Taper detection device

A detection device and taper technology, which is applied in the field of measurement, can solve problems such as large errors, many measurement parameters, and low taper accuracy, and achieve the effects of reducing measurement errors, reducing measurement parameters, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

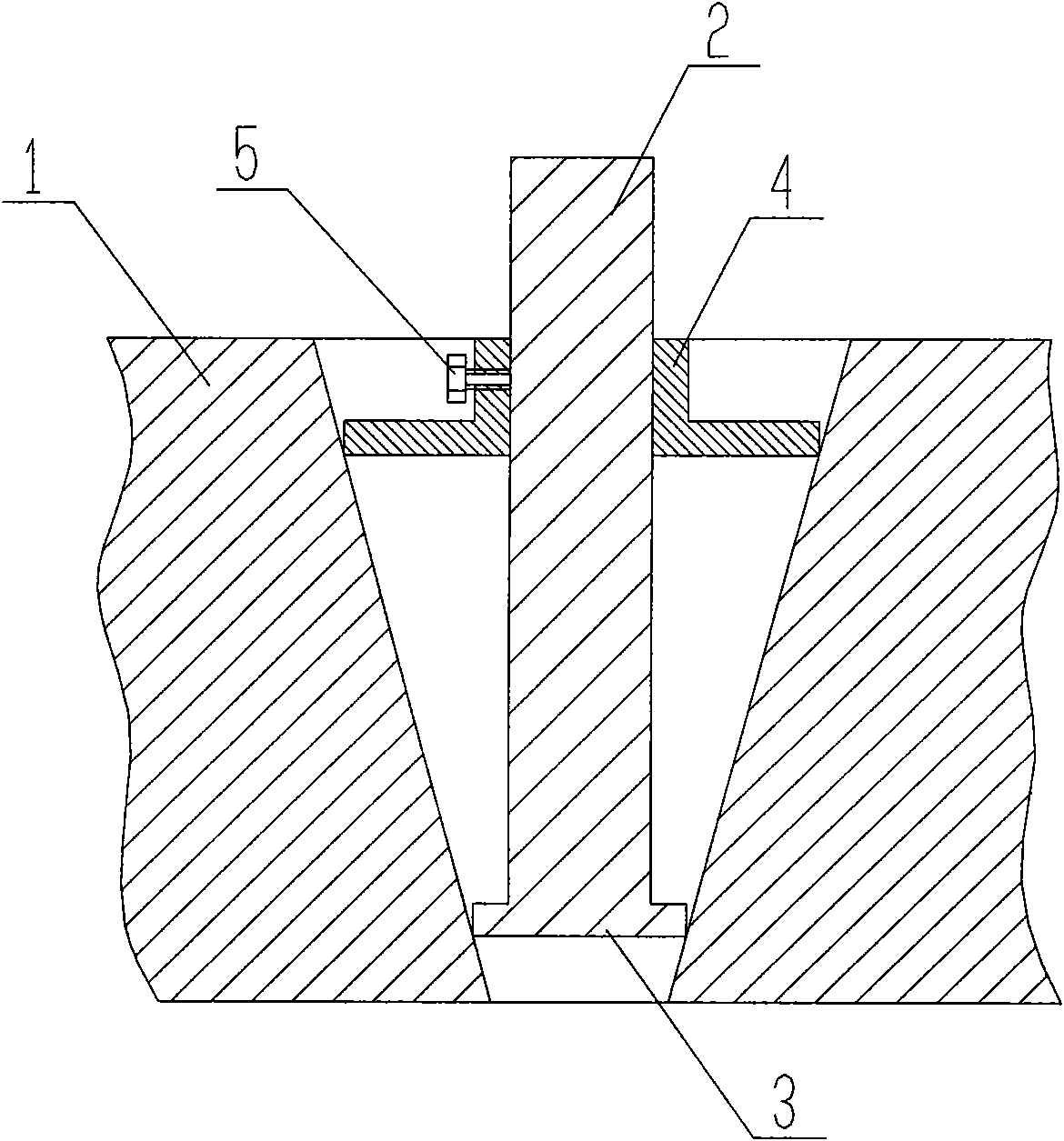

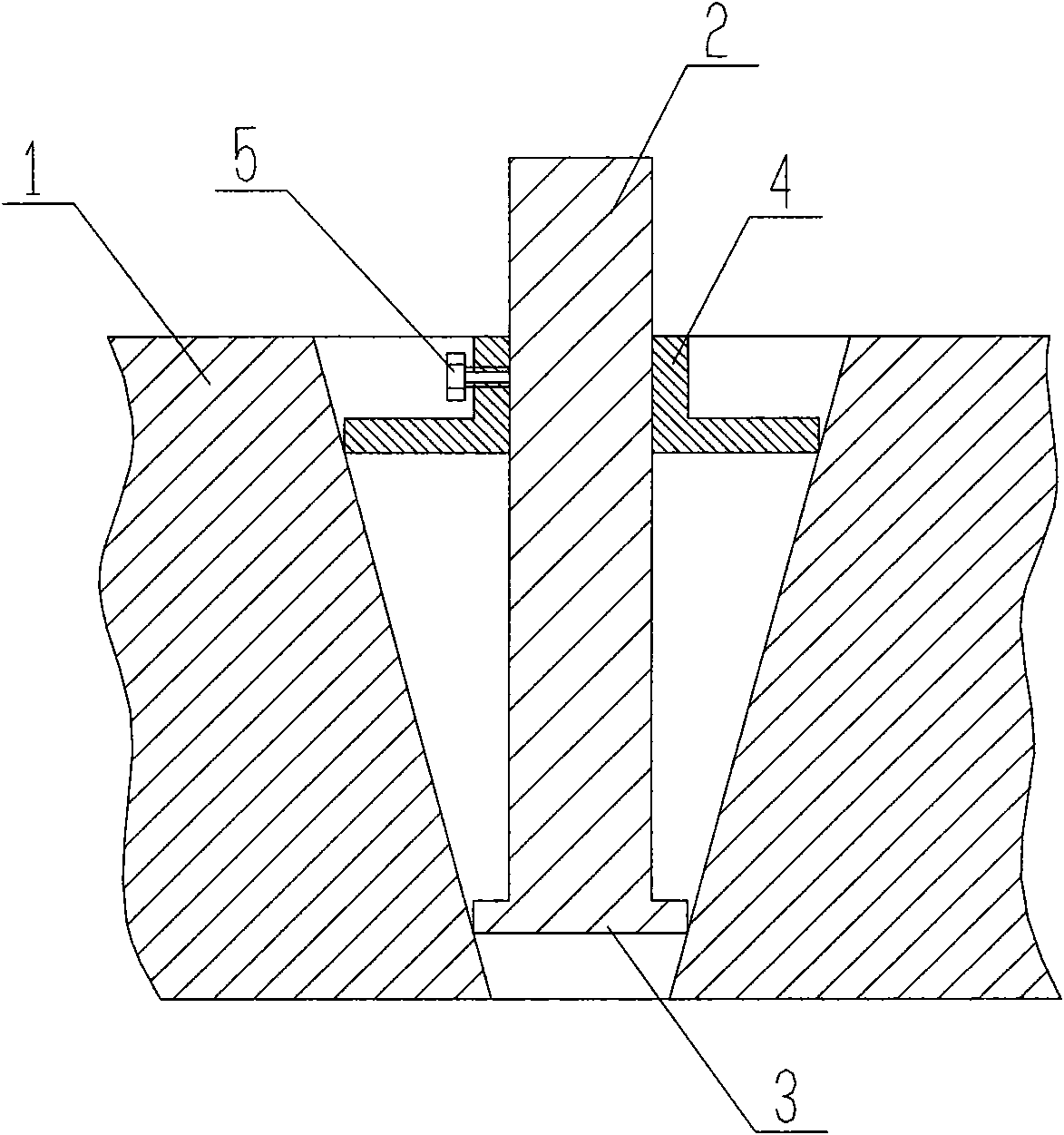

[0013] Such as figure 1 Shown is a structural cross-sectional view of a taper detection device according to the present invention, which mainly includes a mandrel 2, an end disc 3, a moving disc 4 and a top wire 5, and the end disc 3 is placed at one end of the mandrel 2 and connected to the mandrel Fixed, the center of the moving disc 4 is perforated, and the diameter of the hole is slightly larger than the shaft diameter of the mandrel 2. It can be placed on the other end of the mandrel 2 and can slide along the mandrel 2. When the position of the moving disc is snapped into the taper hole of the workpiece 1 Finally, fix the moving disk 4 and the mandrel 2 with the top screw 5, wherein the disk surfaces of the end disk 3 and the moving disk 4 should be perpendicular to the spindle, and the diameter of the moving disk 4 is larger than the diameter of the end disk 3, which can be determined according to actual needs Different specifications are produced, but for the convenienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com