Method and device for monitoring supply power of induction heating device

An induction heating device and induction heating technology, applied in induction heating, measuring device, measuring current/voltage, etc., can solve problems such as uneven quenching and insufficient induction heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

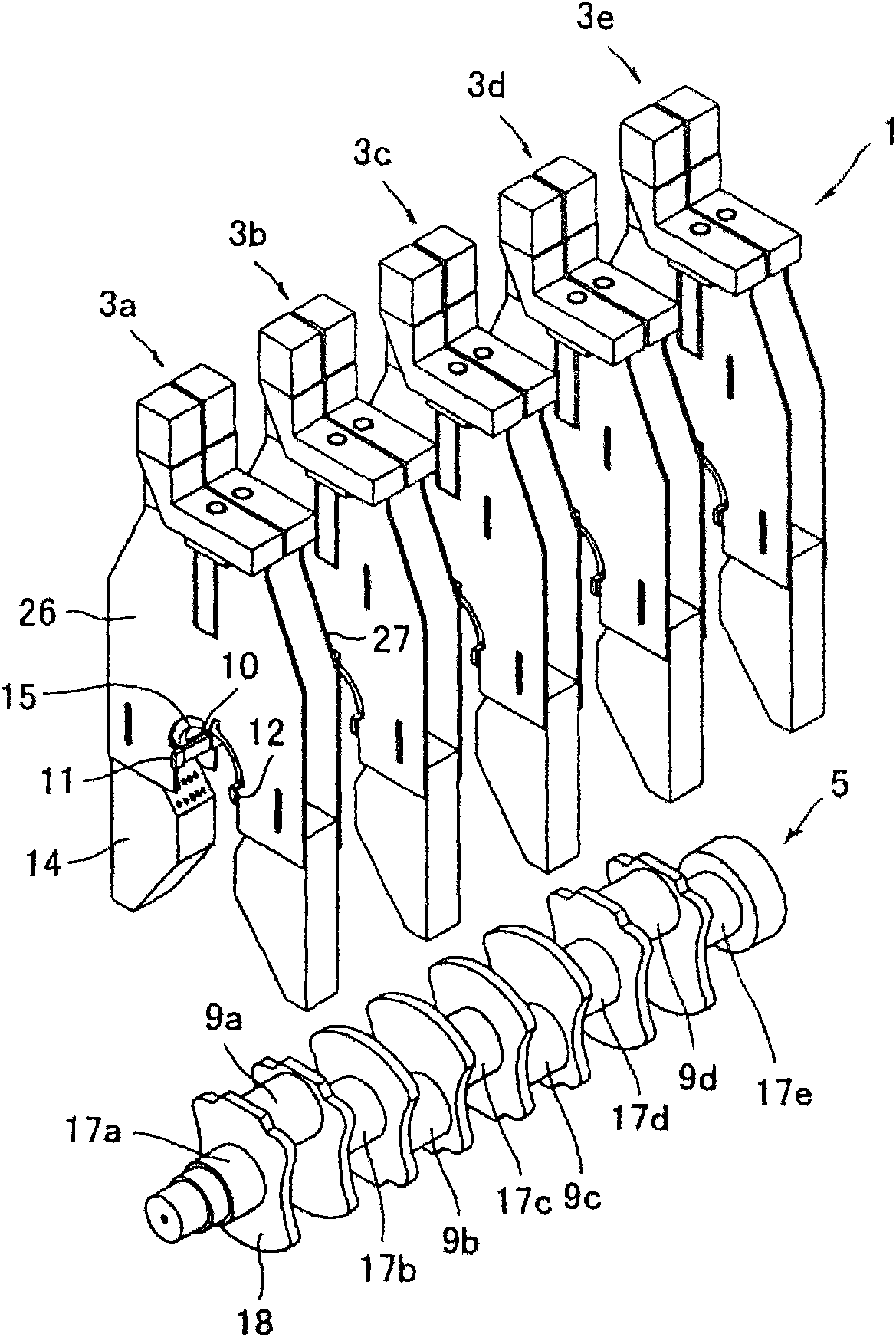

[0027] Such as Figure 4 As shown, the induction heating device 1 has a power supply device 2, a heating coil body 3, a heating coil body moving device 4, a rotation angle detection sensor 7 (rotation angle detection mechanism), and a control device 8 (power detection mechanism). Next, each configuration will be described.

[0028] First, the heating coil body 3 will be described.

[0029] Such as figure 1 , figure 2 As shown, the heating coil body 3 has a conductor 15 formed of a material having both conductivity and durability. Part of the conductor 15 constitutes a heating coil portion 16 that can be arranged oppositely along the peripheral surface of the crankshaft 5 (object to be heated by induction) along the peripheral surface of the crankshaft 5 (object to be heated by induction). The heating coil unit 16 is configured by bending and bending a part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com