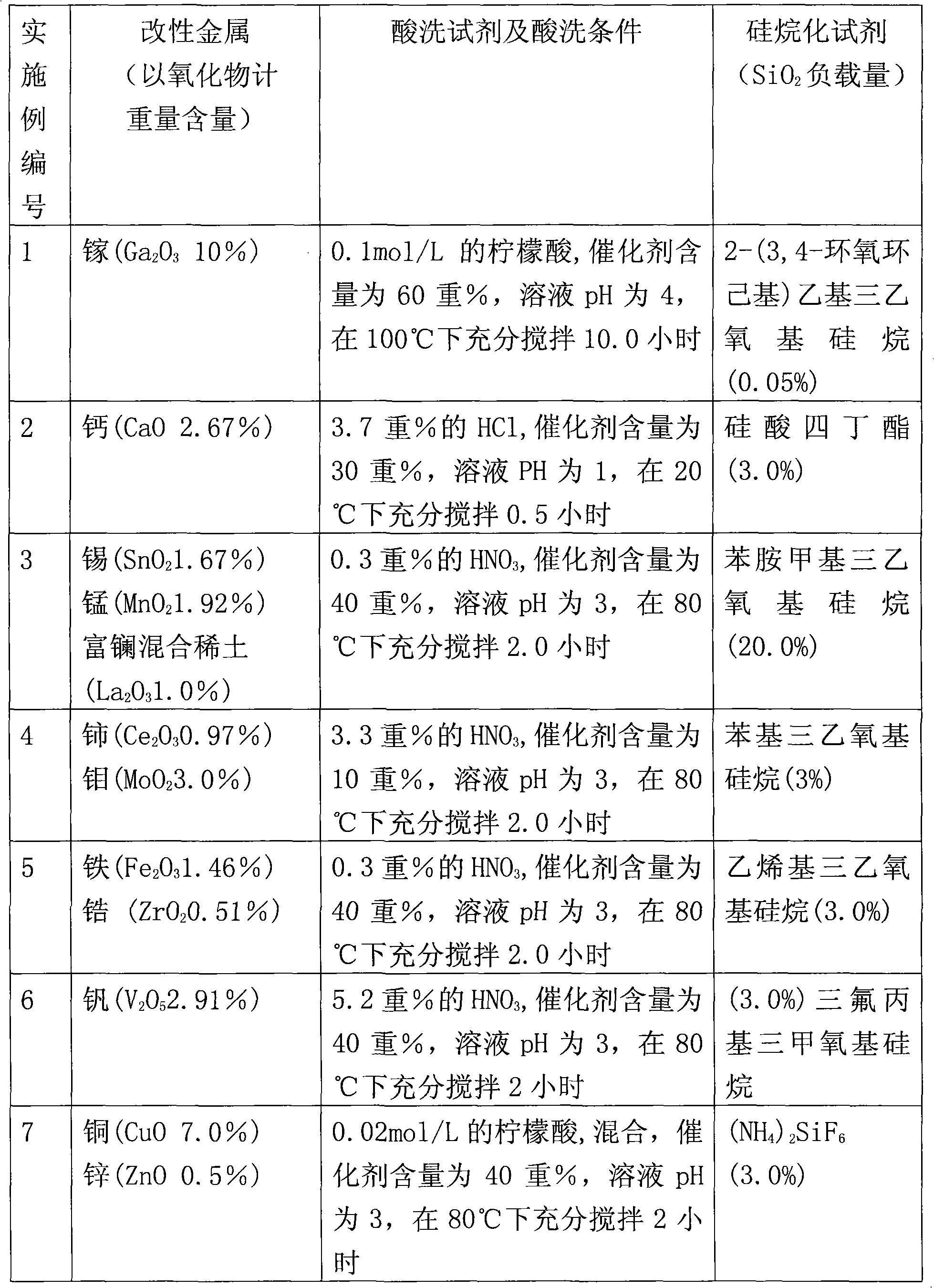

Embodiment 1

[0032] 50mL of Ga(NO with a concentration of 1.10mol / L 3 ) 3 (analytical pure, Guangzhou Boyi Chemical Co., Ltd.) and 16.4mL, the concentration is 0.1mol / L citric acid (industrial product, the same below) mix evenly, add 99.53g ZSM-5 molecular sieve (Qilu Catalyst Factory) in the above solution Production, solid content 85.0% by weight, Na 2 O<0.06%), the pH of the solution is 4, fully stirred at 100°C for 10 hours, filtered, dried at 120°C for 4 hours, and then calcined at 550°C for 4 hours to obtain gallium-modified ZSM-5 molecular sieve Z1 .

[0033] Dissolve 0.19g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane in 200g of ethanol to form a solution, then react Z1 with the above solution at 70°C under reflux, and then dry at 120°C 4 hours, baked at 540°C for 24h in flowing air to obtain Ga 2 o 3 The content is 10% by weight, and silanized (SiO 2 ZSM-5 molecular sieve A with a loading of 0.05% by weight). The composition and preparation parameters of the catalyst are s...

Embodiment 2

[0035] 100mL of Ca(NO with a concentration of 0.45mol / L 3 ) 2 (analytical pure, Shanxi Dongxing Chemical Co., Ltd.) and 33.77g, 3.7% by weight of HCl (analytical pure, produced by Beijing Chemical Plant, the same below) were evenly mixed. Add 57.33g ZSM-5 molecular sieves (production of Qilu Catalyst Factory, solid content 85.0% by weight, Na 2 O<0.06%), the pH of the solution is 1, fully stirred at 20°C for 0.5 hours, filtered, dried at 120°C for 4 hours, and then calcined at 550°C for 4 hours to obtain ZSM-5 molecular sieve Z2 containing calcium.

[0036] Dissolve 8.33g of tetrabutyl silicate in 150g of n-hexane to form a solution, then react Z2 with the above solution at 70°C under reflux, then dry at 120°C for 4 hours, and calcinate at 540°C for 24 hours in flowing air , to get CaO 2 The content is 2.67% by weight and silanized (SiO 2 ZSM-5 molecular sieve B with a loading of 3.0% by weight). The composition and preparation parameters of the catalyst are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com