Sliding-sleeve multi-head nicking tool

A sliding sleeve and cutter head technology, which is applied in the field of sliding sleeve multi-head carving knives, can solve the problems of excessive total volume and total weight, high cost of manual carving, and easy damage of blades, etc., and achieves simple structure and convenient installation or disassembly process Fast and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

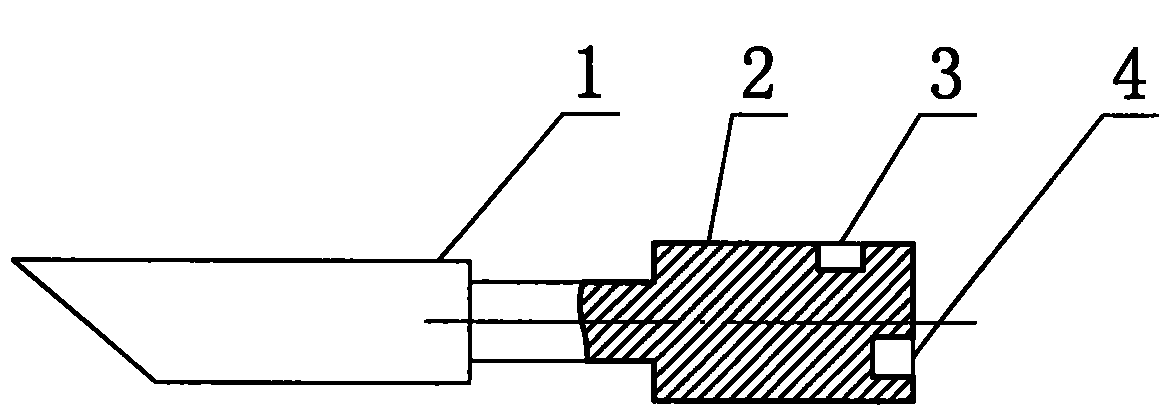

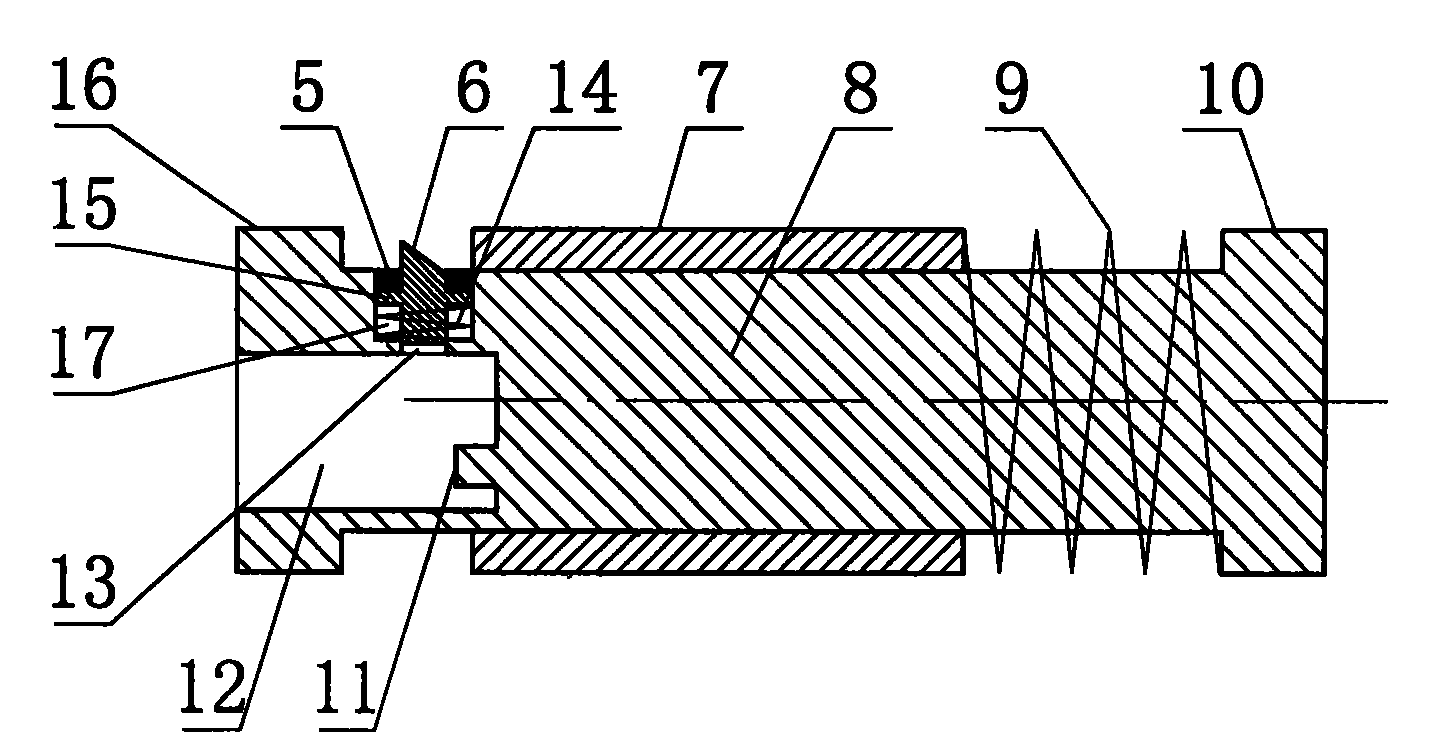

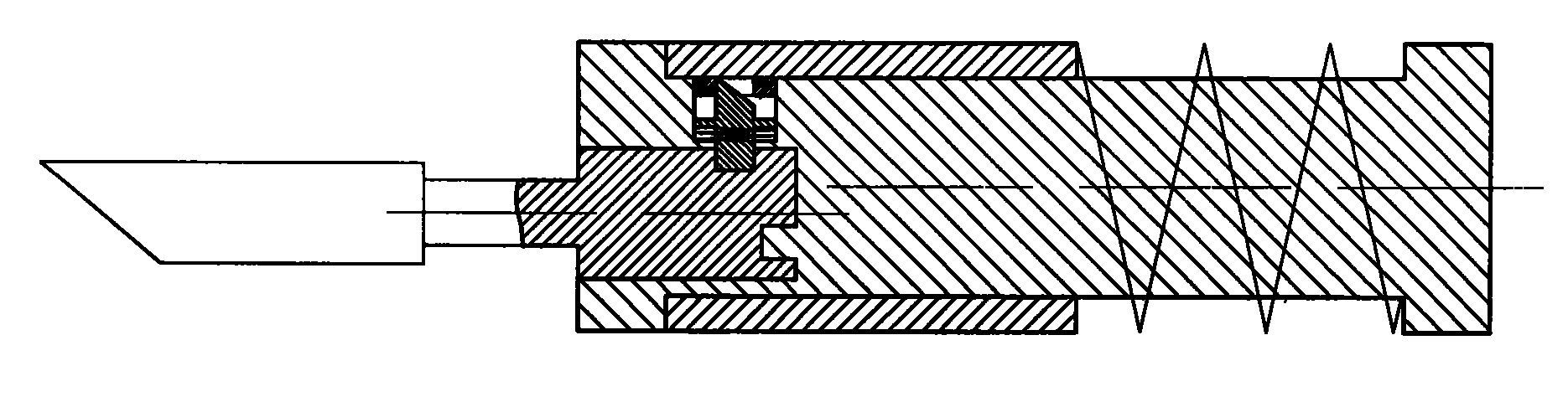

[0028] The sliding sleeve type multi-head carving knife consists of a cutter head 1, a cutter head handle 2, a side hole 3, an end hole 4, a fixed ring 5, a locking lever 6, a sliding sleeve 7, a handle 8, a sliding sleeve spring 9, a fixed spring plate 10, and an eccentric Column 11, assembly hole 12, locking hole 13, locking lever spring 14, locking lever sheet 15, retaining ring 16 and locking cavity 17 constitute.

[0029] Wherein the cutter head handle 2 is positioned at the tail end of the cutter head 1 and is an integral body with the cutter head 1, the cutter head handle 2 is cylindrical, and side holes 3 are arranged on the side wall of the cutter head handle 2, and the end of the cutter head handle 2 There is an end hole 4 at a non-center position, and both the side hole 3 and the end hole 4 are blind holes.

[0030] The handle 8 is cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com