Method for preparing high-color value concentrated peach clear juice

A technology of color value and clear juice, which is applied in the field of preparation of concentrated peach clear juice with high color value, and can solve the problems of peach browning, chroma and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

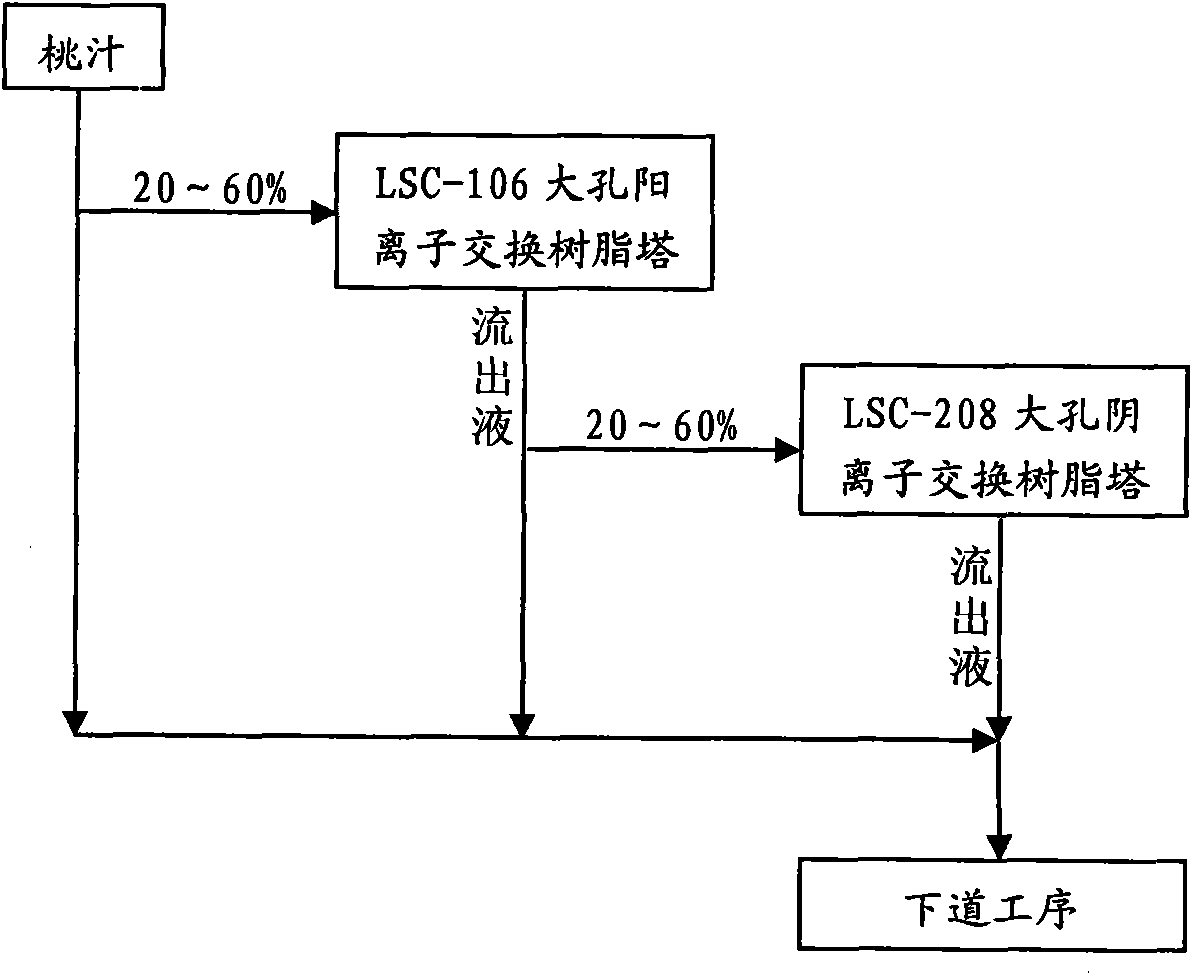

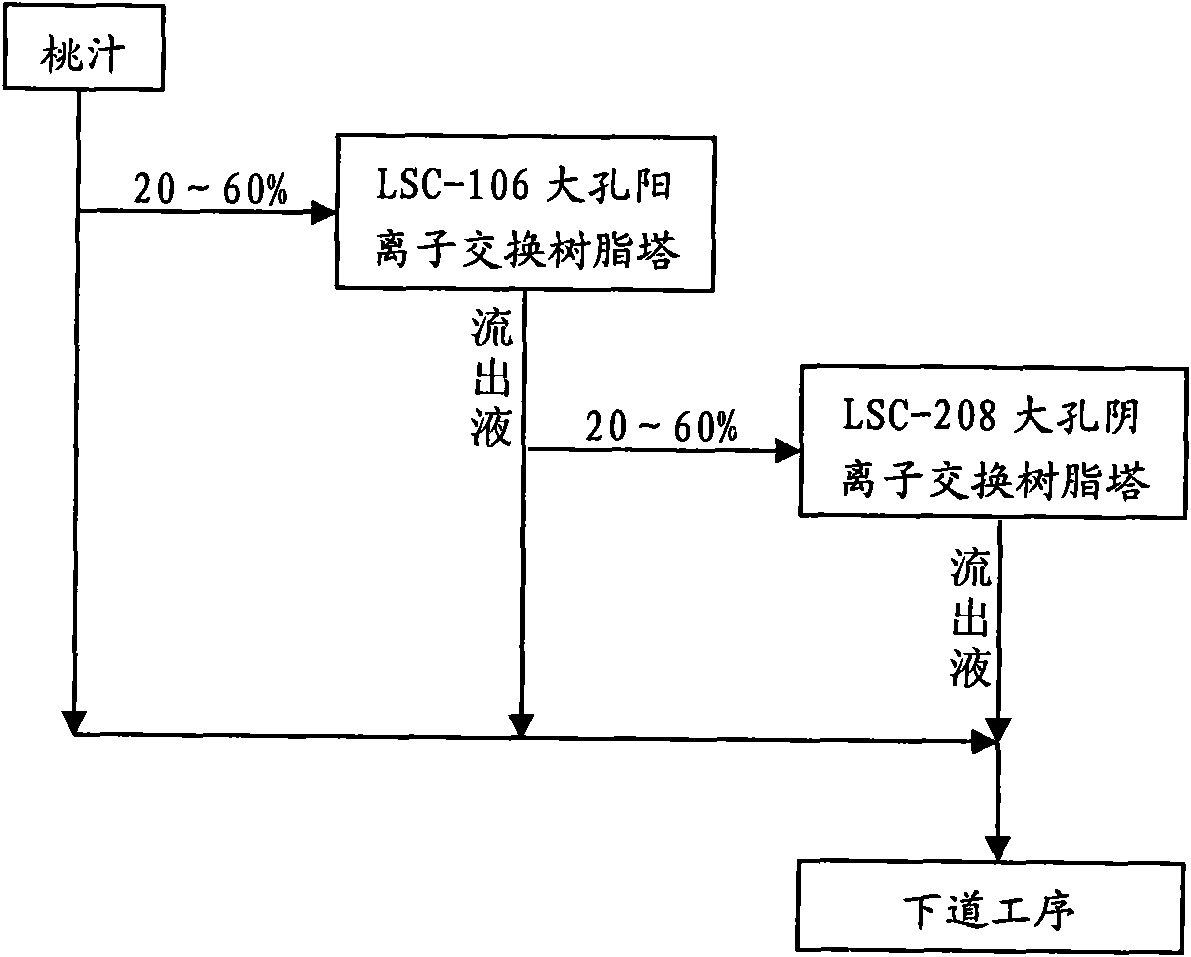

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of concentrated peach clear juice with high color value comprises the steps of:

[0033] A. Raw fruit pretreatment: 1) Cleaning and sorting: select 70 tons of fresh and ripe white peaches as raw fruit and unload them into the fruit trough, and transport the raw fruit to the sorting table while washing with tap water, and sort the raw fruit; 2) Floating washing: transport the selected raw fruit in step 1) to the floating washing tank for cleaning; 3) Crushing: Spray 0.5‰ of fresh fruit weight VC to protect the color of the raw fruit after floating washing, and then use crushing The machine is crushed into pulp, and the peach pits in the pulp are removed by using a 16mm aperture screen.

[0034] B. Squeeze and pre-sterilize the juice: preheat the pulp to 52°C after depitting, cache for 35 minutes, and then press to extract the juice; pass the squeezed juice into the pasteurization device for pre-sterilization, and sterilize at 100°C for 25s.

[003...

Embodiment 2

[0047] The preparation method of concentrated peach clear juice with high color value comprises the steps of:

[0048] A. Raw material fruit pretreatment: 1) Cleaning and sorting: select fresh and ripe peaches as raw material fruit and unload them into the fruit trough, and transport the raw material fruit to the sorting table while washing with tap water, and sort the raw material fruit; 2) Floating Washing: transport the selected raw fruit in step 1) to the floating washing tank for cleaning; 3) crushing: spray 0.5‰ VC color protection of fresh fruit weight to the raw fruit after floating washing, and then use a crusher to break into pulp, and use a sieve with a pore size of 16mm to remove the peach pits in the pulp.

[0049] B. Squeeze and extract juice and pre-sterilize: preheat the pulp to 55°C after depitting, cache for 30 minutes, and then press to extract the juice; pass the squeezed juice into a pasteurization device for pre-sterilization, and sterilize at 105°C for 2...

Embodiment 3

[0058] The preparation method of concentrated peach clear juice with high color value comprises the steps of:

[0059] A. Raw material fruit pretreatment: 1) Cleaning and sorting: choose fresh and ripe peaches as raw material fruit and unload them into the fruit trough, and transport the raw material fruit to the sorting table while washing with tap water, and sort the raw material fruit; 2) Floating Washing: transport the selected raw fruit in step 1) to the floating washing tank for cleaning; 3) crushing: spray 0.5‰ VC color protection of fresh fruit weight to the raw fruit after floating washing, and then use a crusher to break into pulp, and use a sieve with a pore size of 16mm to remove the peach pits in the pulp.

[0060] B. Squeeze and extract juice and pre-sterilize: Preheat the pulp to 50°C after depitting, cache for 40 minutes, and then press to extract the juice; put the squeezed juice into a pasteurization device for pre-sterilization, and sterilize at 95°C for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com