Cooling system inside variable frequency generator unit

A technology for cooling systems and generator sets, applied in electric components, cooling/ventilation devices, electrical components, etc., can solve the problems of reduced work reliability and life, increased cost, and large volume, avoiding large axial dimensions, The effect of reducing the axial size and compact structure of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

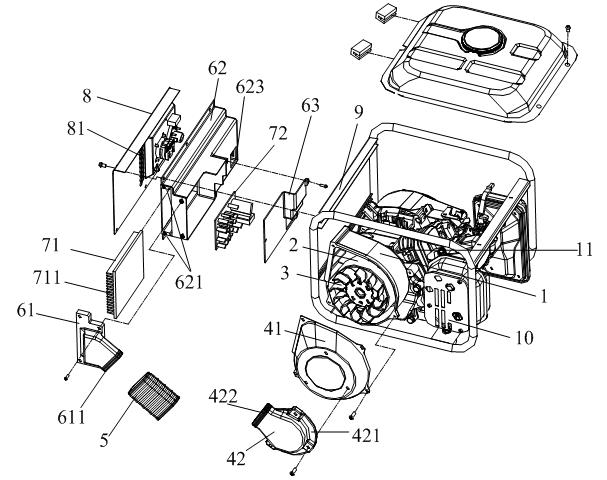

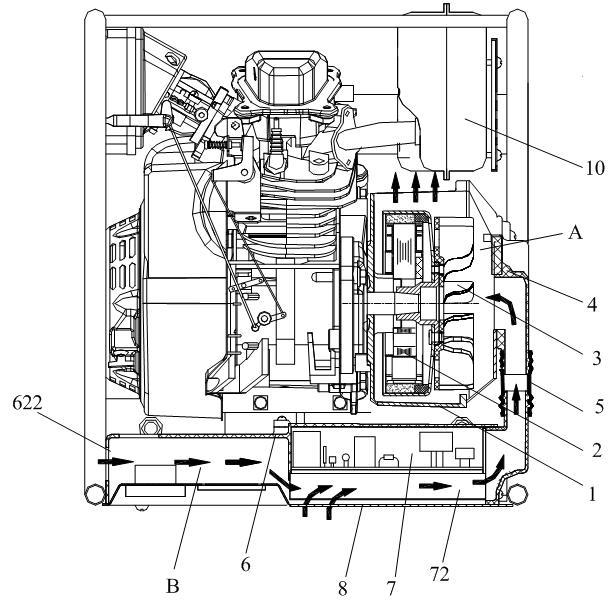

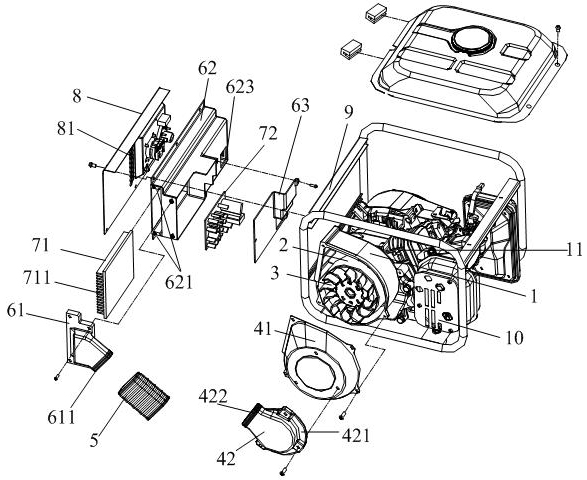

[0017] Such as figure 1 and figure 2 As shown, the cooling system inside the frequency conversion generator set of the present invention mainly includes a generator air guide cover 1, a generator 2, fan blades 3, an air guide cover plate 4, a hose 5, an inverter controller 7, and an inverter air guide Body 6, control panel 8. Wherein, the air guide cover 4 includes an air guide cover 41 and a generator air guide joint 42 . The inverter air guide body 6 includes an inverter air guide slot 62 , an inverter air guide joint 61 and a wind deflector 63 . The generator 2 and the fan blades 3 are inside the generator wind guide cover 1, and together with the wind guide cover plate 4 constitute the generator cooling ventilation folder A; the inverter controller 7 is fixed in the inverter air guide slot on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com